Vertical shaft grouting curtain design and grouting process under deep asymmetric stress condition

A grouting curtain, asymmetric technology, applied in vertical shaft equipment, computer-aided design, design optimization/simulation, etc., can solve the problem of not meeting the needs of water control in the wellbore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

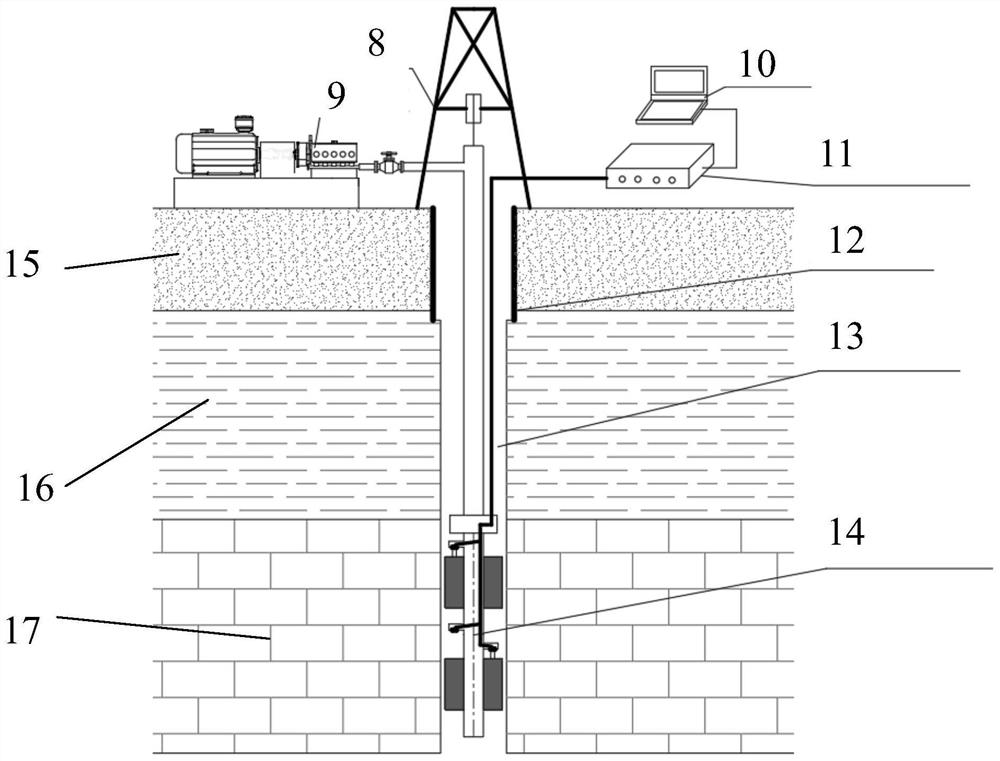

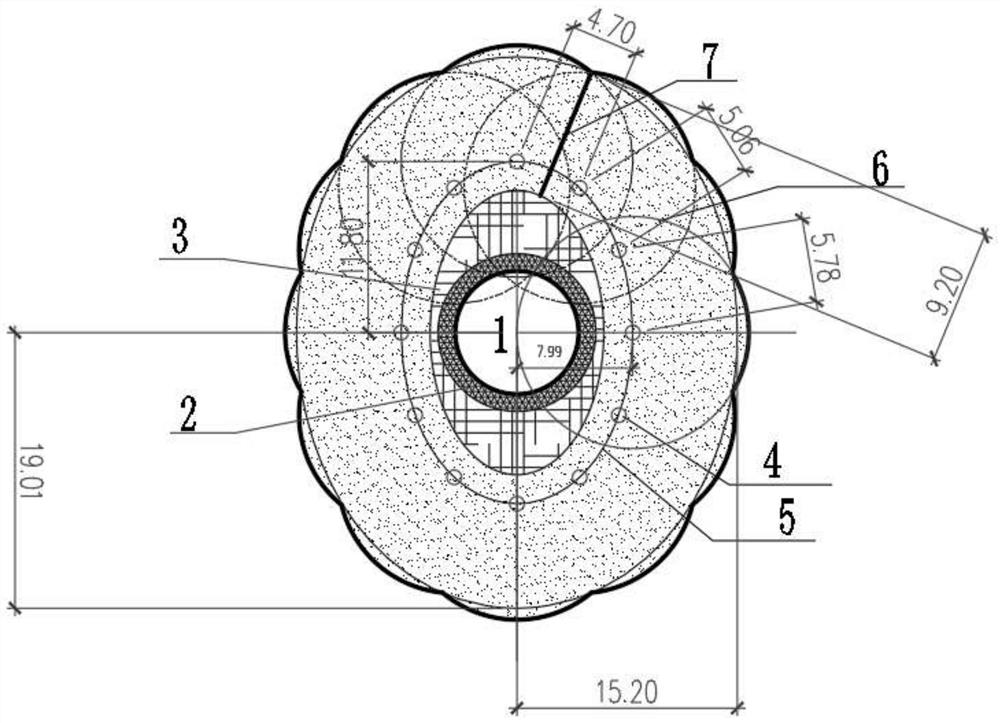

[0052] Under the condition of asymmetric stress in this embodiment, the ground pre-grouting project of a deep shaft in a western mine

[0053] Basic conditions of the project: shaft shaft 1 has an excavation diameter of 8.5m, and the buried depth ranges from 500 to 800m to contain multiple layers of aquifers. Since