Reverse osmosis membrane module pollution in-situ monitoring device and monitoring method

A reverse osmosis membrane module, reverse osmosis membrane technology, applied in the field of reverse osmosis membrane module contamination in-situ monitoring devices, can solve the problems of high additional operating costs, increased pressure drop in the feed channel, high pumping and cleaning costs, etc. The effect of avoiding defects and deficiencies, reducing inspection requirements, and low inspection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

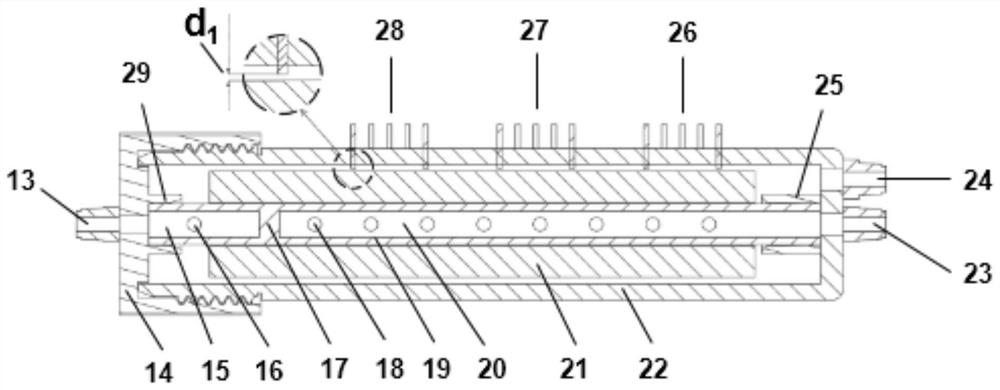

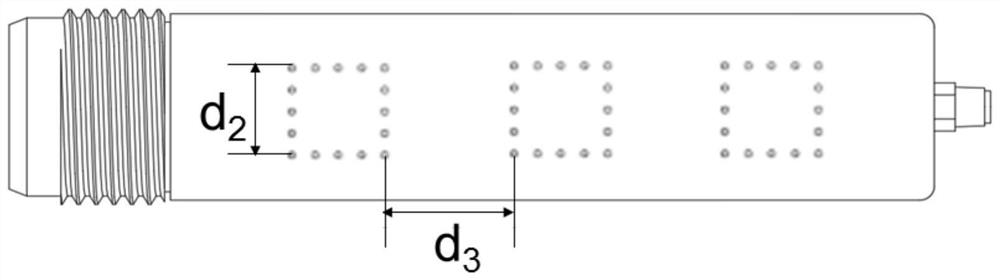

[0030] A reverse osmosis membrane component pollution in-situ monitoring device (see figure 1 and figure 2 ), comprising a reverse osmosis membrane shell 22 and a membrane shell cover 14, the reverse osmosis membrane shell is movably connected with the membrane shell cover; the inner surface of the right side wall of the reverse osmosis membrane shell is provided with a right fixed pipe 25; on the inner surface of the membrane shell cover A left fixed pipe 29 is provided; the two ends of the central pipe 19 are respectively connected with the right fixed pipe and the left fixed pipe; the near left end of the central pipe is provided with a baffle 17, and the baffle 17 divides the central pipe into the water delivery pipe 15 on the left and The water production pipe 20 on the right side, the water inlet pipe 13 runs through the membrane casing cover and connects with the water delivery pipe 15, and the water delivery pipe 15 is provided with a water inlet hole 16; the pure wat...

Embodiment 2

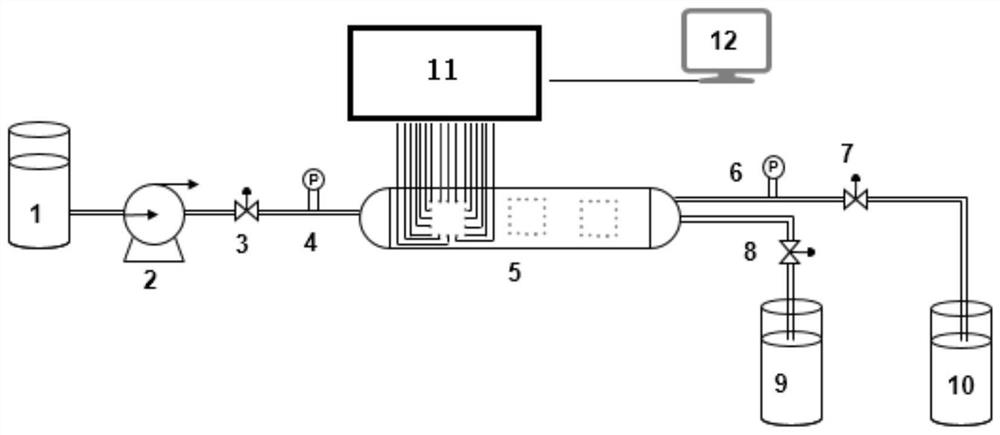

[0038] An in-situ monitoring method for reverse osmosis membrane module contamination, the monitoring system is shown in image 3 , including the following steps:

[0039] 1) The image processing system 12 is connected to the data acquisition and processing unit 11 through wires, the data acquisition and processing unit 11 is provided with 16 wires (also can be 8 or 12), and the 16 wires are connected to the reverse osmosis membrane module pollution source The first electrode array 28 of the position monitoring device (embodiment 1) is connected (also can be connected with the second electrode array 27 or the third electrode array 26);

[0040] 2) Acquisition of empty-field imaging images:

[0041] Through the water supply pump 2, the raw water in the raw water tank 1 (the composition of the raw water in this embodiment is as an example, but not limited to: 0.5g / L yeast, 0.5g / L kaolin, 100mM NaCl and 1mM CaCl 2 , the balance is deionized water) into the water inlet pipe 13 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com