Vibration shelling and sand removing device for casting

The technology of a screening device and a movable plate is applied in the field of casting, which can solve the problems of high labor intensity, high noise, and high risk of transportation and placement, and achieve the effects of saving the shelling process and reducing the tendency of cold cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

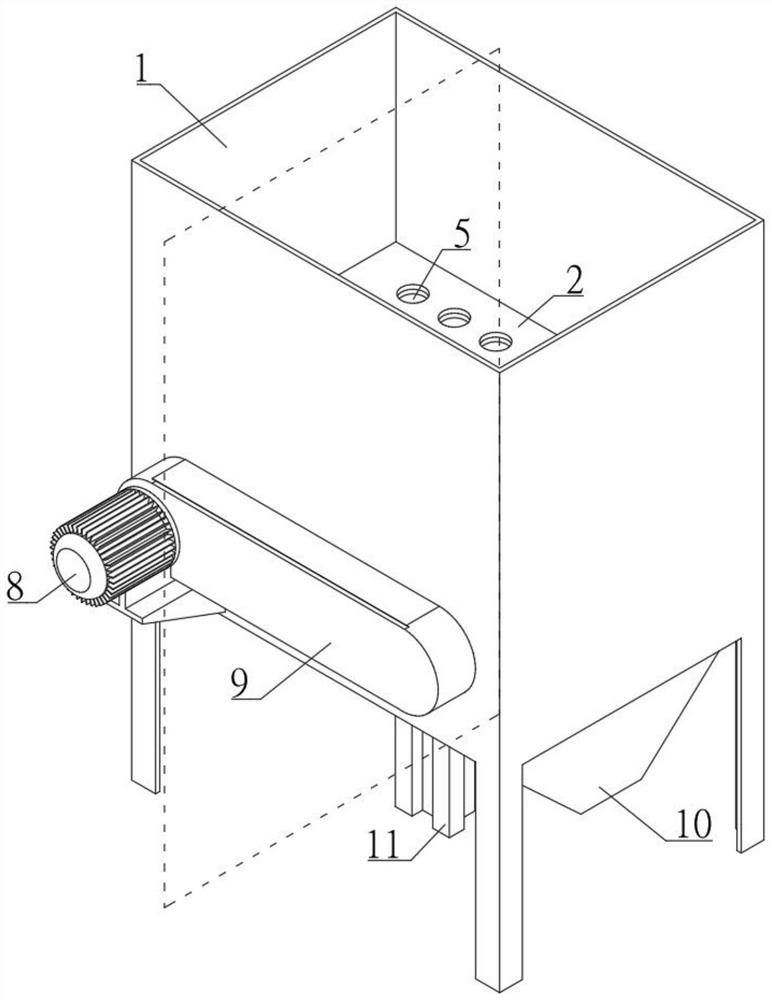

[0032] A casting vibrating dehulling and desanding device includes an outer casing 1 , a collecting box 10 , an upper movable plate 2 , a lower movable plate 4 , a fixed frame 3 and a shelling assembly 6 . The above components are specifically set as follows:

[0033] refer to figure 1 , the outer casing 1 adopts a structure connected up and down, and the outer casing 1 should be made of high temperature resistant materials. In this embodiment, it is a rectangular structure, and a cylindrical structure can also be used.

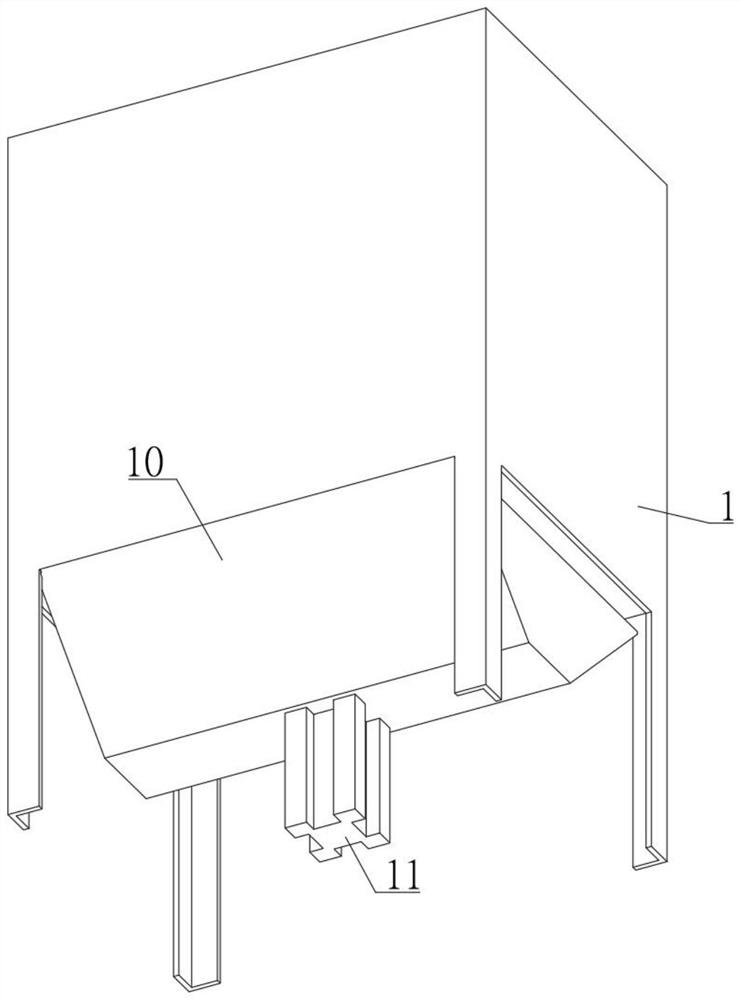

[0034] The collection box 10 is sealed and communicated with the bottom end of the outer casing 1 . A water inlet pipe (not shown) can be installed on the outer shell 1 to add water to the outer shell 1. The collection box 10 is used to collect sandy sewage. sewage.

[0035] There is a gap between the upper movable plate 2 and the lower movable plate 4, and the upper movable plate 2 and the lower movable plate 4 are fixedly connected.

[0036] In this emb...

Embodiment 2

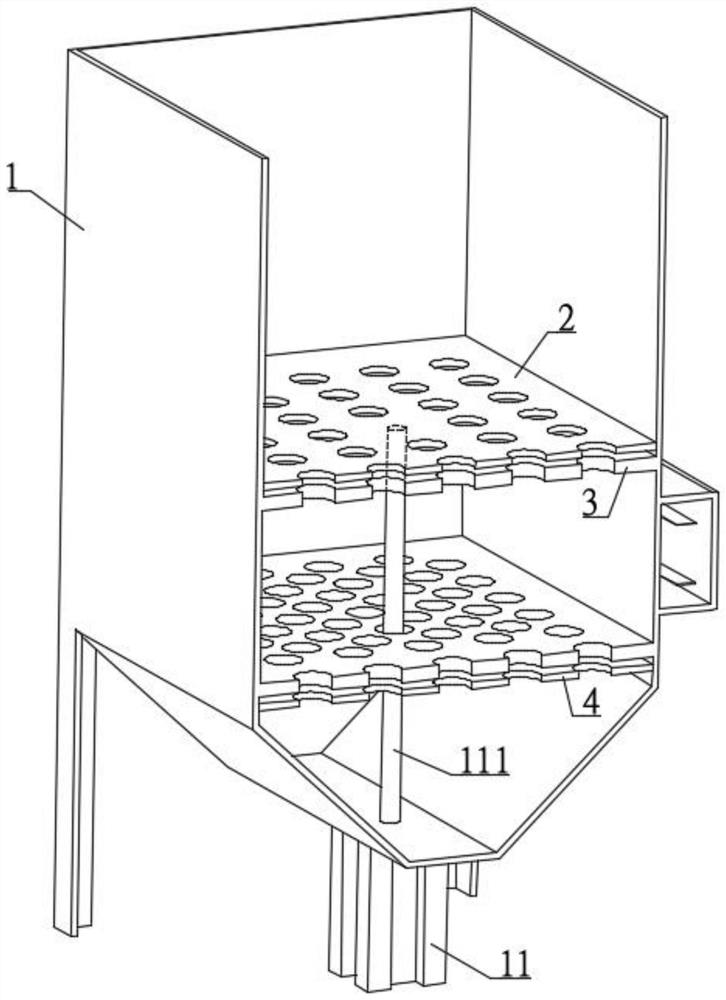

[0054] refer to image 3 The difference between the present embodiment and the first embodiment is that there is a sliding relationship between the upper movable plate 2, the lower movable plate 4 and the housing 1, and also includes the cylinder 11, as follows:

[0055] refer to image 3 , Cylinder 11 is vertically installed on the collection box 10, and the piston rod 111 of cylinder 11 passes through upper movable plate 2, lower movable plate 4 and fixed frame 3, and is fixedly connected with upper movable plate 2 and lower movable plate 4.

[0056]When the cylinder 11 drives the piston rod 111 to move upwards, it drives the upper movable plate 2 and the lower movable plate 4 to move upwards, and the top piece 61 in the shelling assembly 6 cannot be separated from the opening 5 of the lower movable plate 4 when it moves. Specifically, it means that the lower top piece 61 cannot be disengaged from the lower opening 5 during movement, so that the lower movable plate 4 is sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com