COB module light source for enhancing central light intensity and manufacturing method

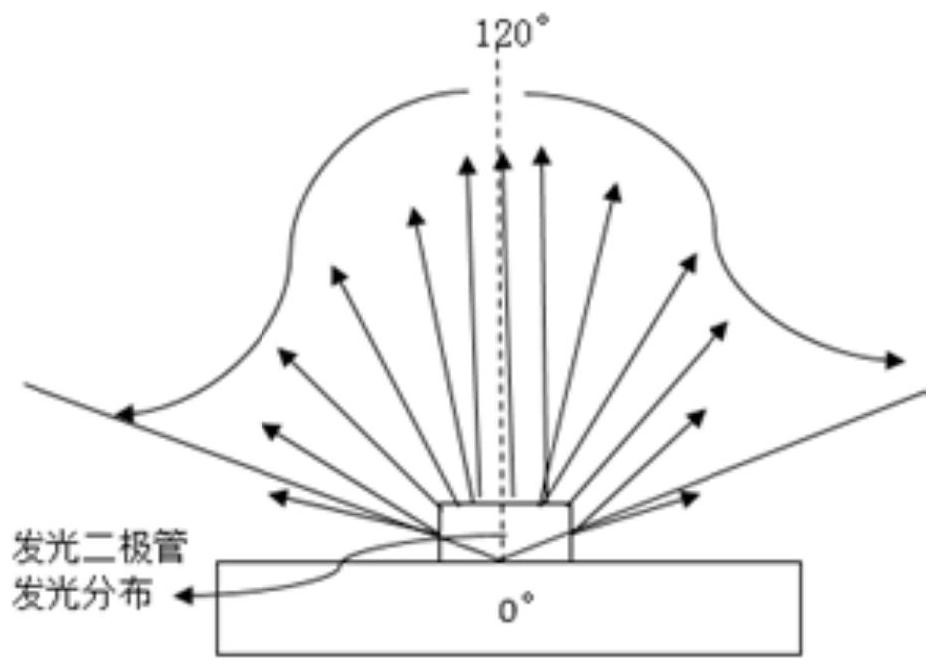

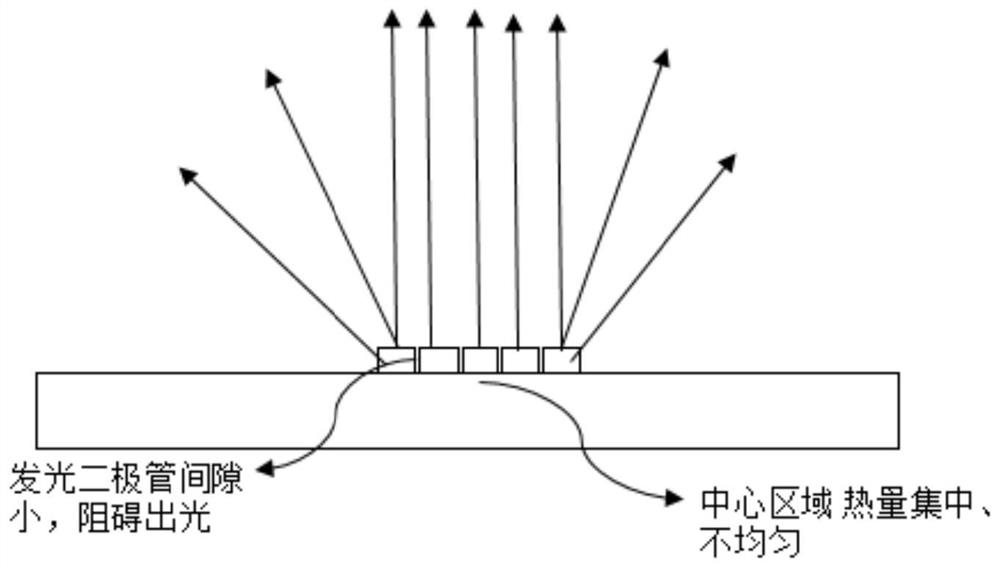

A module and light source technology, which is applied in the direction of light source, fixed light source, and optical elements used to change the spectral characteristics of emitted light, etc. It can solve the problems of large package size and decreased package brightness, so as to reduce the degree of divergence and increase the center The effect of light intensity and narrowing the light angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

