Automatic cleaning tank for semiconductor wafer tank cleaning machine

An automatic cleaning and washing machine technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as unfavorable chemical cleaning liquid reflux temperature control, unfavorable overall linkage and energy saving, rectangular cleaning tank volume Large and other problems, to achieve the effect of reducing the volume, reducing the occupied volume, and increasing the inner area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

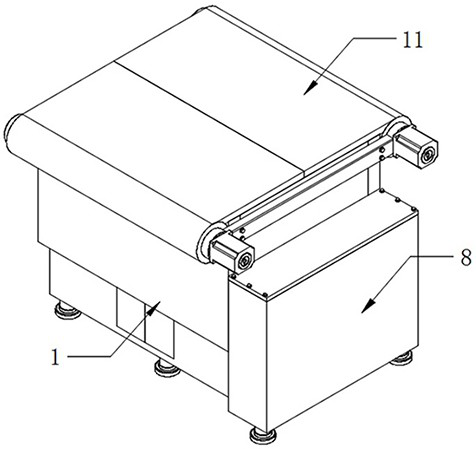

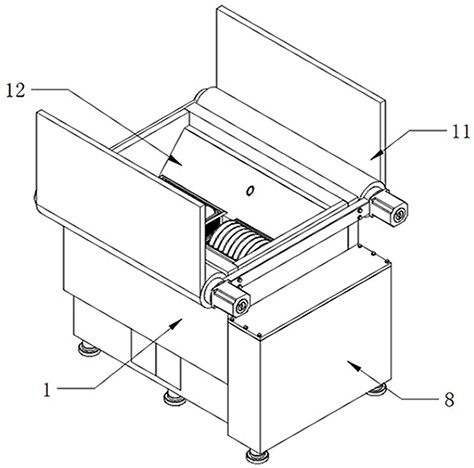

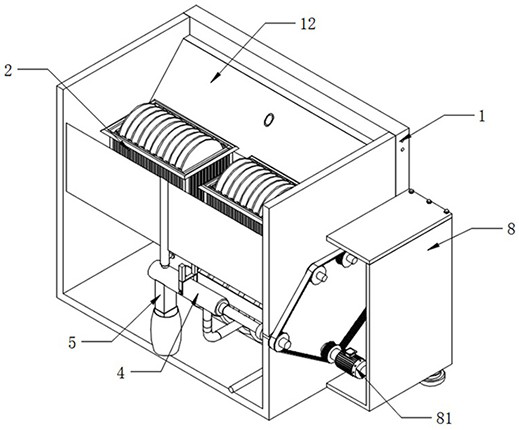

[0050] refer to Figure 1-15 , an automatic cleaning tank for a semiconductor wafer tank cleaning machine, comprising a frame 1, and a groove cover 11 installed on the frame 1, a cleaning tank body 12, a supporting device, a filtering device and a washing device;

[0051] like Figure 1-2 As shown, two slot covers 11 are hingedly arranged on both sides of the top of the frame 1, and a micro motor for driving the hinged slot covers 11 to open and close is arranged in the axial direction thereof, which is convenient for control in the dust-free workshop. Cleaning liquid, especially chemical cleaning liquid, needs to clean the wafer after hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com