Large-span column-free underground tunnel structure and method based on advanced pilot tunnels and opposite-pulling anchor cables

A technology for pulling anchor cables and tunnels, applied to underground chambers, tunnels, tunnel linings, etc., can solve problems such as the inability to provide reference and guidance for this, and the inability to realize the requirements for large-span and column-free space use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

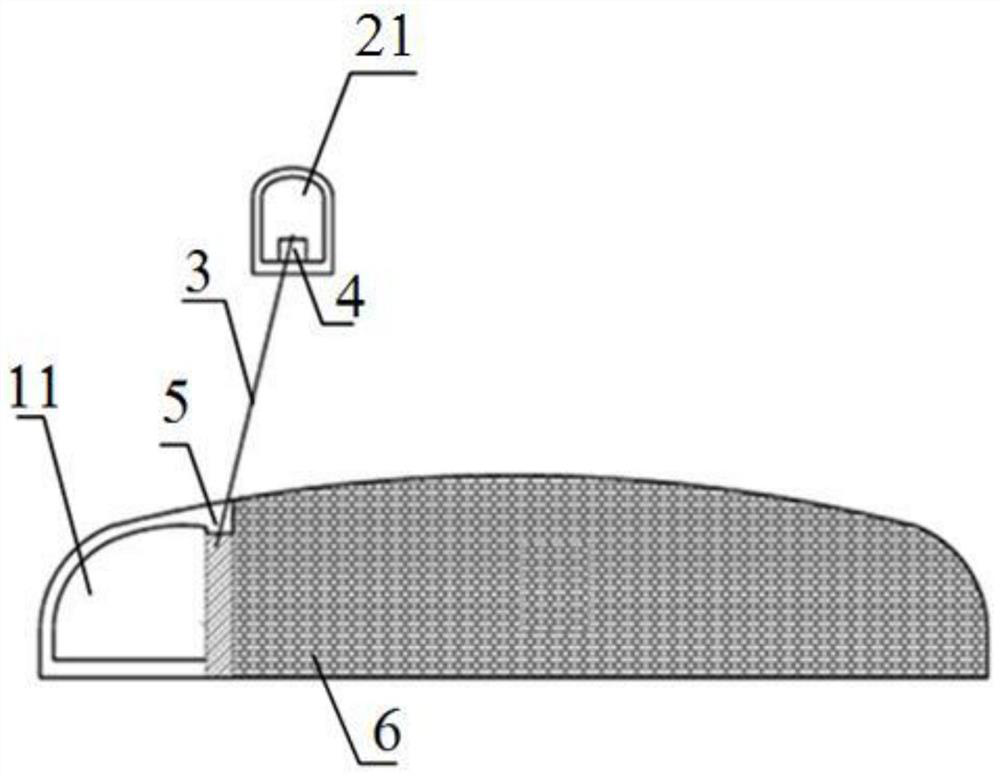

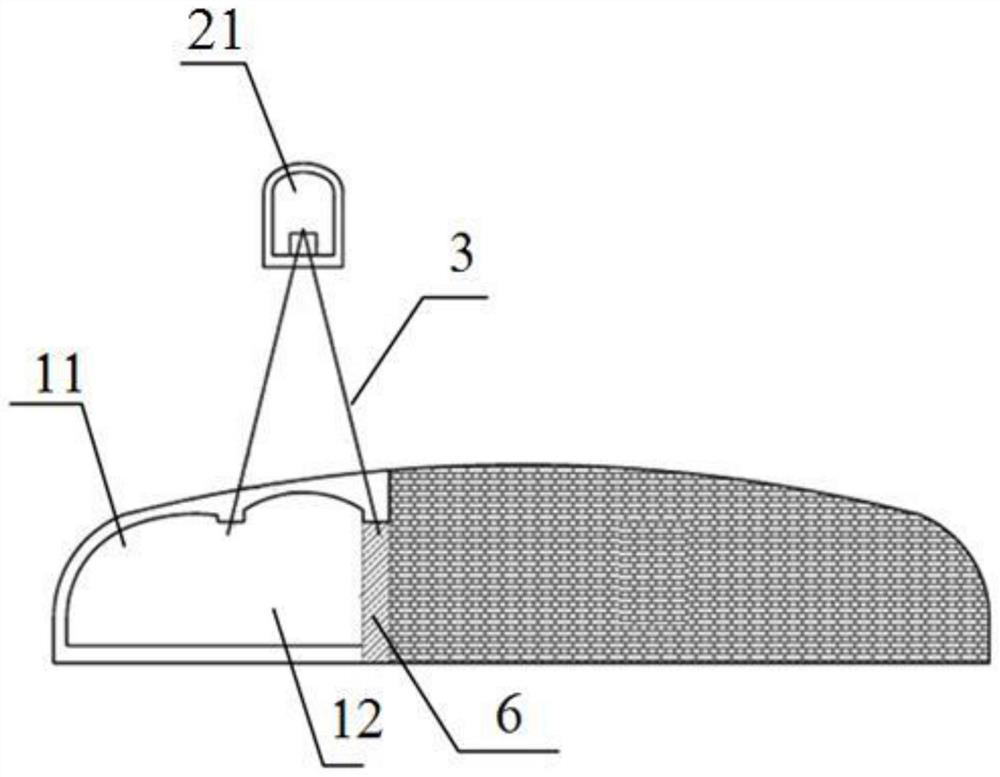

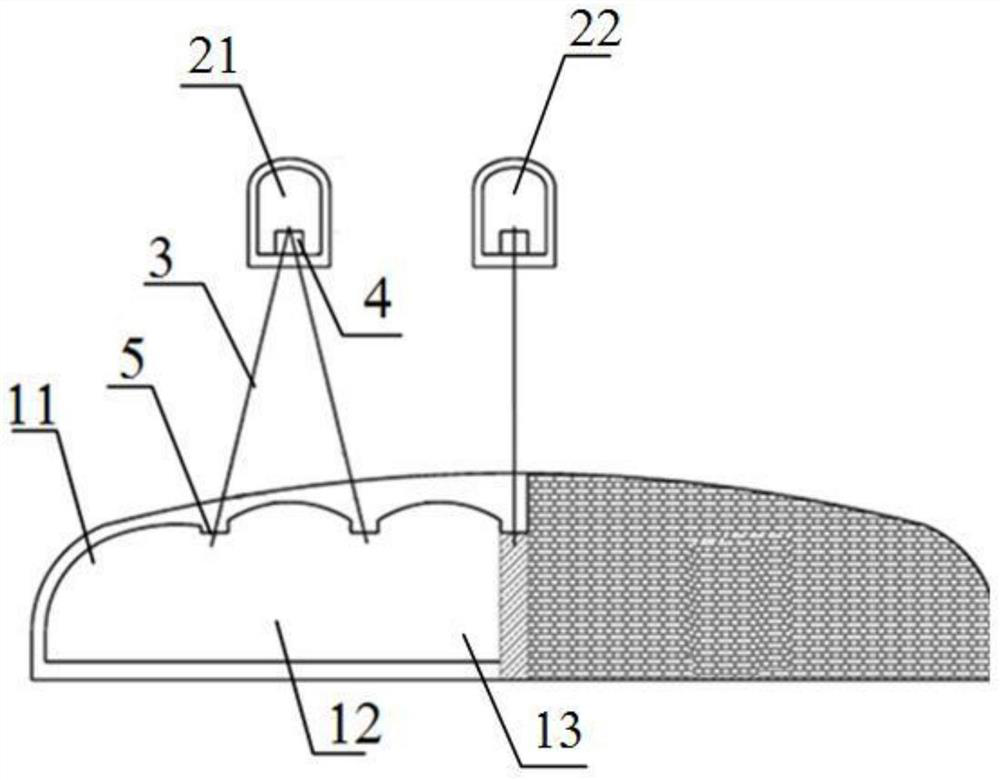

[0025] Embodiment 1: as Image 6 , Figure 7 As shown, a large-span column-free underground tunnel structure based on advanced pilot tunnels and opposite pull anchor cables, including underground tunnels 1, several advanced pilot tunnels, and several opposite pull anchor cables 3; wherein: the section of the underground tunnel 1 is Multi-arch form; the leading pilot tunnels respectively extend along the longitudinal axis of the underground tunnel, and several of the leading pilot tunnels are arranged horizontally side by side above the roof of the underground tunnel 1; the leading pilot tunnels respectively pass through several The anchor cable 3 is connected with at least one adjacent span intersection in the multi-arch structure of the underground tunnel 1 .

[0026] Specifically, such as Image 6 As shown, in the long-span column-free underground tunnel structure described in Example 1, in order to avoid the surrounding rock disturbance during the excavation process as mu...

Embodiment 2

