Barrier coating, preparation method thereof and method for coating barrier coating

A technology for coatings and rubber products, applied in the field of materials, can solve the problems of difficulty and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the above-mentioned barrier coating provided by the present invention comprises the following steps: under an inert atmosphere, mixing the isocyanate component, the first auxiliary agent, and the first solvent according to the mass ratio of 100:(0-100):(0-100) , to obtain component A; under an inert atmosphere, mix the amino compound, defoamer, aluminum powder, second additive, and second solvent in a mass ratio of 100: (0.5~1): (2~7): (0 ~31): (100~131) mixed to obtain component B; mix component A and component B at a mass ratio of 1~1.5:1 to obtain a barrier coating.

[0043] Specifically, under an inert atmosphere, the process of mixing the isocyanate component, the first additive, and the first solvent according to the mass ratio of 100:(0-100):(0-100) includes: pumping the first mixing device to a vacuum , pass inert gas to replace the gas in the first mixing device, and at the same time make the first mixing device in an inert atmosphere ...

Embodiment 1

[0057] Preparation of Barrier Coatings

[0058] Preparation of component A: MDI-50 and polyoxypropylene glycol (PPG) are mixed according to a mass ratio of 104:100 to form component A, wherein MDI-50 is MDI-50 produced by Wanhua Company. The isocyanate group content of MDI-50 is 33.6%, and the isocyanate group content in A component is 15%, wherein the molecular weight of polyoxypropylene glycol (PPG) is 2000, and the hydroxyl value is 56;

[0059]Preparation of component B: Mix polyaspartic acid, amino-terminated polyether, defoamer, aluminum powder, and butyl acetate in a mass ratio of 200:62:1:5:262 to form component B, wherein Polyaspartic acid is Desmophen-NH-1220 resin produced by Covestro, with an amine equivalent weight of 234; amino-terminated polyether is D2000 produced by Huntsman, and the defoamer is 065 produced by BYK Model, aluminum powder is flaky aluminum powder using wet ball milling, and the average particle size is 6μm;

[0060] Transport component A and ...

Embodiment 2

[0062] Preparation of Barrier Coatings

[0063] Preparation of component A: Mix HDI trimer and butyl acetate in a mass ratio of 100:100 to form component A; the HDI trimer is the N3390 model produced by Covestro, and the isocyanate in the HDI trimer The mass ratio of is 19.6±0.3%;

[0064] Preparation of component B: Mix polyaspartic acid, defoamer, aluminum powder, and butyl acetate in a mass ratio of 73:0.5:5:73 to form component B, in which polyaspartic acid is produced The F420 resin from Feiyang Company has an amine equivalent of 277; the defoamer is the 066N model produced by BYK Company, and the aluminum powder is flaky aluminum powder using wet ball milling, and the average particle size is 8 μm;

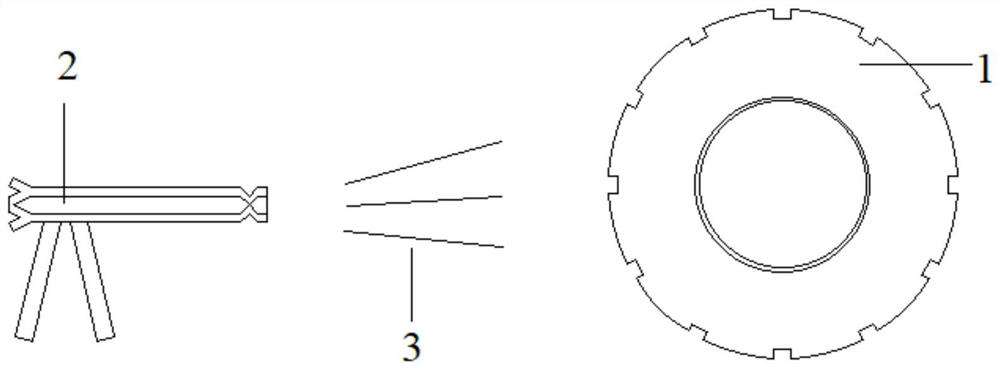

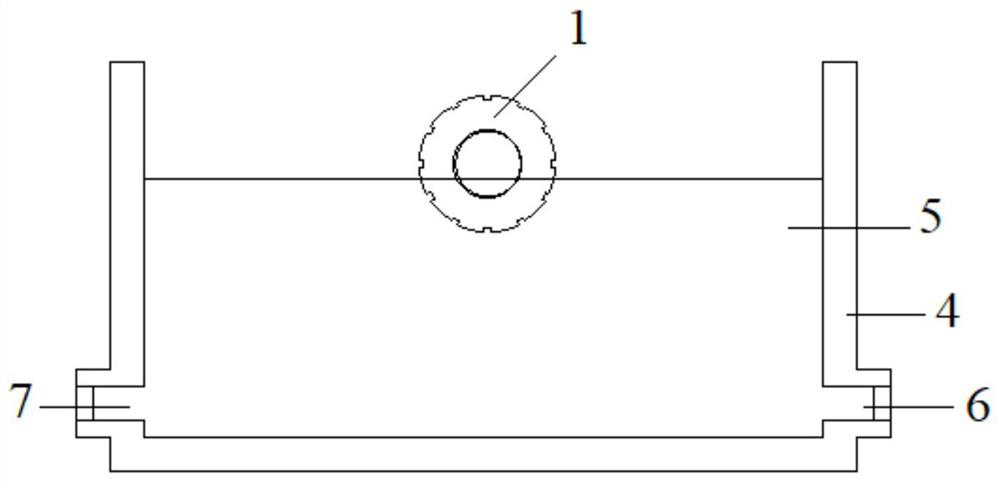

[0065] Send component A and component B according to the mass ratio of 1:1 to such as figure 2 Roller tank mixing shown, the barrier coating is applied to the tire surface by rolling the tire.

[0066] The odor level of the tire was tested with reference to the Geely ass...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap