Rod piece positioning and bending equipment for comprehensive rod with clamping groove

A slot and rod technology, which is applied in the field of integrated rod and rod positioning and bending equipment with its own slot, can solve the problems of potential safety hazards, low efficiency, low automation level, etc., and achieve fast marking speed and stable bending. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to better understand the solution of the present application, the present application will be further described in detail below in conjunction with the drawings and specific implementation methods. Apparently, the described embodiments are only some of the embodiments of this application, not all of them. Based on the embodiments in this application, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the scope of protection of this application.

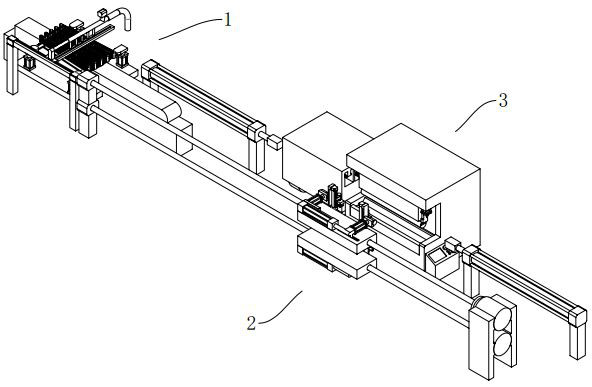

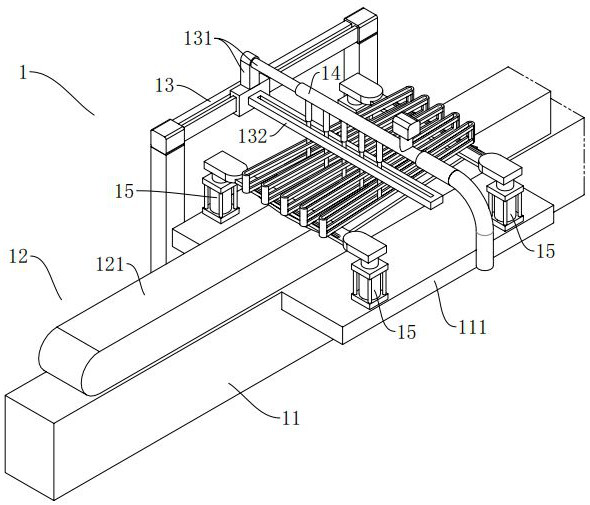

[0039] Such as Figure 1-Figure 15 The shown one kind of self-contained card slot integrated rod positioning and bending equipment includes a marking unit 1 , a transfer unit 2 and a bending unit 3 .

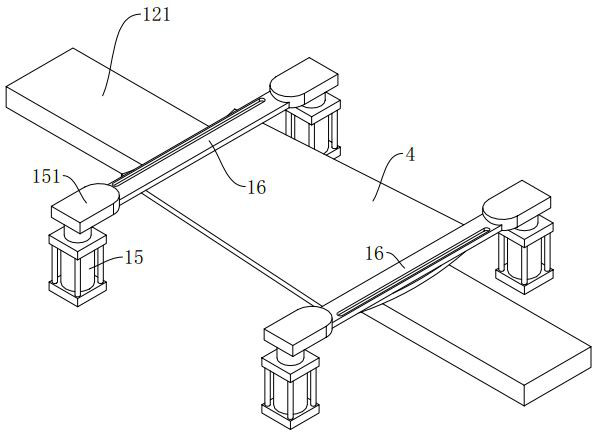

[0040] The scribing unit 1 includes a transmission mechanism, the transmission mechanism includes a platform 11, a pair of convex plates 111 are provided on its two sides, a conveyor 12 is provided on the platform 11, and a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap