Honeycomb core part processing method without adhesive tape bonding

A technology of parts processing and honeycomb core, applied in the field of holding and processing of honeycomb core parts, can solve the problems of easy degumming and pulling, poor holding, high holding cost, and achieve the effect of good holding effect, reducing processing cost and improving holding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

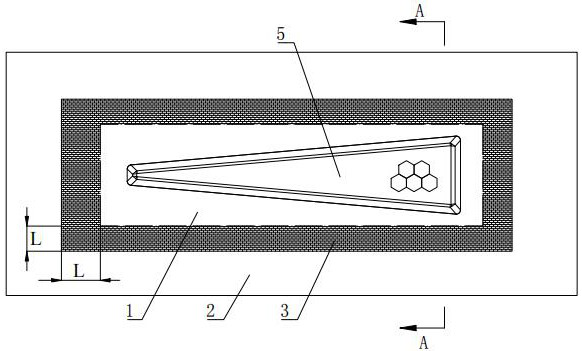

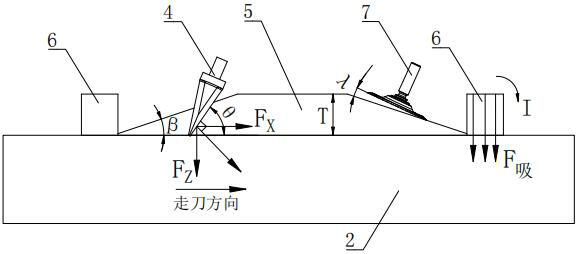

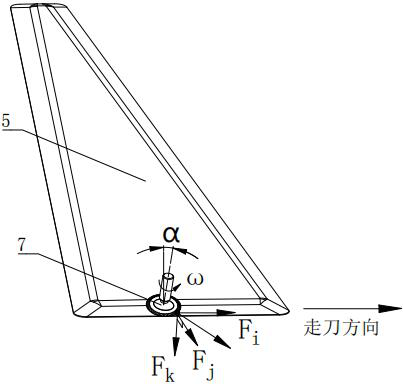

[0041] A method of processing honeycomb core parts without tape bonding, such as Figure 1-Figure 4 As shown, its specific implementation process includes the following steps:

[0042] According to the clamping position of the honeycomb core part blank 1 on the vacuum platform 2 of the ultrasonic machine tool in a free state, the vacuum device is started after covering the surface of the part blank 1 with a layer of polyethylene film 3, so that the part processing area 5 of the part blank 1 and the remaining material The regions 6 and the vacuum platform 2 form a closed cavity to realize the stable holding of the honeycomb core parts.

[0043] The vacuum adsorption force formed by the vacuum holding method is , is the vacuum pressure of the ultrasonic machine tool, Be polyethylene film 3 vacuum adsorption areas; According to the vacuum pressure parameter of existing ultrasonic machine tool, the thickness of the honeycomb core parts processed in the present embodiment T ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com