Marine hydrate exploitation and reinjection system and method

A hydrate and marine technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve problems such as low energy efficiency, and achieve the effects of increasing gas production, promoting decomposition, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: A production well and a reinjection well form a production reinjection well group

[0038] Embodiment 1 provides a marine hydrate exploitation and reinjection system, the structure of which will be described in detail below with reference to the accompanying drawings.

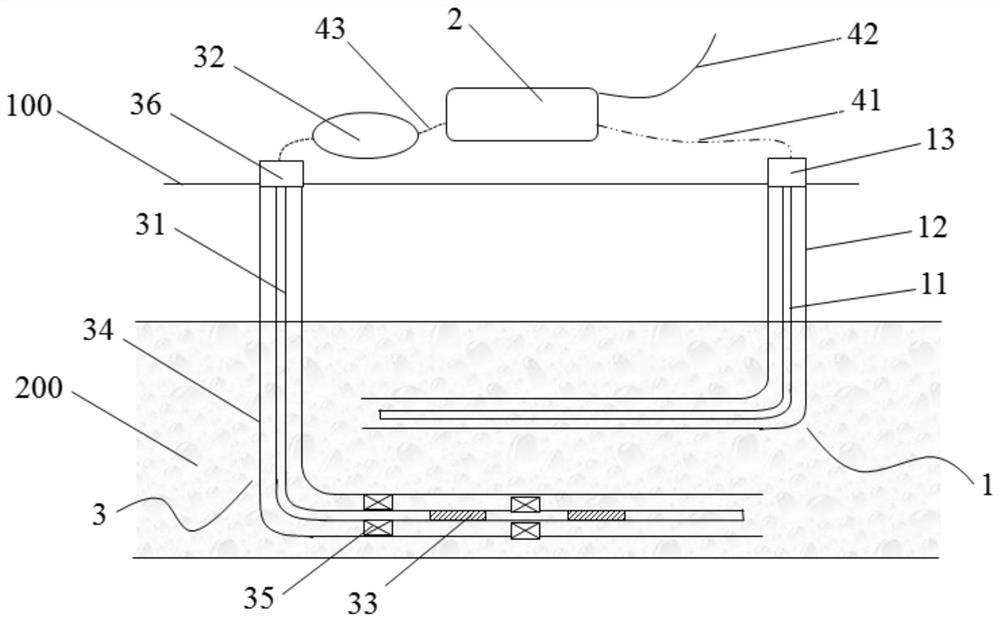

[0039] refer to figure 1 , the marine hydrate production and reinjection system includes a production reinjection well group 6, a gas-liquid separator 2, a subsea production pipe 41, a natural gas delivery pipe 42 and a subsea reinjection pipe 43, each production reinjection well group 6 Including a production well 1 and a reinjection well 3,

[0040] Wherein, the production well 1 and the reinjection well 3 are both arranged in the natural gas hydrate reservoir 200 on the seabed, and the gas-liquid separator 2 is arranged on the seabed near the production well 1 and the reinjection well 3;

[0041]The gas-liquid separator 2 is provided with a gas-liquid mixture inlet, a gas outlet and a ...

Embodiment 2

[0053] Embodiment 2: Marine hydrate production and reinjection method based on the structure of Embodiment 1

[0054] Embodiment 2 provides a method of marine hydrate exploitation and reinjection, using the marine hydrate exploitation and reinjection system provided in Embodiment 1, the method includes the following steps:

[0055] The production well 1 exploits the marine hydrate in the natural gas hydrate reservoir 200, and the marine hydrate decomposes to produce gas-liquid mixed fluid;

[0056] The gas-liquid mixed fluid flows through the production pipe 11 to the wellhead 13 of the production well, flows out from the wellhead 13 of the production well into the subsea production pipe 41, and enters the gas-liquid mixture inlet of the gas-liquid separator 2 through the subsea production pipe 41;

[0057] The gas-liquid separator 2 separates the gas-liquid mixed fluid into gas and liquid;

[0058] The separated gas flows out from the gas outlet of the gas-liquid separator 2...