[0028] Embodiment 2: as Figures 6 to 7 As shown, a large-span column-free underground tunnel structure based on advanced pilot tunnels and paired anchor cables differs from Embodiment 1 in that as a preference, among several paired anchor cables 3 connected to each advanced pilot tunnel, The distance between each group of paired anchor cables arranged at equal intervals in the longitudinal direction is set to 4-8m; according to the span of the single hole and the stratum conditions, in each group of paired anchor cables, the length of the anchor rod is set to 15-35m, and the preload is 1000kN~2000kN.

[0029] The formation conditions applicable to the large-span column-free underground tunnel structure described in Embodiments 1 and 2 of the present invention are: II-IV hard rock formations with static lateral pressure coefficients of 1-3.

[0030] In the large-span column-free underground tunnel structure described in Embodiments 1 and 2 of the present invention, the overal...

Embodiment 3

[0031] Embodiment 3: as Figures 1 to 7 As shown, a method for constructing a large-span column-free underground tunnel structure described in Embodiment 1 and Embodiment 2. The present invention takes the six-arch structure of an underground tunnel as an example. The design span of the tunnel is 60m, and there are six tunnel spans, each The span of each cavern is 10m, the maximum design height of the cavern span is 13.5m, the rise-span ratio is 0.23, and the longitudinal length is 105m; the geological conditions are: no confined water, in the IV grade granite formation, the lateral pressure coefficient is 3.0, the scope of the cavern There are 5 penetrating fissures in the interior, which are perpendicular to the axis of the cavern, and the inclination angle of the fissures is 60°-90°, all of which are steep angle fissures;

[0032] The specific construction steps are as follows:

[0033] like figure 1Shown: S1, construction of the first lead tunnel 21; S2, at least 10m be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com