T-type cable terminal test connector

A technology of cable terminals and connectors, which is applied in the direction of connection, parts of connection devices, devices for joining/disconnecting parts, etc. It can solve the problems of small contact area, weak fixation, poor contact, etc., and achieve safe and reliable connection , Quick disassembly, avoid falling off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

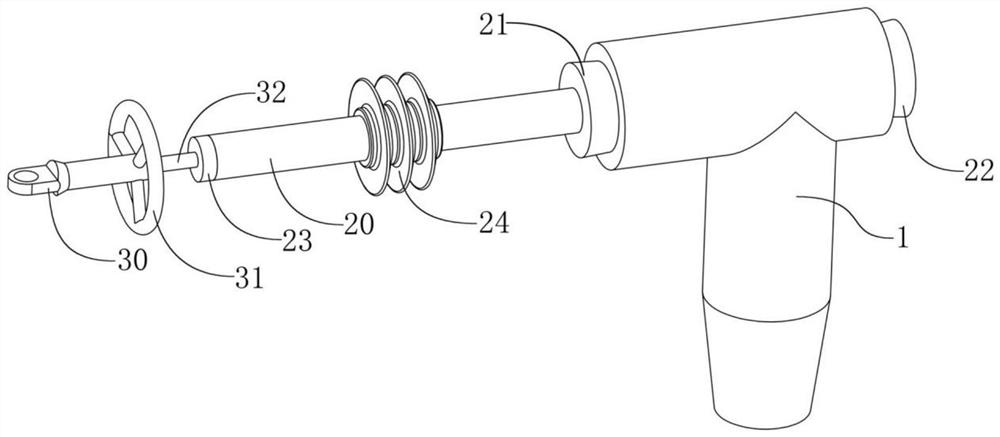

[0052] refer to Figure 1-Figure 2 , the T-shaped cable terminal test connector provided in this embodiment includes a conductive rod 32, and the conductive rod 32 connects from the front port of the cable terminal 1 ( figure 2 The left side in the middle) extends into the connection terminal 11 and is used to lead the cable to the outside of the cable terminal 1, which is convenient for testing the cable.

[0053] The conductive rod 32 is a cylindrical rod, and one end near the connecting terminal 11 is fixedly provided with a conductive sheet 33, the conductive sheet 33 is perpendicular to the conductive rod 32, and is used to fit on the connecting terminal 11, so that the contact between the conductive rod 32 and the connecting terminal 11 The conductive connection is more reliable; one end of the conductive rod 32 away from the terminal 11 is fixedly provided with a test terminal 30 for convenient test connection, and the conductive rod 32 is provided with a voltage equal...

