Emergency rapid cooling rod and manufacturing method thereof

A manufacturing method and fast technology, which can be applied to household refrigeration equipment, heat storage equipment, lighting and heating equipment, etc., can solve problems such as block collapse, uneven internal and external cooling, block shape and size that cannot meet the requirements, and achieve Uniform heat dissipation and prevent collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The invention provides a method for manufacturing an emergency rapid cooling rod, comprising the following steps:

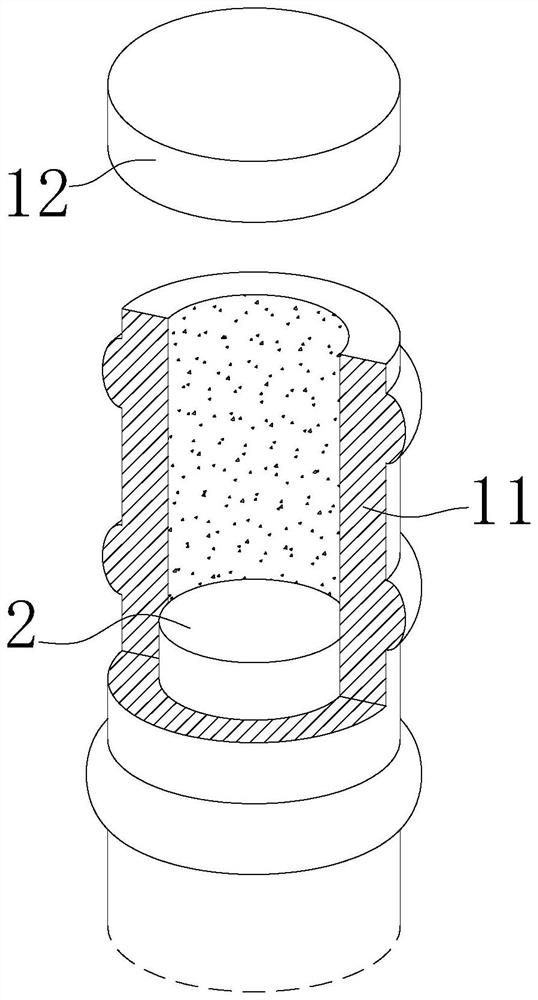

[0043] S1. Manufacture of the column tube 11. The cylindrical hollow tungsten column tube 11 is poured by pouring method, and the inner wall and opening end of the column tube 11 are densely packed with trachoma, thereby forming a rough inner wall and a rough opening of the column tube 11.

[0044] S 1-1. When S2 selects the column tube 11 with an annular protruding ring on the outer wall, turn the column tube 11 whose outer wall is flat and smooth so that the outer wall has an annular protruding ring.

[0045] It should be noted that this embodiment adopts the column tube 11 with an annular protruding ring on the outer wall, and step S1-1 needs to be performed.

[0046] S2, material filling, select the corresponding column tube 11, fill any one of the heat-conducting medium 2 materials in diphenyl ether, pure water ice cubes and molten salt in the column ...

Embodiment 2

[0057] On the basis of the preparation method provided in embodiment one:

