A common mode peak suppression method for robot servo driver imc

A servo driver, robot technology, applied in the direction of AC motor control, control system, output power conversion device, etc.

Active Publication Date: 2022-06-03

HEBEI UNIV OF TECH

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing suppression of the common-mode voltage of the indirect matrix converter is mainly achieved by avoiding the use of zero vectors or by reasonably placing the position of the zero vectors to suppress the common-mode voltage at the time of the zero-vector, which can only suppress 42% of the peak value of the common-mode voltage %

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0163]

[0169] To sum up, in the case of the voltage transfer ratio of m=0.2 and m=0.4, the machine of the present invention was tested experimentally.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

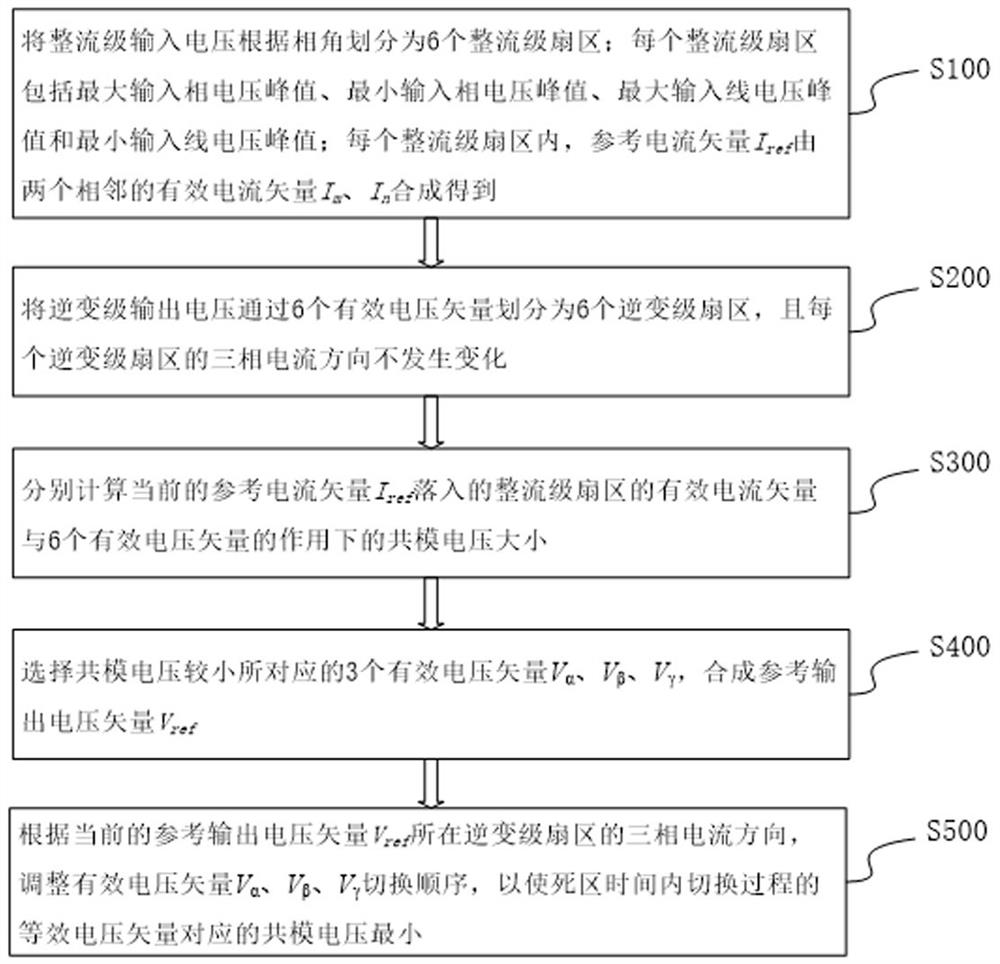

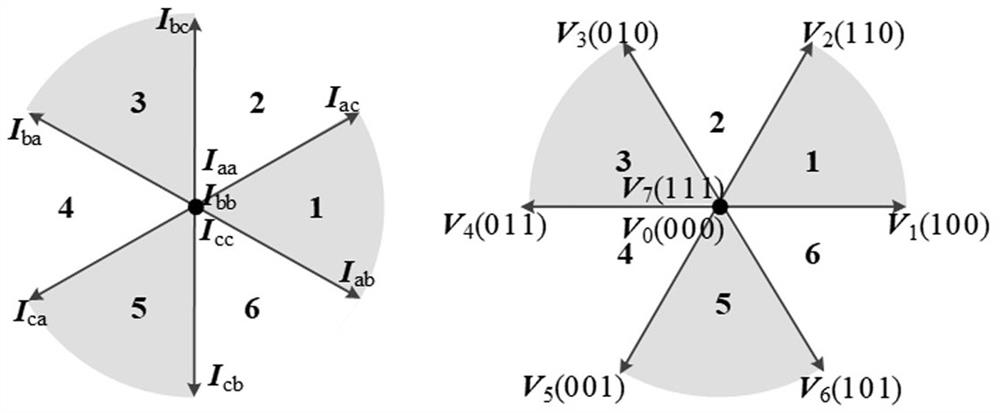

The application provides a common mode peak suppression method for a robot servo driver IMC, comprising the following steps: dividing the input voltage of the rectification stage into 6 rectification stage sectors according to the phase angle; in each rectification stage sector, the reference current vector is composed of two Two adjacent effective current vectors are synthesized; the output voltage of the inverter stage is divided into six inverter stage sectors by six effective voltage vectors; the effective current vector of the rectification stage sector where the current reference current vector falls into is calculated respectively The magnitude of the common-mode voltage under the action of 6 effective voltage vectors; select the 3 effective