High-temperature superconducting three-phase alternating-current cable with compact structure

A three-phase AC, high-temperature superconducting technology, used in superconducting devices, superconducting/high-conducting conductors, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

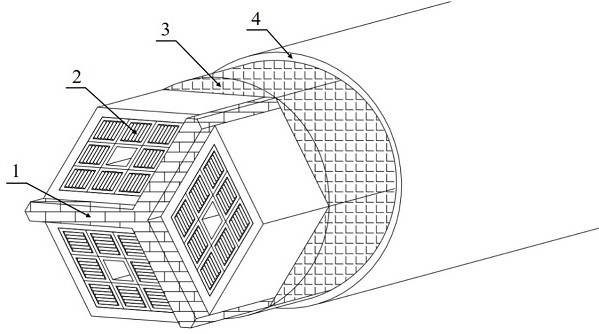

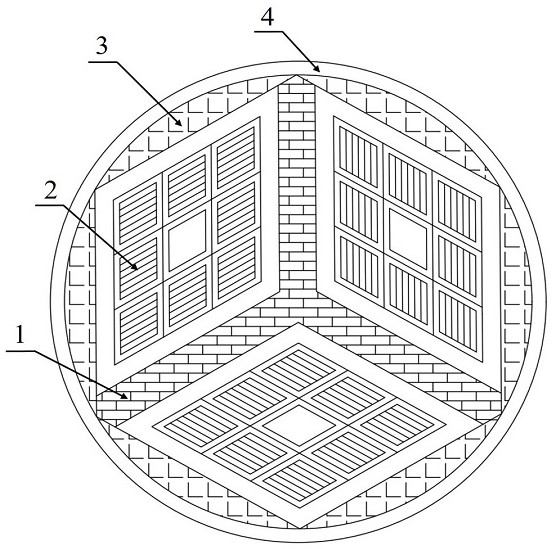

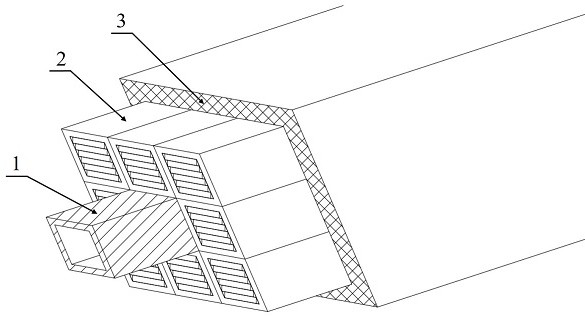

[0022] The invention of a compact high-temperature superconducting three-phase AC cable will be explained in detail below in combination with the accompanying drawings and specific embodiments.

[0023] figure 1 It is a structural schematic diagram of a compact high-temperature superconducting three-phase AC cable involved in the present invention, which includes a metal skeleton (1), three-phase superconducting sub-cables (2), and metal fillers (3) from inside to outside and metal sleeve (4). The three-phase superconducting sub-cables (2) of the present invention are arranged close to the metal skeleton (1), the innermost layer of the three-phase AC cable is the metal skeleton (1), the outermost layer is the metal casing (4), and the three-phase The gap between the superconducting sub-cable (2) and the metal casing (4) is filled with metal aluminum (3). The strip material used in this paper is the same as the 4×0.1 mm second-generation high-temperature superconducting REBCO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com