the project is located in a mountainous area, the tectonic movement is strong, and the surrounding in-situ stress test results show that the in-situ stress field in this area presents an asymmetrical form.

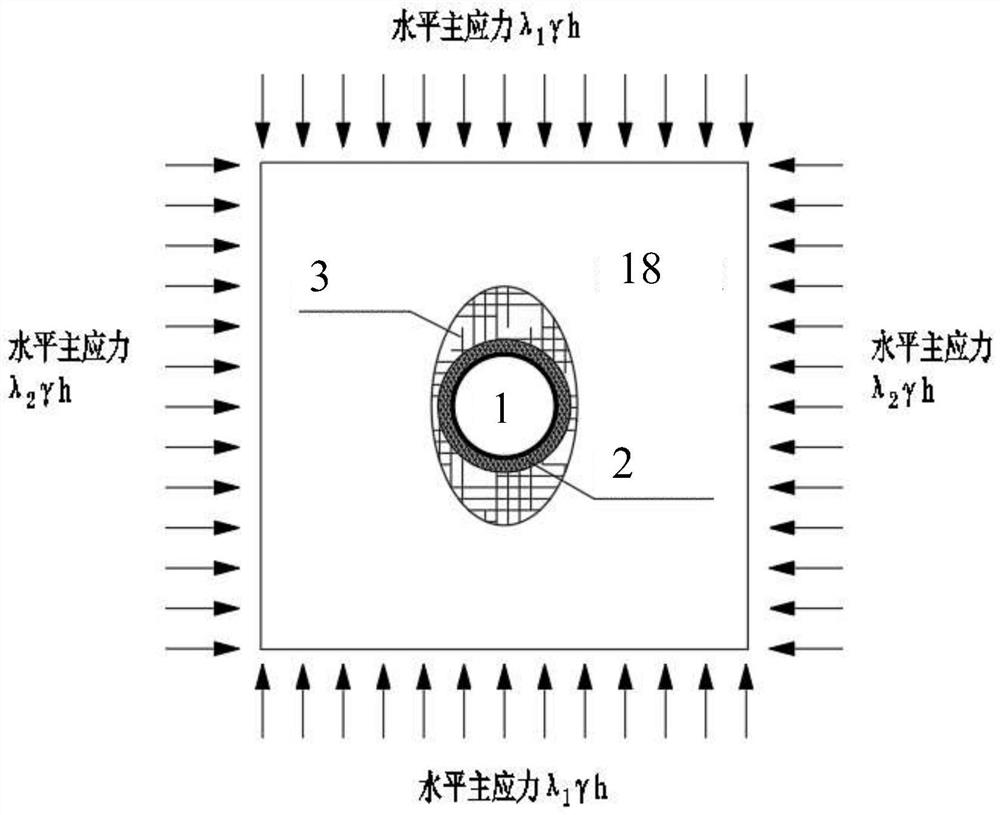

[0054] A: Using in-situ stress testing and numerical simulation analysis, the asymmetric stress distribution in the deep is obtained by inversion.

[0055] (A-1) Use the on-site wellbore inspection hole to carry out deep asymmetric ground stress testing to obtain the ground stress magnitude and direction of the deep bedrock aquifer, including the horizontal maximum principal stress value, horizontal minimum principal stress magnitude and direction;

[0056] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com