Semi-rigid base material and construction process

A semi-rigid base, cementitious material technology, applied in the direction of coagulation pavement, roads, roads and other directions paved on site, can solve the problem of affecting the overall stability and durability of highways, easy to produce shrinkage cracks and temperature shrinkage cracks, affecting the overall stability and durability of highways. Transportation safety, passenger comfort and other issues, to achieve the effect of reducing maintenance and maintenance costs, reducing cracks, and improving strength and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The present embodiment provides a semi-rigid base material, comprising 100 parts by weight of crushed pebbles, 4.2 parts of crack-resistant silica-alumina-based cementitious material and 5 parts of water.

[0045] (1) Broken pebbles: Broken pebbles are the pebble base materials mined in the river. After cleaning, they are processed into 15mm or more, 10-15mm, 5-10mm, 3- 5 grades of aggregates of 5mm and 0-3mm, the white particle content of the above-mentioned pebble base material is 6%, and the synthetic gradation of broken pebbles is shown in Table 1, and the quality of aggregates of 3 grades above 15mm, 10-15mm, and 5-10mm The test results are shown in Table 2, and the quality of the test results for the 2-grade aggregates of 3-5mm and 0-3mm are shown in Table 3.

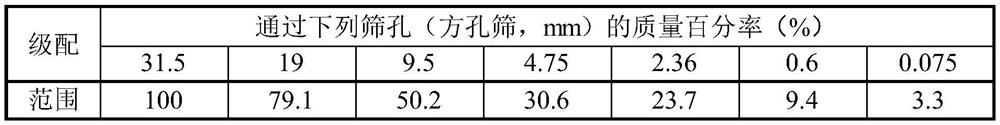

[0046] Table 1 Synthetic gradation of the broken pebbles of Example 1

[0047]

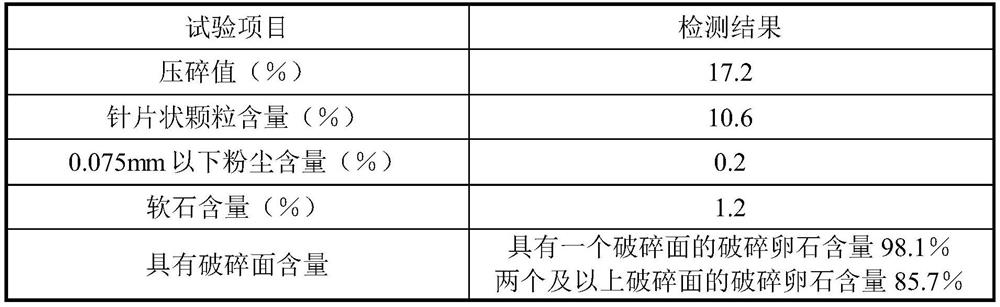

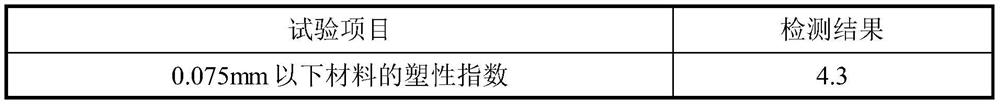

[0048] Table 2 The quality test results of 3 grades of aggregates above 15mm, 10-15mm, and 5-10mm in Example 1

[0049] ...

Embodiment 2

[0060] The present embodiment provides a semi-rigid base material, comprising 100 parts by weight of crushed pebbles, 4.2 parts of crack-resistant silica-alumina-based cementitious material and 5 parts of water.

[0061] (1) Broken pebbles: Broken pebbles are the pebble base materials mined in the river. After cleaning, they are processed into 15mm or more, 10-15mm, 5-10mm, 3- 5-grade aggregates of 5mm and 0-3mm, the white particle content of the above-mentioned pebble base material is 7%, and the synthetic gradation of broken pebbles meets the requirements of Table 4, and the 3-grade aggregates of 15mm or more, 10-15mm, and 5-10mm meet the requirements of Table 4. Table 5 requirements, 3-5mm and 0-3mm grade 2 aggregates meet the requirements of Table 6.

[0062] The synthetic gradation of the broken pebble of table 4 embodiment 2

[0063]

[0064] Table 5 Quality requirements for aggregates of 15mm above, 10-15mm, and 5-10mm in Example 2

[0065]

[0066] Table 6 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com