Electric heating device and electric furnace

An electric heating device and heating panel technology, applied in electric heating fuel, ohmic resistance heating parts, lighting and heating equipment, etc., can solve the problems of poor interchangeability, troublesome assembly, different wire lengths, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

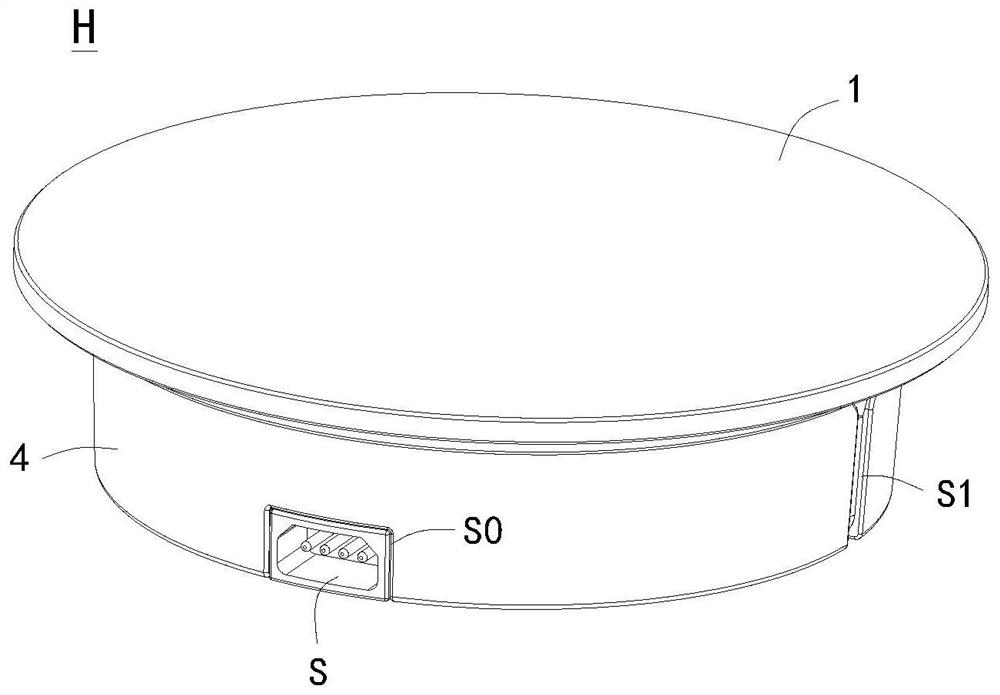

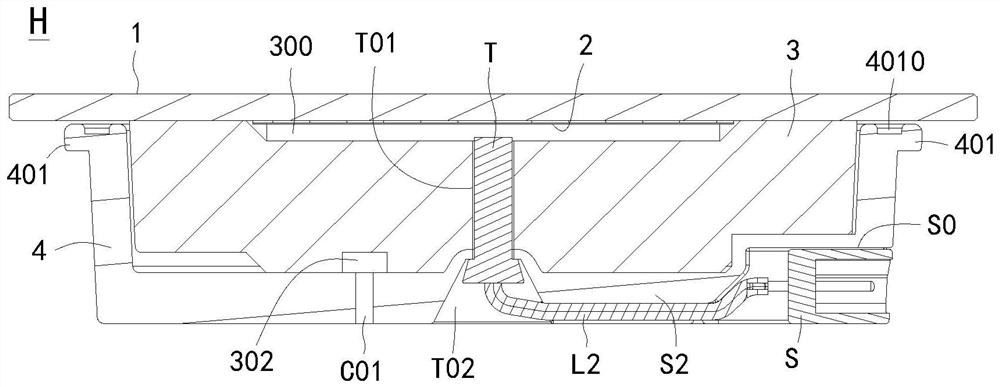

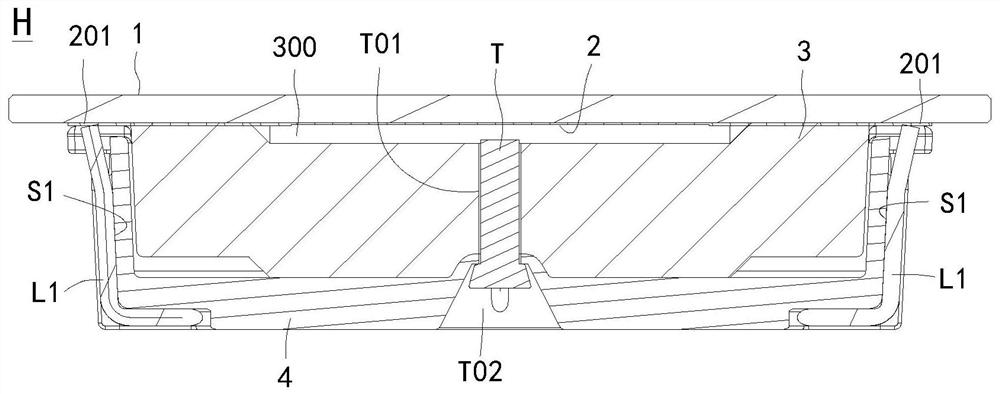

[0050] see Figure 1 to Figure 4 , an electric heating device H, including a heating panel 1, a heating element 2, a heat insulating part 3, a fixed shell 4 and a socket S; The thermal component 3 is provided with a heat insulation cavity 300 with an upper opening for covering the heating element 2, and the fixed shell 4 is provided with a shell cavity 400 with an upper opening for accommodating the heat insulating component 3. The upper end of the fixed shell 4 is glued The bonding material is connected to the heating panel 1, thereby fixing the heat insulating component 3 on the lower side of the heating element 2, and the socket S is electrically connected to the electric connection part 201 through the power supply wire L1. The adhesive material is usually a well-known adhesive material commonly used in electronic components, such as electronic silicone.

[0051] In order to detect the temperature of the heating element 2, a temperature measuring element T is further incl...

Embodiment 2

[0077] see Figure 1 to Figure 14 , Figure 18 , what this embodiment describes is the electric furnace of application embodiment 1 scheme, comprises casing 55, electric heating device H and electric wire assembly (not shown); The opening 501 of the cavity 500 is provided with an assembly step 5011, and the side of the casing 5 is provided with a wire hole 502; the installation and positioning part of the electric heating device H is installed on the upper side of the assembly step 5011; The plug is electrically connected to the socket S through the wire hole 502, and the power line and the detection line are generally packaged in a cable.

[0078] Since the socket S is set on the fixed shell 4 of the electric heating device H, when assembled to the casing 5, the electric wire assembly can be quickly connected to the socket S of the electric heating device H through the plug, and the design space of the external line length is large, and it is interchangeable. Good sex.

[...

Embodiment 3

[0086] see Figure 1 to Figure 14 , Figure 19 , the description of this embodiment is another electric furnace applying the scheme of Embodiment 1, including a casing 5, an electric heating device H, a connecting ring 7 and an electrical lead assembly (not shown); the casing 5 is provided with an upper opening 501 The furnace chamber 500 is provided with an assembly step 5011 around the opening 501 of the furnace chamber 500, and the side of the casing 5 is provided with a wire hole 502; the connecting ring 7 includes a ring wall 701 inserted into the opening 501 of the furnace chamber 500, and the ring is arranged on the The card edge 702 outside the upper end of the ring wall 701, the ring wall 701 connecting the ring 7 is inserted into the opening 501 of the furnace cavity 500, the card edge 702 is fixed on the assembly step 5011, the electric heating device H is assembled in the ring wall 701, and the electric heating The installation and positioning part of the device H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com