Embodiment 3

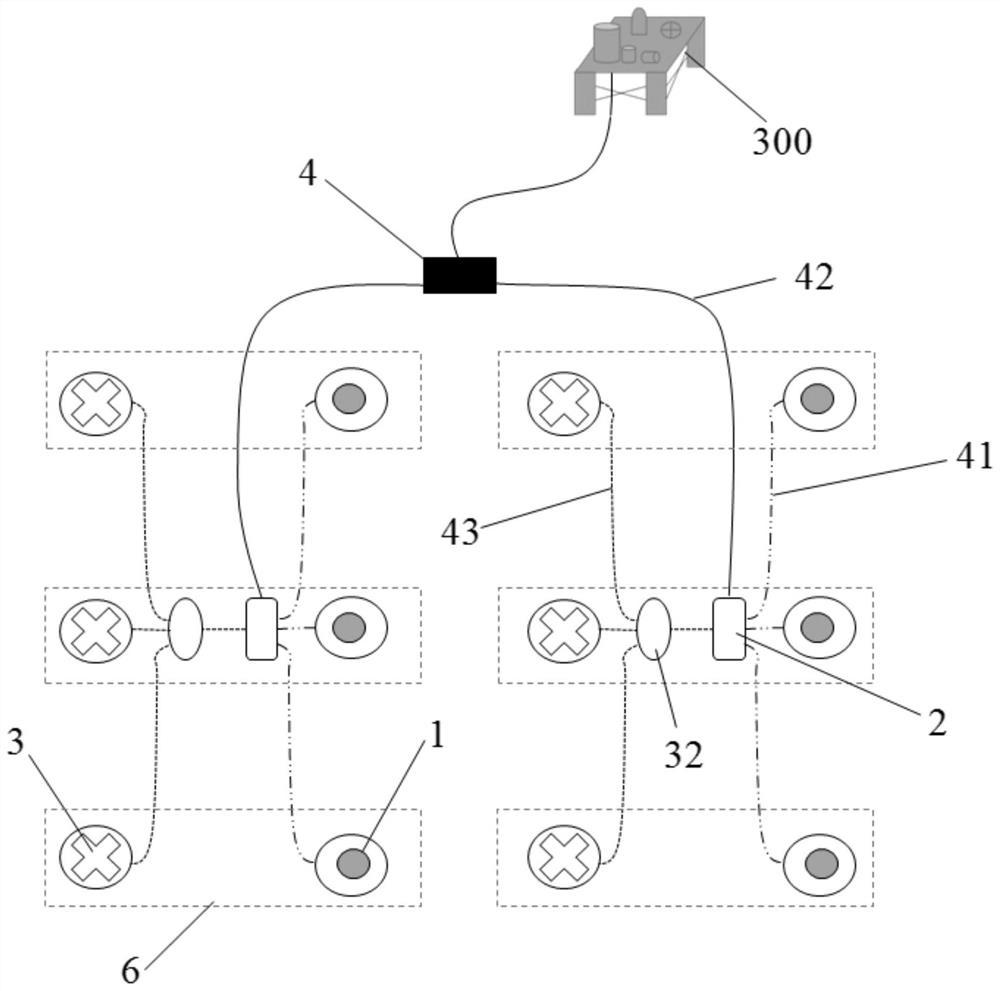

[0060] Example 3: Four production wells and one reinjection well form a five-point well pattern for production and reinjection

[0061] Embodiment 3 provides a marine hydrate production and reinjection system, which is improved on the basis of the production and reinjection well group 6 provided in Embodiment 1. The improvement is as follows:

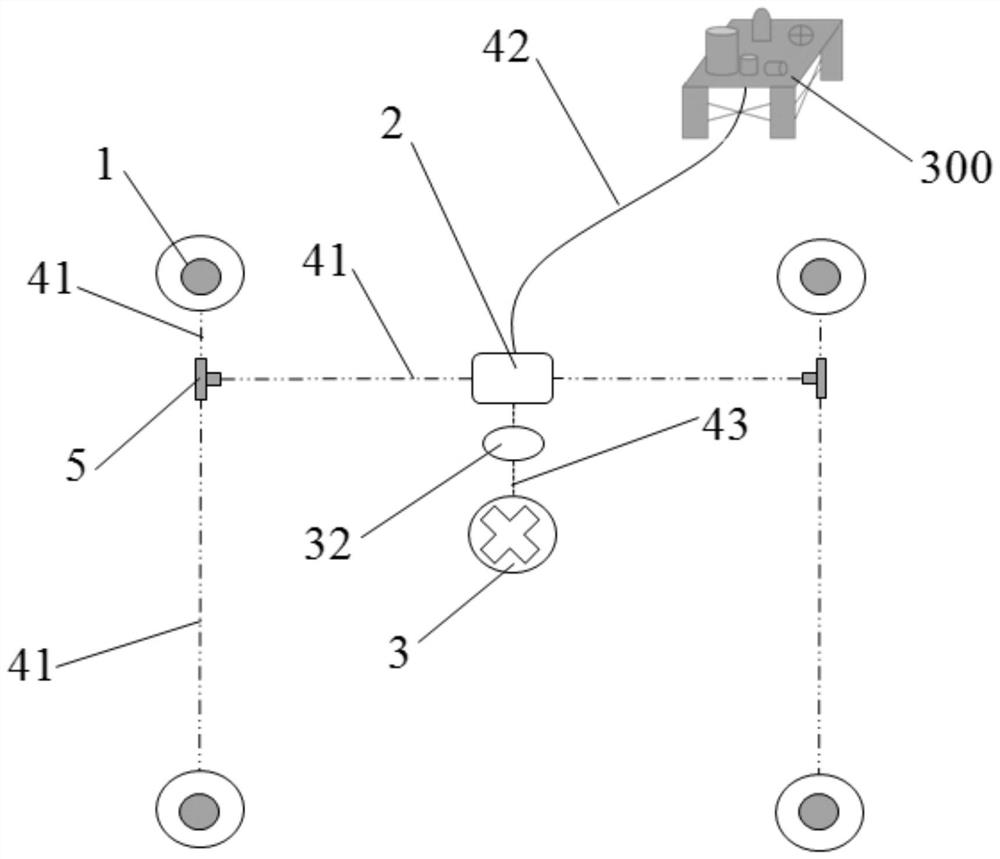

[0062] refer to figure 2 , the marine hydrate production and reinjection system includes four production wells 1 and one reinjection well 3,

[0063] The four production wells 1 present a distribution of four vertices of a rectangle on the seabed, and the horizontal section of each production well 1 is set in the natural gas hydrate reservoir 200;

[0064] A reinjection well 3 is set at the center of a rectangle formed by connecting four production wells 1 end to end, and the horizontal section of the reinjection well 3 is set in the natural gas hydrate reservoir 200 and is located below the horizontal section of the production well 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com