Roof condensation type photovoltaic power generation device

A photovoltaic power generation and concentrating technology, which is applied to photovoltaic power generation, photovoltaic modules, support structures of photovoltaic modules, etc., can solve the problems of reduced light conduction efficiency of convex lenses, unfavorable high-efficiency photovoltaic power generation, and large photovoltaic power generation devices, and achieves a small structure. , to ensure the efficiency of light transmission, the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

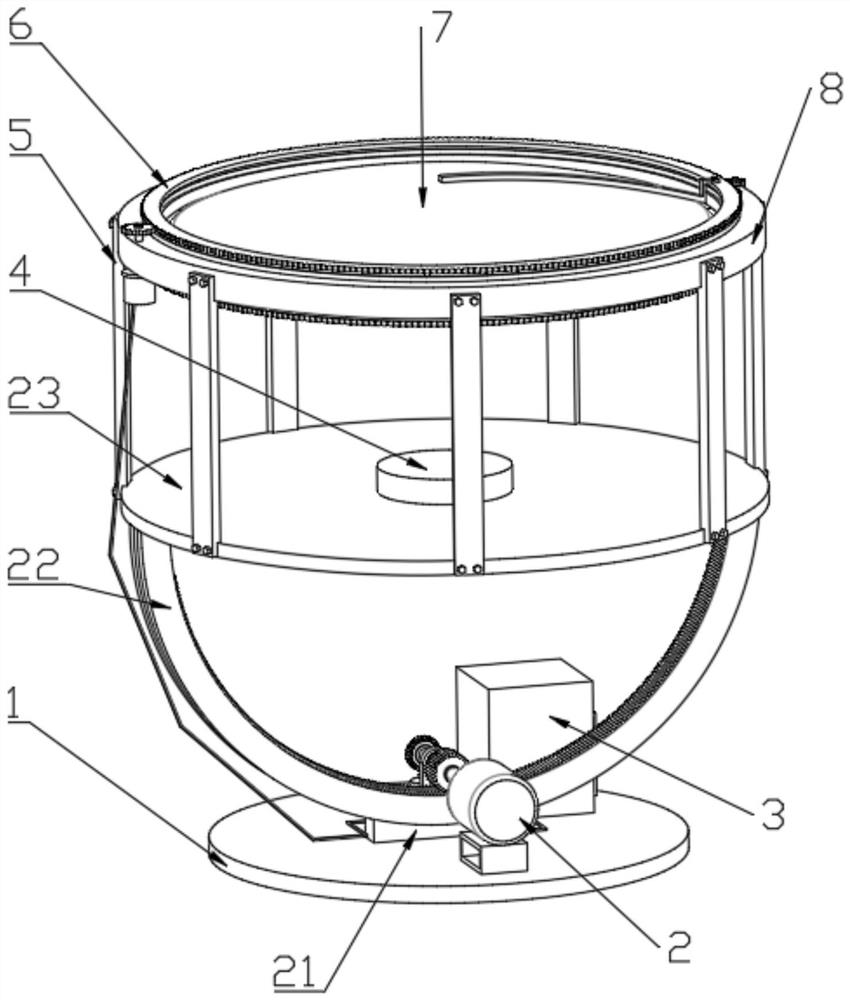

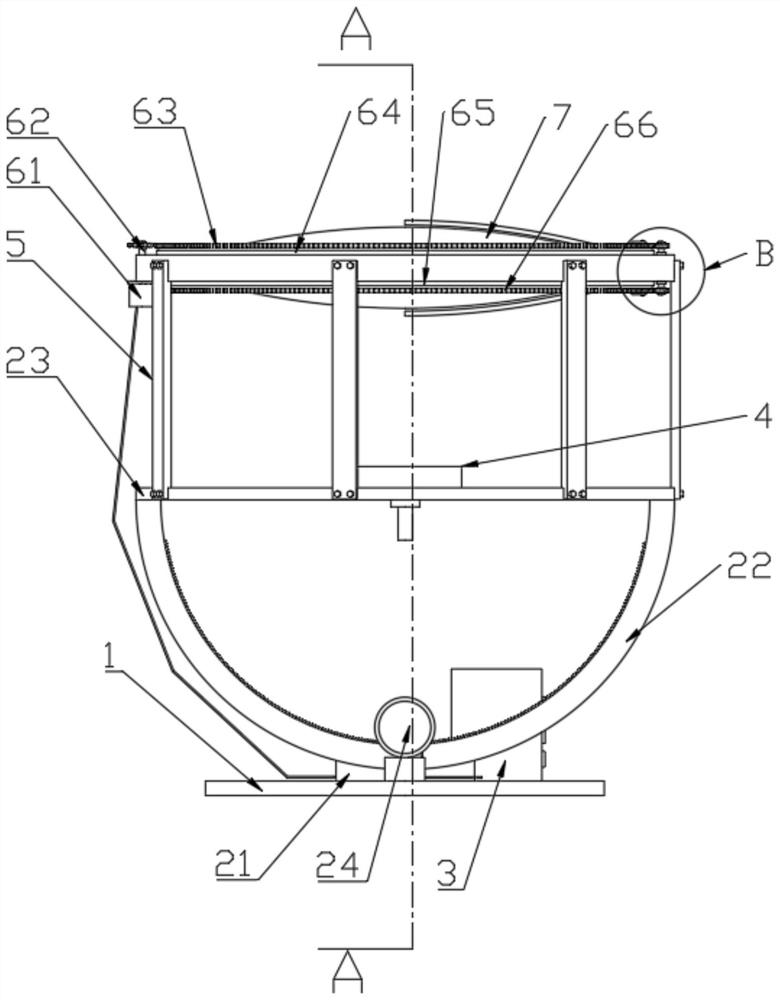

[0051] Such as figure 1 , 2 , 3, 4, 5, 6 and 7 show a roof concentrating photovoltaic power generation device, including a base 1, a control box 3, a solar panel 4 and a convex lens 7, the control box 3 is fixedly installed on the top of the base 1, and the base 1 The top is provided with an angle adjustment component 2;

