Electrostatic powder spraying process for aluminum profile

A technology for electrostatic powder and aluminum profiles, which is used in liquid spraying equipment, coatings, devices for applying liquid to surfaces, etc., and can solve problems such as uneven spray paint surface and uneven distribution of positive charges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

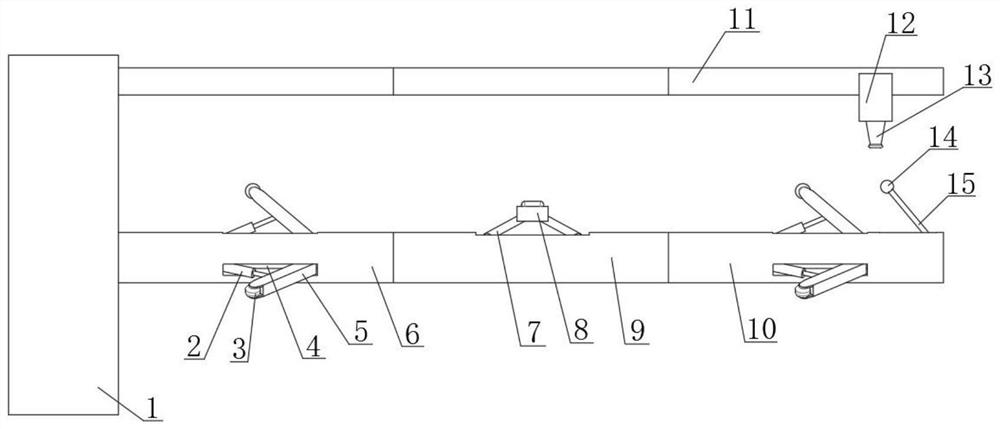

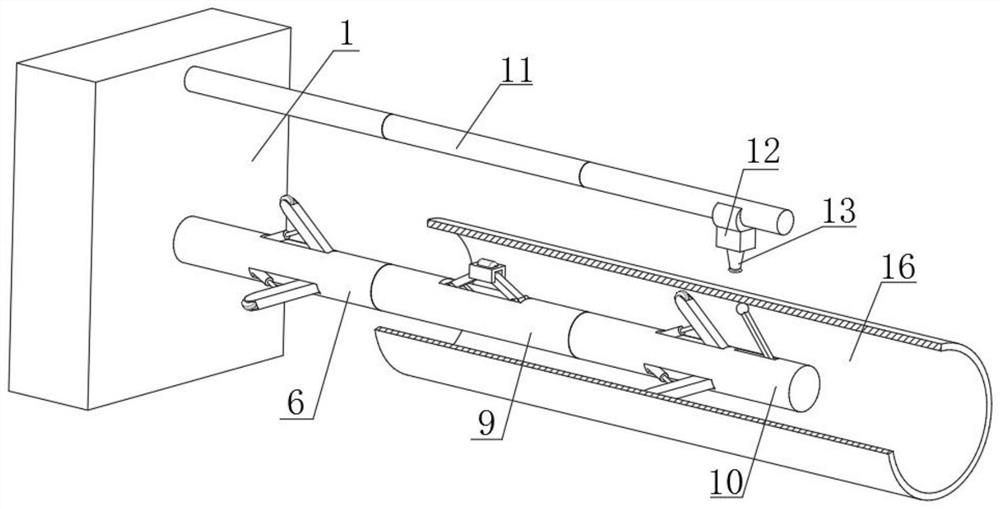

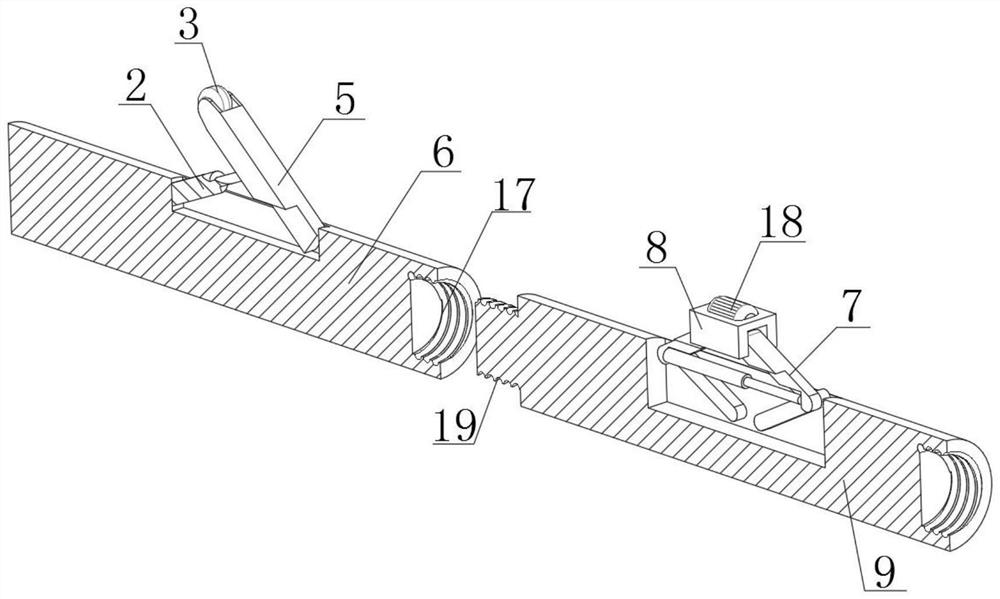

[0031] Refer Figure 1 - Figure 5An aluminum profile electrostatic powder spray process, including suitable positions that secure the fixed base in the workshop before preparing, and assemble the fixed base rod, the power base rod, and the fixed end rod according to the length of the spray aluminum tube, and install it. Suitable order is installed, and the extension rod is held in the top, and the operator puts one end of the aluminum tube at one end of the fixed end rod, and gradually advances, by controlling the first electric push rod and the second electric push rod. However, the top of the support wheel and the drive wheel can be inserted with the peripheral inner wall of the aluminum tube, and the conductive contact ball can be in contact with the inner wall of the aluminum pipe, so that the body of the aluminum tube has a positive charge, during the spraying process, by control For electrical conductivity of the electromagnetic circle, the top magnetic base can be applied to...

Embodiment 2

[0041] Refer Figure 3 - Figure 7 , An aluminum profile electrostatic powder spray process, which is also included in the first embodiment.

[0042] In the present invention, a drying fixed top box 31, which is disposed horizontally disposed, and the bottom of the drying fixed top box 31 is fixed by a bolt, and a dry cylinder 32 disposed at the bottom of the drying fixed top box 31 is fixed by bolt. The bottom of the mouth 13 is fixedly provided with a vertically disposed annular painting holder 33, and the annular painting holder 33 is retained with the horizontal center line of the drying cylinder 32, and the bottom of the top rod 11 is extended to open the slide, and The inner wall sliding card of the chute has a vertically disposed sliding top block 30, and the bottom inner wall of the drying fixed top box 31 is fixedly provided with a horizontally disposed heat-conducting fin 37, and the inner wall of the drying fixed top box 31 is fixed. The horizontally disposed hot compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com