Intelligent inspection robot for conveyor belt

An intelligent inspection and conveyor technology, which is applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of high cleanliness of the walking track surface, damage to the inspection robot, and damage to the conveyor belt, etc., to achieve The effect of ensuring safety, ensuring stable walking, and avoiding injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

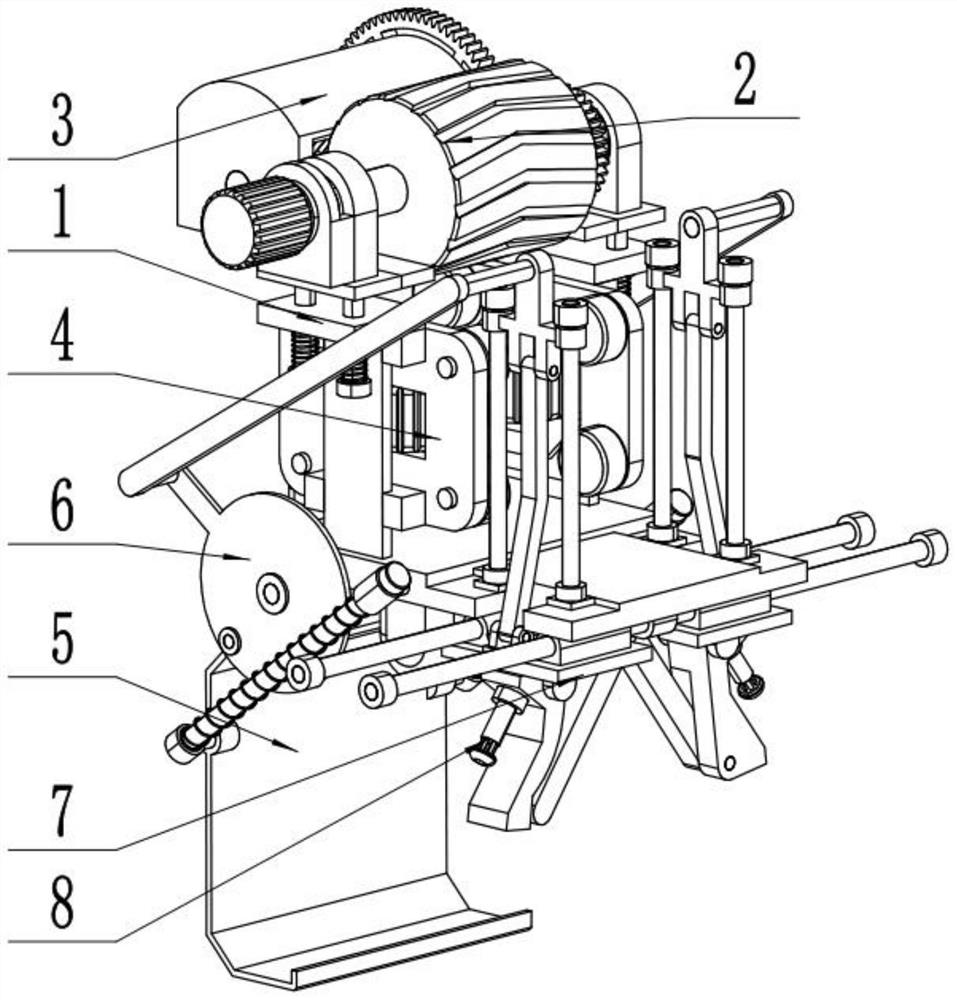

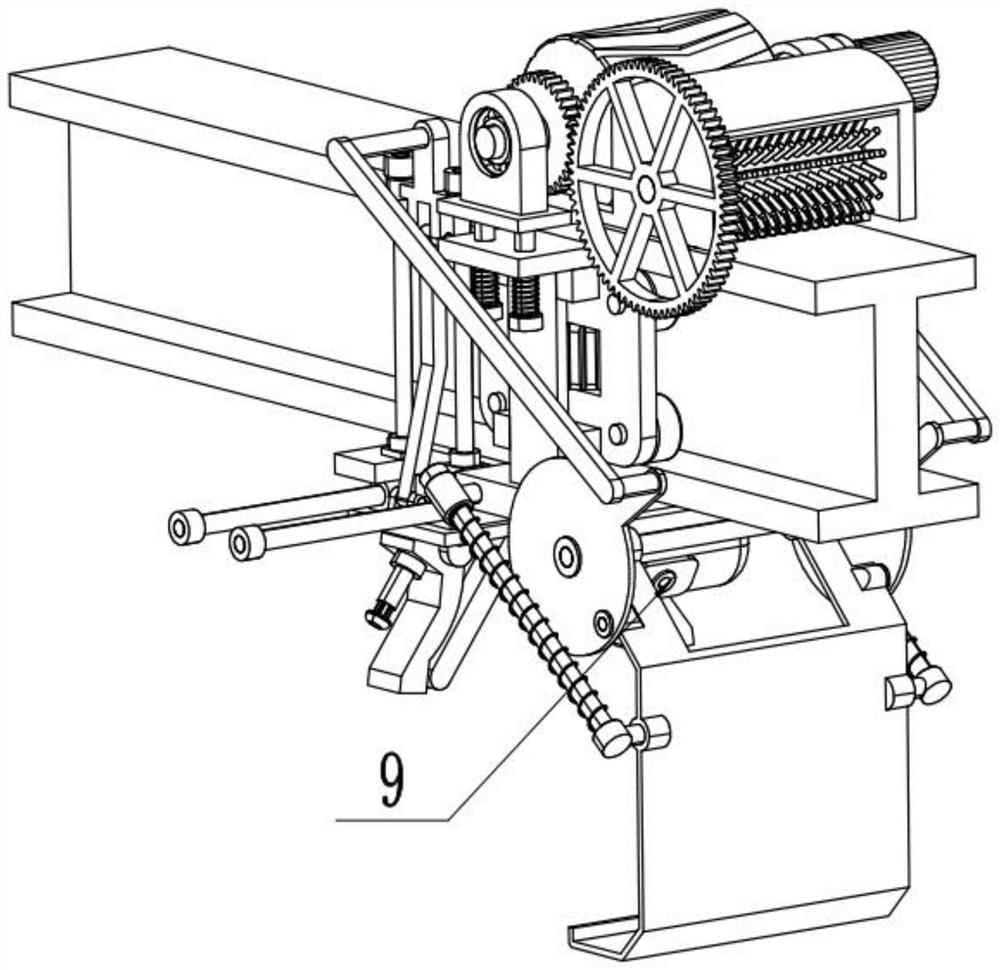

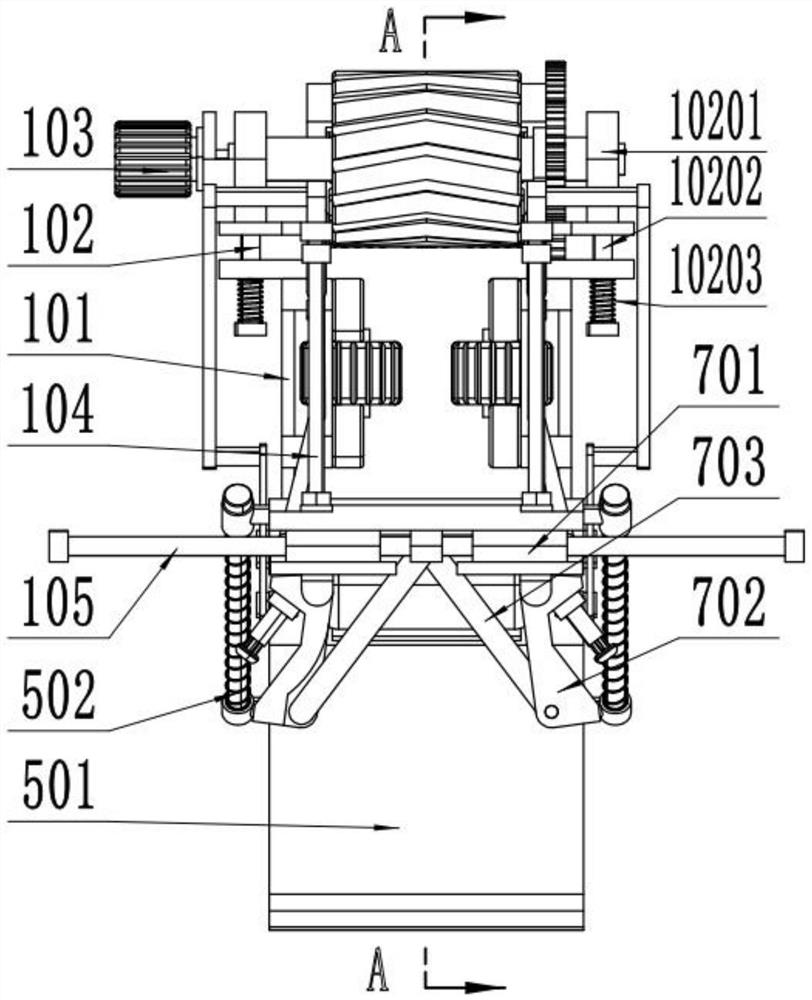

[0022] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 The shown conveyor belt intelligent inspection robot includes a limit mechanism 4, a walking mechanism 2, a main body mechanism 1, and an obstacle avoidance mechanism 5. The main body mechanism 1 includes two parts: a support frame 101 and an adjustment group 102. The limit mechanism 4 is symmetrically and fixedly installed inside the support frame 101, and the limit mechanism 4 is slidably installed on the rail. The adjustment group 102 has two groups. On the adjustment group 102, a casing 106 is provided on the top of the support frame 101, and a cleaning mechanism 3 is installed on the casing 106. When the traveling mechanism 2 rotates, it moves on the rail, and the cleaning mechanism 3 is driven to clean up the dust on the rail; the center position of the bottom of the support frame 101 is A camera 9 is provided, and the obstacle avoidance mechanism 5 is installed at the bottom of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com