voltage vectors corresponding to the smaller common-mode voltage V α , V β , V γ , synthesize the reference output voltage vector; adjust the effective voltage vector according to the three-phase current direction of the inverter stage sector where the current reference output voltage vector is located V α , V β , V γ Switch order. The method provided in the present application can suppress the common-mode voltage to 29%, and eliminate the common-mode voltage spike generated by the dead zone effect.

Description

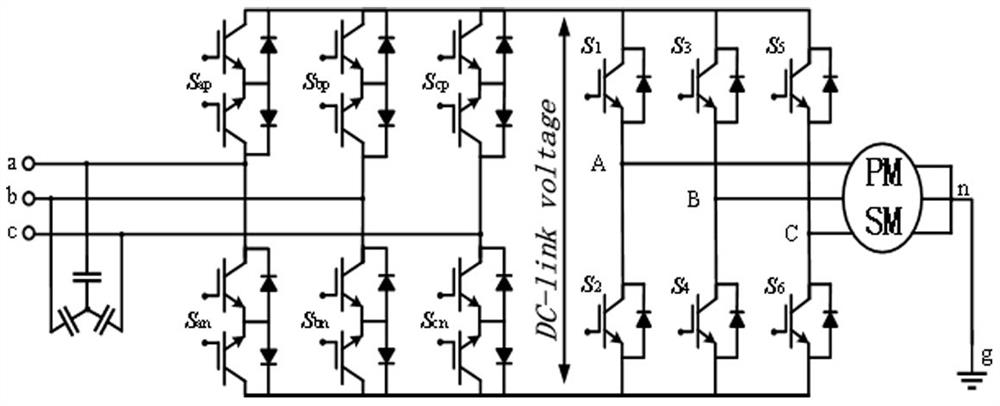

A common mode peak suppression method for robot servo driver IMC technical field The present disclosure generally relates to the technical field of indirect matrix converters, in particular to a robot servo driver IMC common-mode peak suppression method. Background technique Servo drive system is one of the key parts of the robot, and its reliability directly affects whether the robot can be normal or not. Complete work tasks. Indirect matrix converter (IMC) is a new type of AC- AC converter, with sinusoidal input and output current, controllable power factor, no intermediate energy storage link, energy can flow in both directions, etc. With many advantages, it has become a new generation of robot servo drives with great application prospects. [0003] The indirect matrix converter will produce high frequency and high amplitude changes at the neutral point of the output load during operation. The common-mode voltage (CMV) of a high-frequency and high-amplitude com...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02M1/12H02M5/458H02M7/219H02M7/5387H02P27/06

CPCY02B70/10

Inventor 韩旭李珊瑚鲁紫荆陶友瑞操孙鹏段书用

Owner HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com