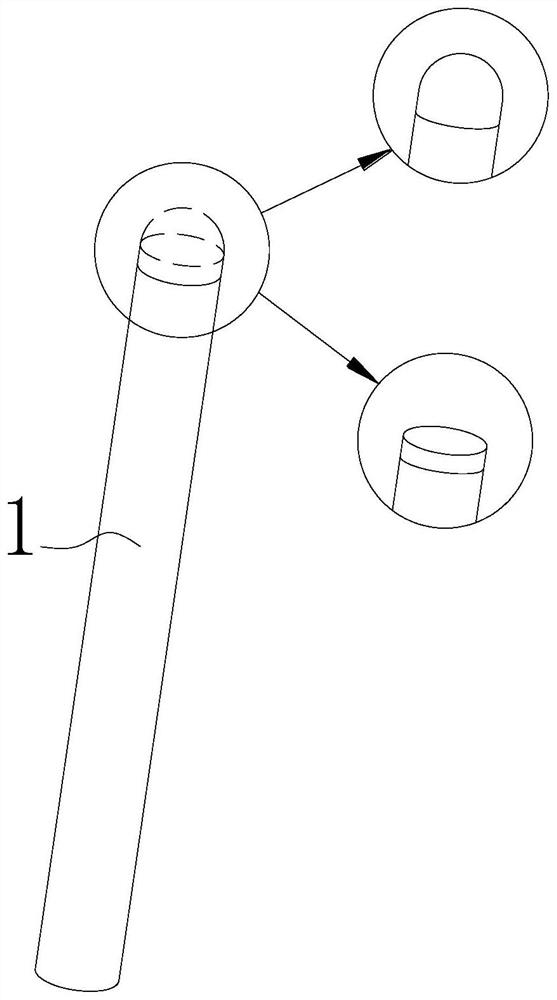

[0058] It should be noted that, in this embodiment, the column tube 11 with a flat and smooth outer wall is used, and step S1-1 is not required.

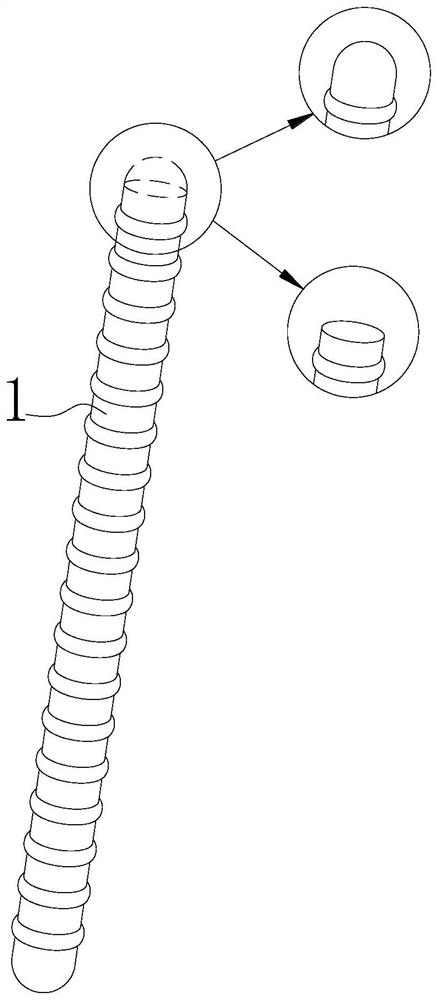

[0059] Such as Figure 1-Figure 3 As shown, the present invention provides an emergency rapid cooling rod made of the above technical solution, its structure includes: a rod body 1, the rod body 1 is a long cylindrical shape, and its interior is hollow and filled with a heat-conducting medium 2 , characterized in that: the inner wall surface of the rod body 1 is rough, the rod body 1 includes a head 12 and a column tube 11, the bottom end of the column tube 11 is closed and an opening is provided at the top, the seal The head 12 is welded and fixed at the opening of the column tube 11, and the rod body 1 is made of metal tungsten.

[0060] The heat conduction medium 2 is one of diphenyl ether, pure water ice cubes and molten salt. In this embodiment, molte...

Embodiment 3

[0065] Such as Image 6 As shown, on the basis of the manufacturing method provided in Embodiment 1, this embodiment adopts the same appearance of the rod 1 as in Embodiment 2, that is, the outer wall of the rod 1 is flat and smooth, and the two ends of the rod 1 are planar. .

[0066] The heat-conducting medium 2 is one of diphenyl ether, pure water ice cubes and molten salts. In this embodiment, pure water ice cubes are selected, and the internal filling rate of the heat-conducting medium 2 in the rod body 1 is 55%. %-85%.

[0067] Such as Image 6 As shown, when using polymethyl methacrylate to custom prepare a 1m*1m*0.5m cube, the outer wall of the rod 1 is first coated with release oil, and then the rod 1 is placed in the casting mold, occupying multiple holes Then pour polymethyl methacrylate into the mold, and polymethyl methacrylate wraps the rod body 1 in the mold to form a hole position. At the same time, after pouring, the outside of the block cools and dissipate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com