Embodiment 2

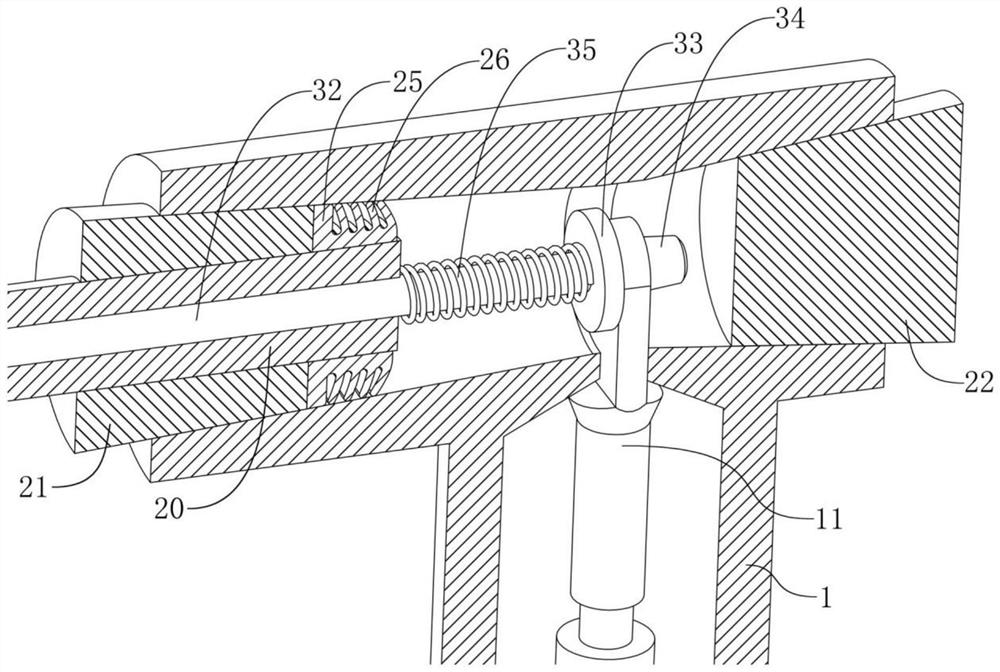

[0068] refer to image 3 Compared with Embodiment 1, the T-shaped cable terminal test connector provided in this embodiment mainly has the following improvements: the conductive rod 32 is threadedly connected with the rear insulating plug 22 .

[0069] Although the conductive rod 32 of Embodiment 1 can be fixed in the cable terminal 1 by the front insulating plug 21, there is still a risk of falling off during the test, so in this embodiment, the conductive rod 32 is screwed to the rear insulating plug 22 , can completely prevent the conductive rod 32 from falling off.

[0070] The positioning seat 34 in this embodiment is a screw structure and is provided with external threads. Correspondingly, a connection seat 36 is fixed vertically at the central position of the side of the rear insulating plug 22 close to the connection terminal 11 , and the connection seat 36 is provided with an internal thread matching the positioning seat 34 . In order to reduce the partial discharge...

Embodiment 3

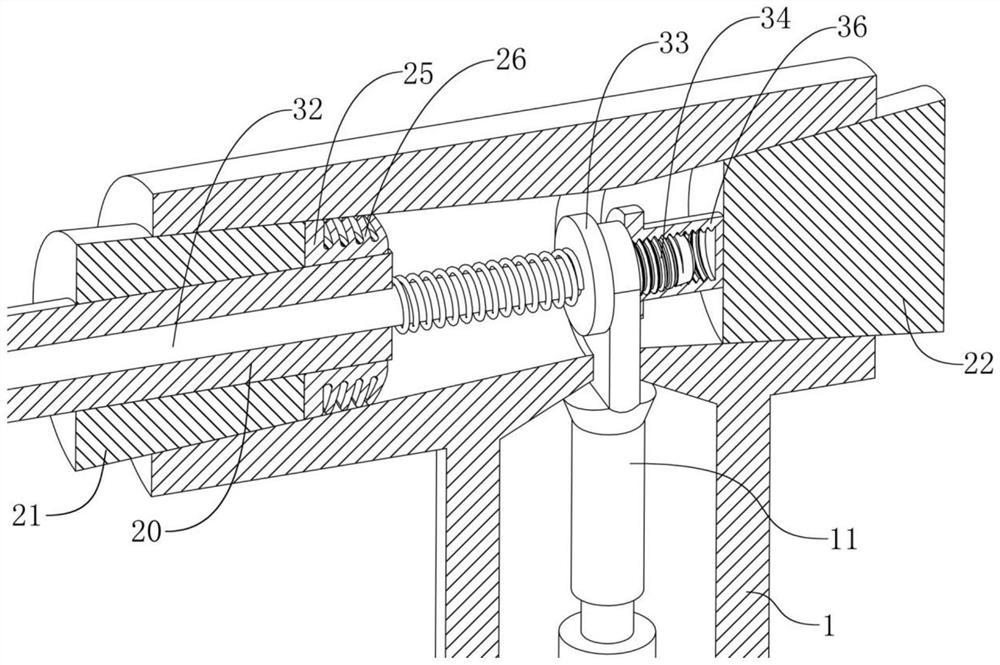

[0080] refer to Figure 4-6 Compared with Embodiment 2, the T-type cable terminal test connector provided in this embodiment mainly has the following improvements: the conductive rod 32 and the rear insulating plug 22 are quickly connected by pressing and clamping structure.

[0081] Although Embodiment 2 can realize the threaded connection between the conductive rod 32 and the rear insulating plug 22, it needs to be rotated and tightened during the connection, and the operation is cumbersome.

[0082]In this embodiment, the positioning seat 34 is a hollow cylindrical structure, and the connecting seat 36 is also a hollow cylindrical structure. The outer diameter of the positioning seat 34 is slightly smaller than the inner diameter of the connecting seat 36. Meanwhile, the connecting seat 36 is also provided with a positioning rod 37 along the central axis, the outer diameter of the positioning rod 37 is slightly smaller than the inner diameter of the positioning seat 34, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com