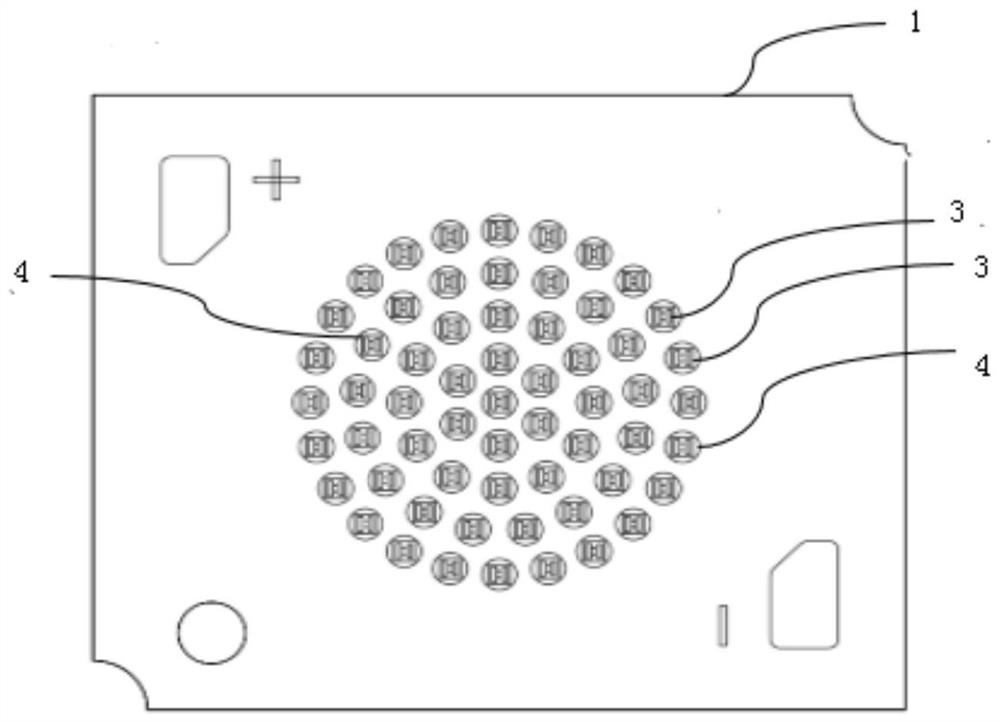

[0046] The COB module light source that enhances the central light intensity includes a substrate 1 , a circuit layer 2 arranged on the substrate 1 , several LED chips 3 arranged on the circuit layer 2 , and a silicone cap 4 arranged on the LED chip 3 .

[0047] The light-emitting diode chips 3 are arranged in a plurality of circles from the center of the substrate 1 from the inside to the outside.

[0048] The silica gel cap 4 wraps the four sides and the top surface of the LED, and one or more kinds of fluorescent conversion materials 5 are arranged in the silica gel cap 4 .

[0049] The silicone cap 4 corresponds to a single light-emitting diode chip 3, forming several ring shapes, and the height of the silicone caps 4 placed in the same ring shape is the same, and from the center of the substrate 1 from the inside to the outside direction, the height of the silicone cap 4 increases successively; the height of the outermost silicone cap 4 is the largest, and the height of t...

Embodiment 2

[0055] The COB module light source that enhances the central light intensity includes a substrate 1, a circuit layer 2 arranged on the substrate 1, a number of LED chips 3 arranged on the circuit layer 2, and a silicone ring 6 arranged on the LED chip 3.

[0056] The light-emitting diode chips 3 are arranged in a plurality of circles from the center of the substrate 1 from the inside to the outside.

[0057] The silicone ring 6 wraps the four sides and the top surface of the LED, and the silicone cap 4 is provided with one or more fluorescent conversion materials 5 .

[0058] The silicone rings 6 correspond to the light-emitting diode chips 3 in the same ring-shaped position, forming several ring shapes, and the heights of the silicone rings 6 placed in the same ring-shaped position are the same, and from the bottom of the substrate 1 From the center to the outside, the height of the silicone ring 6 increases sequentially; the height of the outermost silicone ring 6 is the lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com