Film heater

A thin-film heater and heating chamber technology, applied in ohmic resistance heating, electric heating devices, tobacco, etc., can solve the problems of increased manufacturing cost, increased thermal mass, and expensive polyimide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

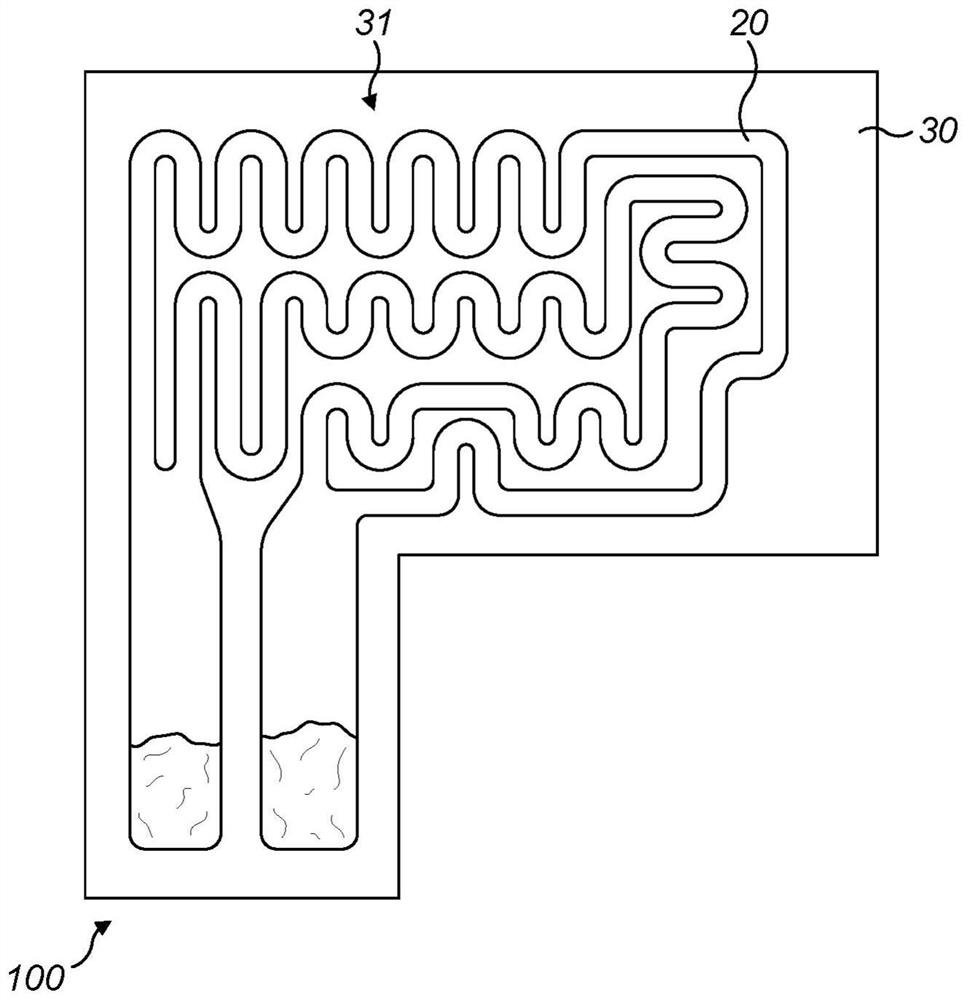

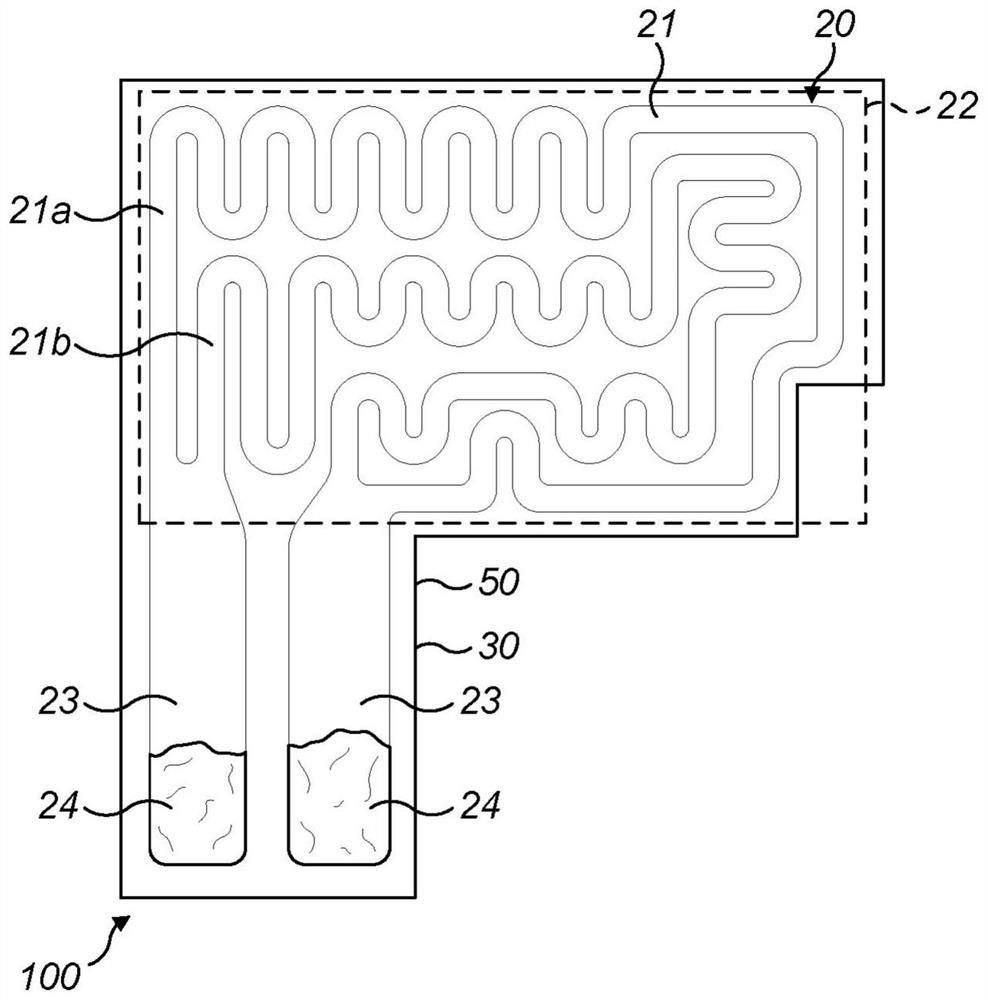

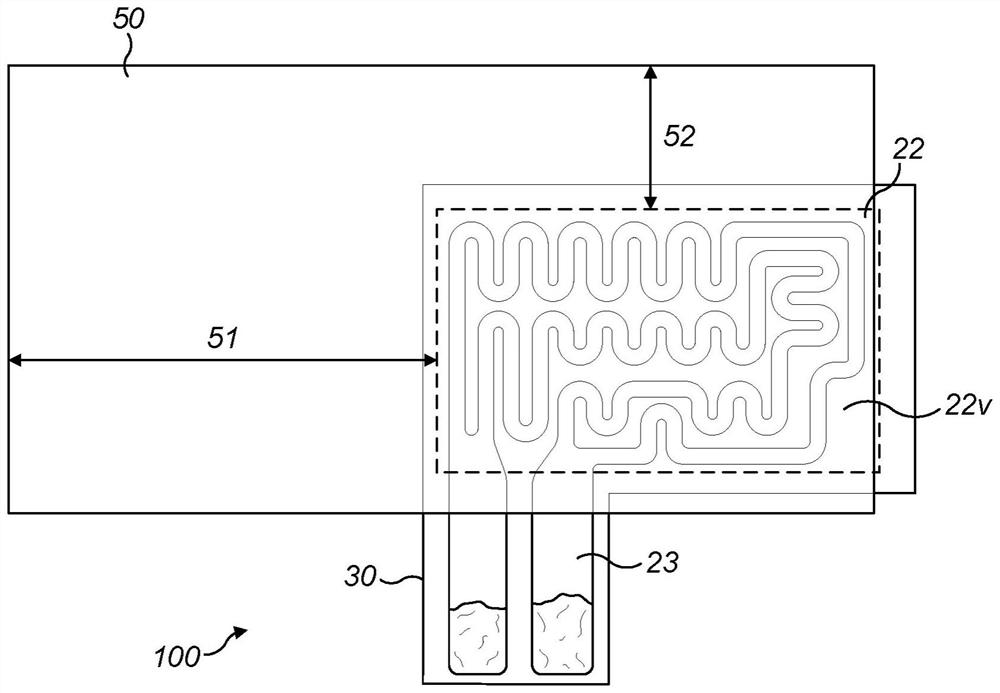

[0055] figure 1 A membrane 100 is schematically shown comprising a flexible heating element 20 and a flexible electrically insulating backing film 30 supporting the heating element 20, wherein the backing film 30 comprises a fluoropolymer or PEEK. Fluoropolymers and PEEK have a number of favorable properties that are maintained over a wide range of operating temperatures, and thus can be used as the dielectric layer in thin film heater 100 . In particular, these materials have improved electrical insulation properties over conventional materials, which means that the thickness of the film can be reduced to reduce thermal mass and enhance heat transfer from the heating element to the structure to be heated, such as the heating chamber of an aerosol generating device. ) transmission.

[0056] Fluoropolymers and PEEK are materials characterized as being highly resistant to solvents, acids and bases, and having good dielectric properties and maintaining their mechanical propertie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com