[0052] The angle adjustment assembly 2 is connected with a protection structure 9 for protection;

[0053] The top of the angle adjustment assembly 2 is provided with a solar panel 4 for power generation;

[0054] The top of the angle adjustment assembly 2 is fixed with supporting plates 5 at equal intervals along the circumferential direction, the top of the supporting plates 5 is connected with a mounting ring 8, the lower end of the inner wall of the mounting ring 8 is provided with a supporting ring 11, and the top of the supporting ring 11 has an outer ring 10 and a convex lens through screws. 7 is installed in the outer ring 10;

[0055]The mountin...

Embodiment 2

[0058] Embodiment 2 is a further improvement to Embodiment 1.

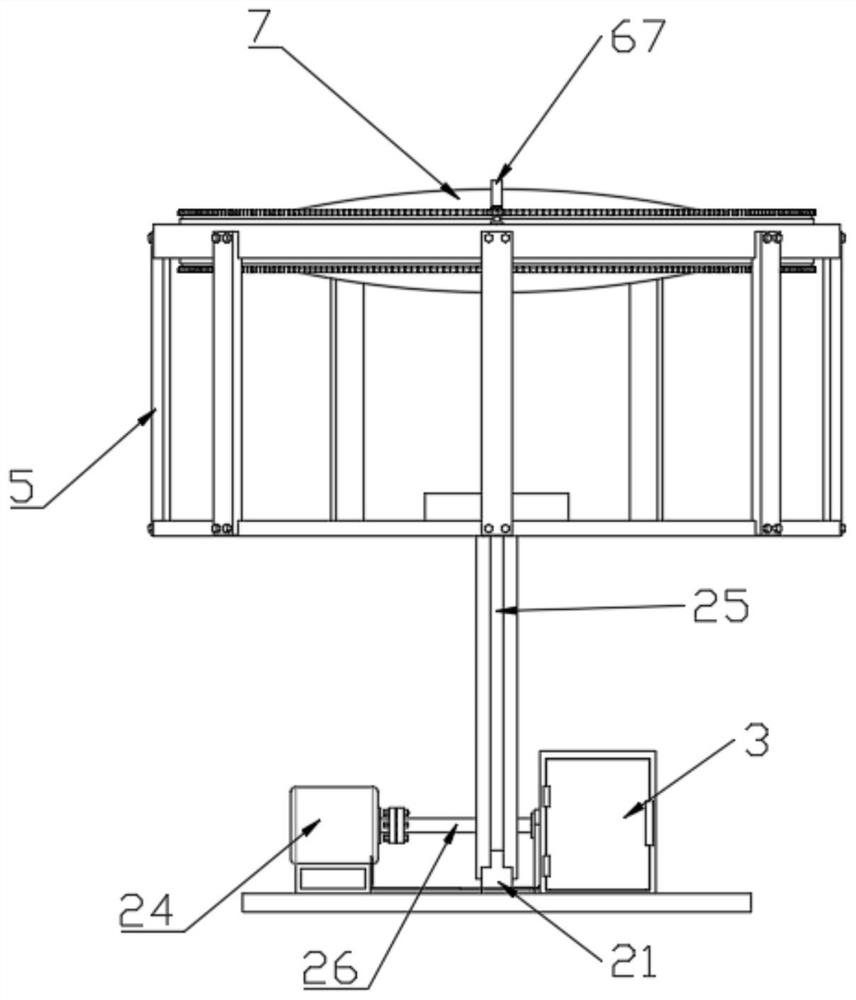

[0059] Such as figure 1 , 2 , 3, 4 and 6 further, the angle adjustment assembly 2 includes an arc-shaped guide rail 21, a semi-circular ring gear 22, a top plate 23, a first drive motor 24, an arc-shaped limit chute 25, a transverse shaft 26 and a first A ring gear 27, the first driving motor 24 is installed on the top of the base 1, the output shaft of the first driving motor 24 is connected to the horizontal shaft 26 through a coupling, the horizontal shaft 26 is equipped with the first ring gear 27, and the arc guide rail 21 is installed on On the top of the base 1, the outer wall of the semi-circular gear 22 is provided with an arc-shaped limit chute 25 used in conjunction with the arc guide rail 21, and the inner wall of the semi-circular gear 22 is meshed with the first gear 27 through a gear block, and the top of the semi-circular gear 22 is provided with There is a top plate 23, a support seat 28 is inst...

Embodiment 3

[0062] Embodiment 3 is a further improvement to Embodiment 2.

[0063] Such as Figure 4 , 5 , the protective structure 9 shown in 6 and 8 comprises installation tube 91, the 7th ring gear 92, spring 93, electromagnet 94, iron sliding plate 95, tooth plate 96 and sliding block 97, and installation tube 91 and electromagnet 94 install On the top of the base 1, the electromagnet 94 is arranged in the installation cylinder 91, the installation cylinder 91 is provided with a spring 93, the top of the spring 93 is provided with an iron sliding plate 95, and the top of the iron sliding plate 95 is fixed with a sliding block 97, and the installation cylinder 91 The top is fitted and slidably connected with the sliding block 97 through a straight hole, the top of the sliding block 97 is fixed with a toothed plate 96, and the top of the toothed plate 96 is meshed with the seventh ring gear 92, and the seventh ring gear 92 is installed at the outer end of the transverse shaft 26. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com