Fabricated gravity finished product support hanger

A hanger and assembly technology, which is applied in the direction of pipe support, rod connection, connecting components, etc., can solve the problems of large environmental pollution, large waste of materials, waste of man-hours, etc., to protect the environment, facilitate later maintenance, and avoid Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

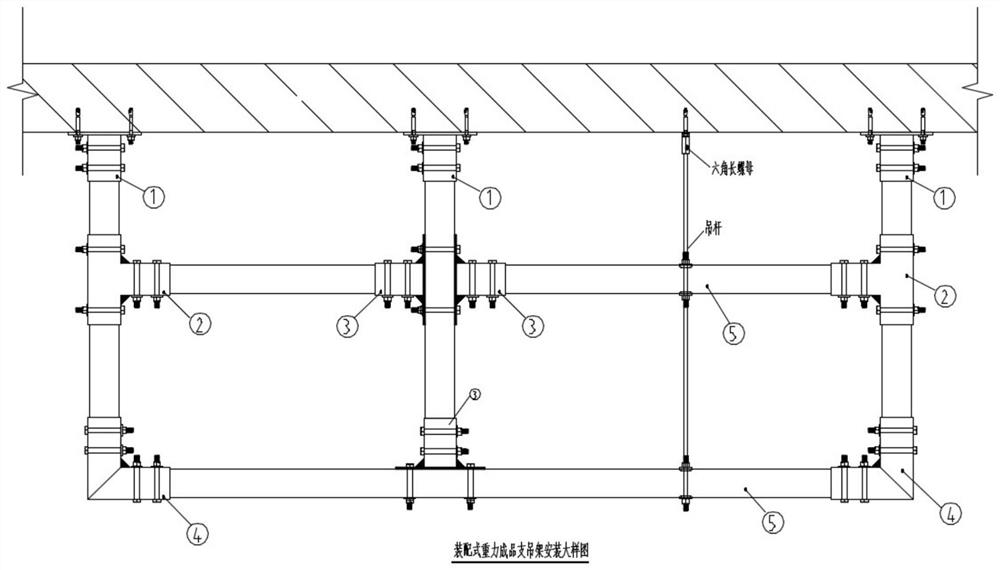

[0027] See figure 1 In the embodiment of the present invention, the assembled gravity bracket is divided into two layers, the first layer of branch hanger vertical, lateral connecting rod (with hole square tube) (5) and (1) (2), (3) Connect, the second layer branch is vertical, lateral connecting rod (with hole square tubes) (5) and (3), (4).

[0028] See image 3 4, 5, in the embodiment of the invention, the assembled gravity finished bracket, the base includes a pad, a square tube.

[0029] Using bolts to secure the pads in the top plate of the body, insert the connecting rod member (with a hole tube) into the intermediate reserved intermediate reserved in the base. Can complete Figure 3 ~ 5 Construction.

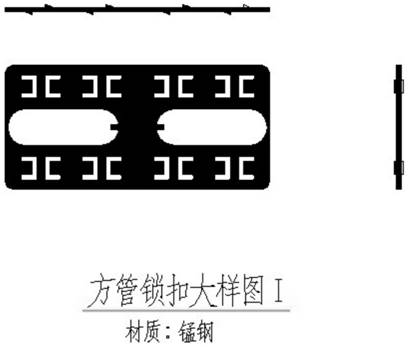

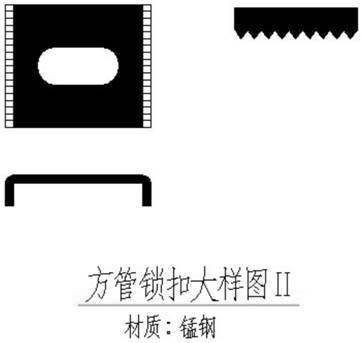

[0030] See Figure 6-14 The T-type connector is connected to the upper base by the connecting rod member (with the hole tube), and the bolt is mounted according to the square tube reserved hole, and the general arrangement is disposed to form a whole.

[0031] See Figure 15-17 ...

Embodiment 2

[0035] See figure 2 In the embodiment of the present invention, the assembled gravity bracket is divided into two layers, the first layer branch is vertical, lateral connecting rod (with hole square tube) (5) and (1) (2), second Layer brackets are vertical, lateral connecting rods (with hole tubes) (5) and (4).

[0036] See image 3 4, 5, in the embodiment of the invention, the assembled gravity finished bracket, the base includes a pad, a square tube.

[0037] Using bolts to secure the pads in the top plate of the body, insert the connecting rod member (with a hole tube) into the intermediate reserved intermediate reserved in the base. Can complete Figure 3 ~ 5 Construction.

[0038] See Figure 6-11 The T-type connector is connected to the upper base by the connecting rod member (with the hole tube), and the bolt is mounted according to the square tube reserved hole, and the general arrangement is disposed to form a whole.

[0039] See Figure 15-17 The L-shaped corner connector is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com