Device and method for automatically carrying out optical fiber head falling

An optical fiber and automatic technology, applied in the field of optical fiber manufacturing, can solve problems such as high temperature and low efficiency, and achieve the effects of improving efficiency, smooth movement, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

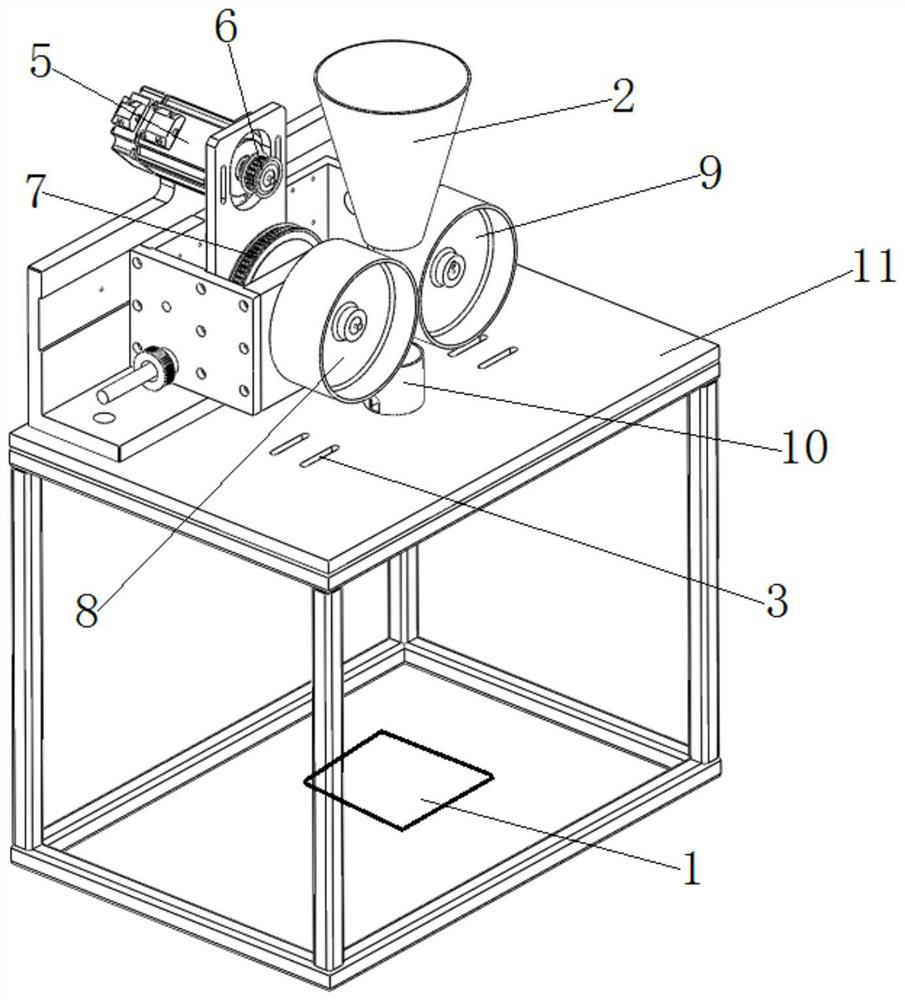

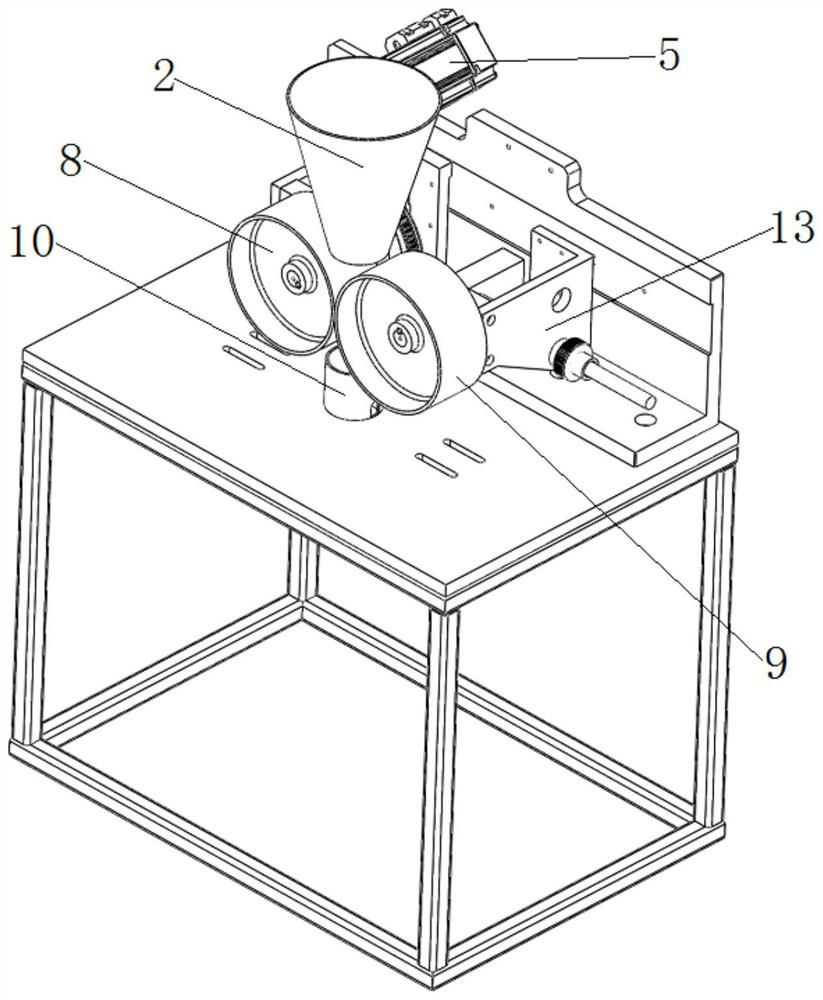

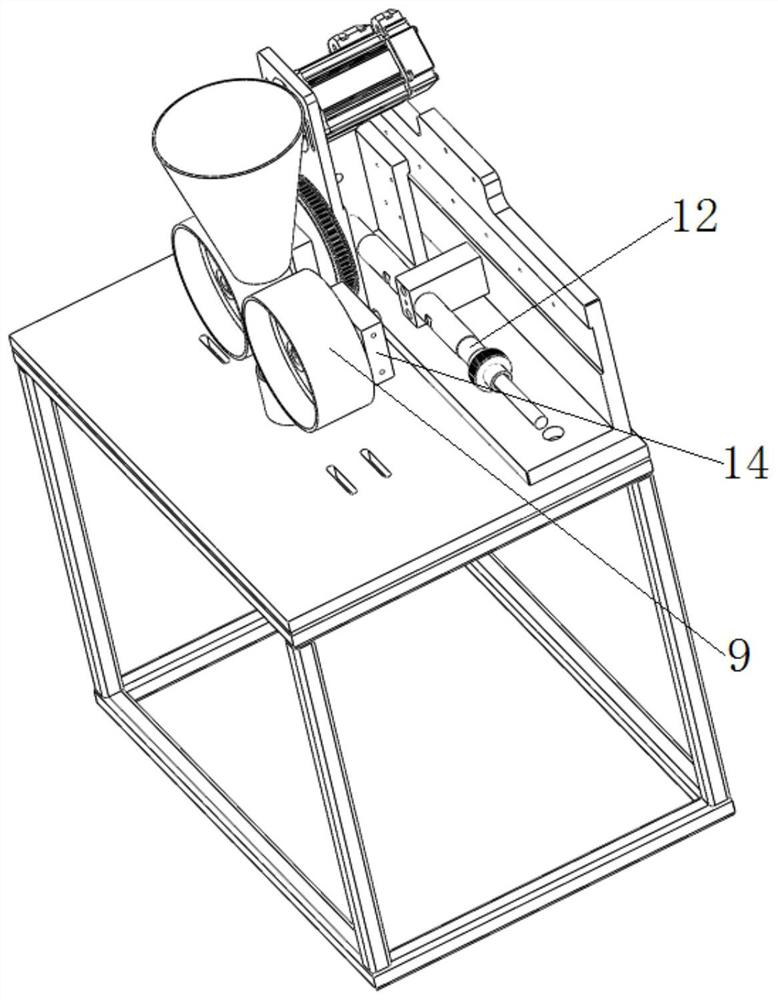

[0033] Such as Figure 1-6 As shown, a device for automatic optical fiber drop, including:

[0034] control module 1;

[0035] The guide groove 2 is used to guide the head of the light rod after melting, so that the head of the light rod after melting falls down into the working area of the cutting cylinder group 3; the guide groove 2 is an inverted circular platform structure, and its diameter is from top to Decrease downward, the opening at the bottom of the guide groove 2 is located above the traction wheel set;

[0036] The sensor module 4 is connected with the control module 1, and is used for sensing whether the head of the light rod falls into the guide groove 2 after melting;

[0037] The servo motor transmission group is connected with the control module 1 and is controlled by the control module 1; the servo motor transmission group includes a servo motor 5, a driving wheel 6 and a transmission wheel 7, and the control module 1 is connected with the servo motor 5,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap