Synthesis method of vulcanization accelerator 2-(morpholinyl thio) benzothiazole

A technology of benzothiazole and morpholine sulfur is applied in the synthesis field of vulcanization accelerator 2-benzothiazole, can solve the problems of low yield, use of chemical dose oxidant, etc., achieves fast reaction speed, reduces waste water discharge, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

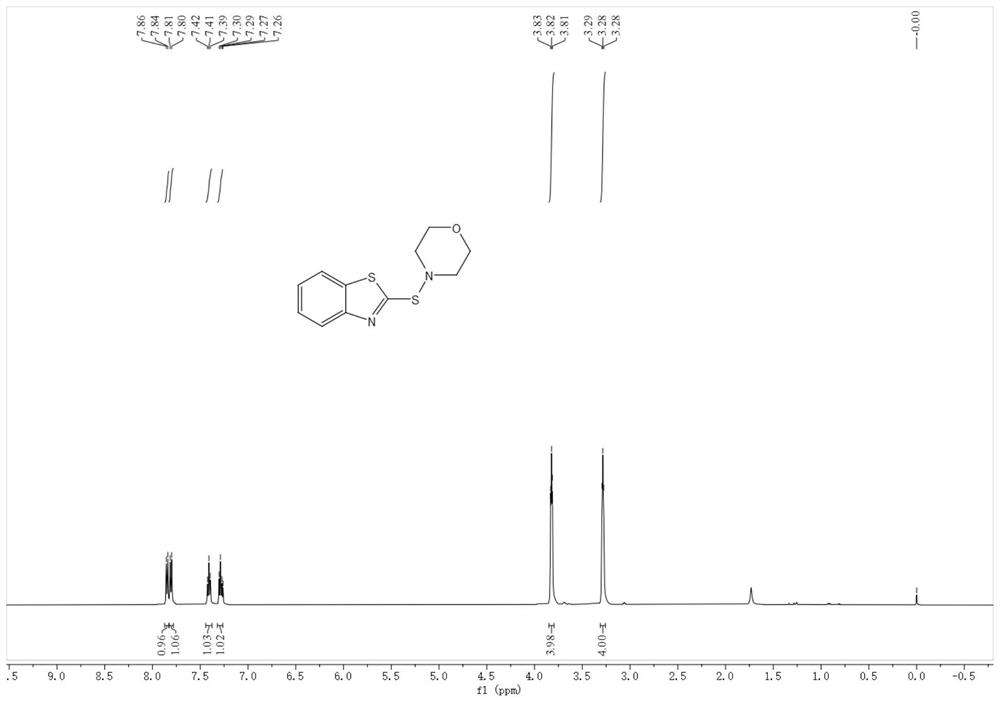

Image

Examples

Example Embodiment

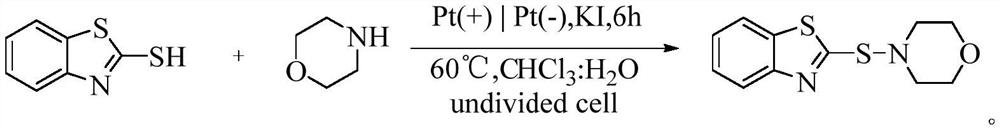

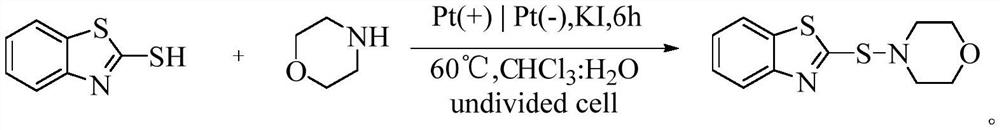

[0026] The present invention provides a synthetic method of 2- (morpholinylthio) benzothiazole, including the following steps:

[0027] (1) 2-mercaptophenyl thiazole, morpholine, electrolyte mixed with chloroform and water mixed with chloroform and water to obtain a mixed liquid, and the platinum sheet is an electrolyte material, and the energization reaction is carried out to obtain a reaction mixture;

[0028] (2) After the reaction mixture obtained by step (1), 2- (morpholinthylthio) benzothiazole was processed.

[0029] In one embodiment of the invention, in step (1), the electrolyte is potassium iodide.

[0030] In one embodiment of the invention, in step (1), 2-mercaptophenyltothiazole, morpholine, electrolyte, and mixed solvents of chloroform and water mixed solvents are 0.5 mmol: 1.0 mmol: 0.25 mmol: 3 ml.

[0031] In one embodiment of the invention, in step (1), in the mixed solvent of chloroform and water, the volume ratio of chloroform and water is 1: 1.

[0032] In one...

Example Embodiment

[0043] Example 1

[0044] This embodiment provides a 2- (morpholinylthio) benzothiazole and its electrochemical synthesis method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com