Fuel storage grillwork and assembling method thereof

A technology of fuel storage and grid, which is applied in the direction of reactor fuel elements, reduction of greenhouse gases, reactors, etc., can solve the problems of uncontrollable welding deformation of coamings and columns, unpolishing of coamings, and oxidation of cladding plates, etc., so as to save The effect of time loss, avoiding direct contact with the ground, and reducing installation inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

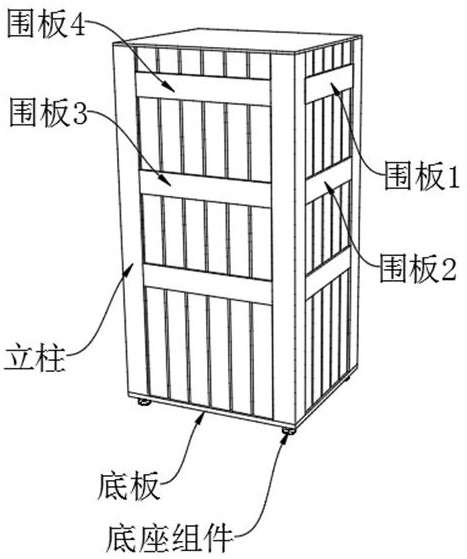

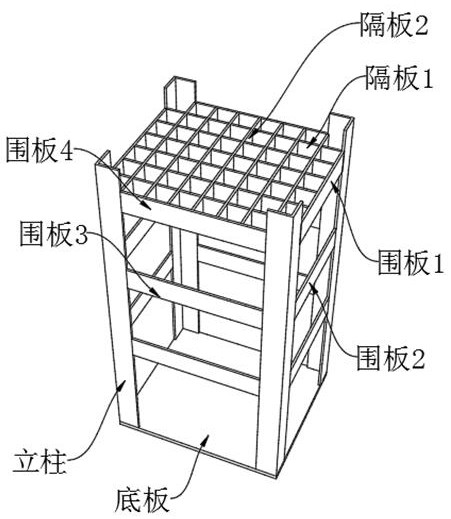

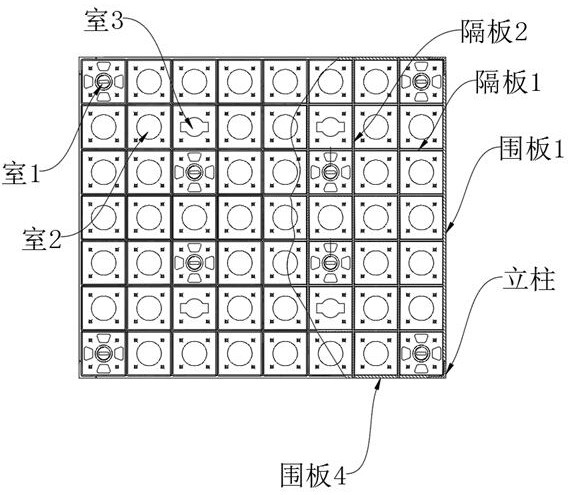

[0031] refer to Figure 1-Figure 4 , a fuel storage grid, comprising: a column, a bottom plate, a coaming assembly and a partition assembly, the four end corners of the upper end of the bottom plate are fixed with columns, the coaming assembly is arranged on the column, the column, the bottom plate, the coaming The components form the main body of the frame, and the partition assembly is arranged inside the frame main body, and is connected to the column through the panel assembly; the vertical assembly method is adopted, and the panel and the column are all welded together first, so that the overall grid size can be controlled, and The back of the weld can be cleaned; and the overall pickling and passivation can be performed.

[0032] Specifically, the panel assembly includes panel 1, panel 2, panel 3, panel 4, both sides of the frame main body are provided with panel 1 and panel 2, both ends of panel 1 and panel 2 are Fixed with the column, the hoarding 1 is located at the ...

Embodiment 2

[0054] On the basis of above-mentioned embodiment 1, disclose its assembly method:

[0055] The first step: according to the size requirements of the grid, weld the coaming and the column, clean the weld, and passivate the whole;

[0056] Step 2: Weld and fix the bottom plate to the bottom of the column, so that the coaming, column and bottom plate form the main body of the frame;

[0057] Step 3: Finally, install partition 1 and partition 2, insert partition 1 into enclosure 1; insert partition 2 into enclosure 4, and buckle together with partition 1 to divide the interior of the frame body into multiple Storage chamber; wherein, the partition 2 can be inserted from the upper end of the enclosure 4;

[0058] Step 4: Install the storage sleeve inside the storage chamber to complete the grid assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com