Lifting type material transfer sealing automatic butt joint mechanism

A technology of automatic docking and docking mechanism, which is applied in mixers, transportation and packaging, mixer accessories, etc. It can solve the problems of docking mechanism defects, dust raising, and it is difficult to meet the dust cleaning requirements, and achieve simple structure , convenient processing and production, and the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

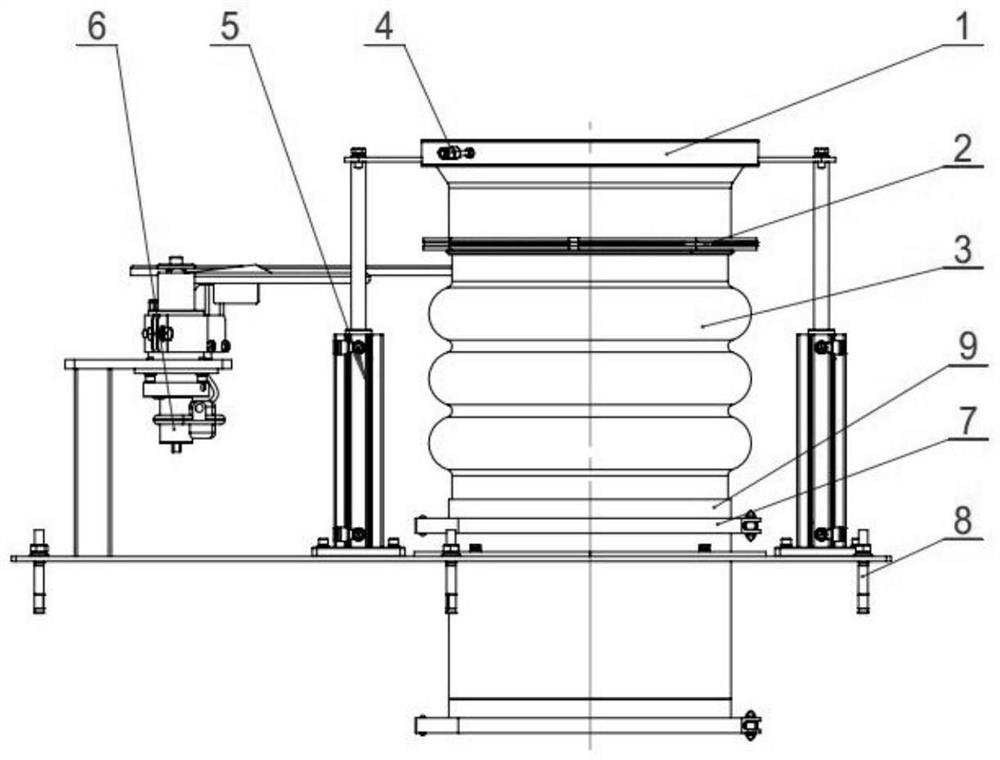

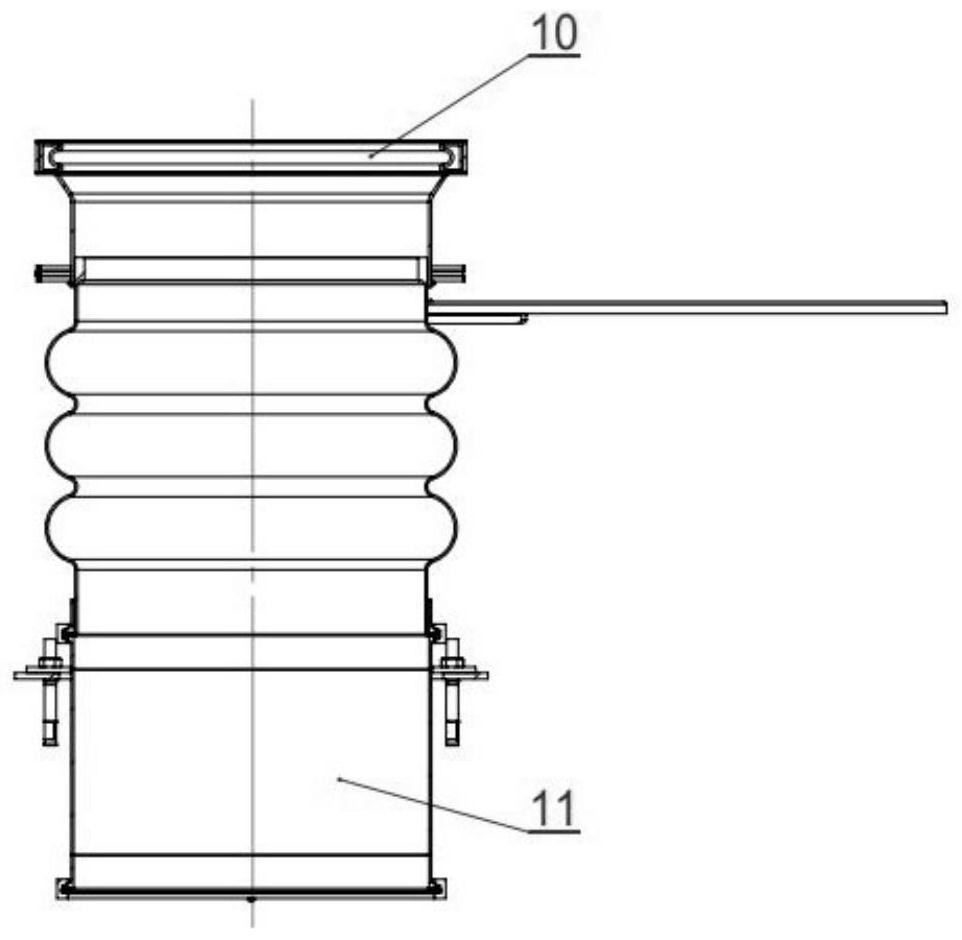

[0043] Such as Figure 1-Figure 5 As shown, a lift-type material transfer sealing automatic docking mechanism, the fixed bottom plate 13 is fixed on the ground through the expansion bolt 8, and the discharge is realized through the docking of the airbag mounting seat 1 and the discharge port.

[0044] When unloading is required, after the docked discharge port is moved or rotated to a designated position, the system controls the solenoid valve to control the rotation of the swing cylinder 6, and then realizes that the isolation material tray 12 is opened to a limited angle, and the lifting cylinder 5 starts to lift, and the sensor After the induction is in place, the airbag 10 starts to inflate through the inflation and deflation nozzle 4, and the airbag 10 expands and seals with the tube wall of the discharge port. After feeding back to the system, the discharge starts. After the unloading is completed, by controlling the deflation of the air bag 10, the air bag 10 shrinks an...

Embodiment 2

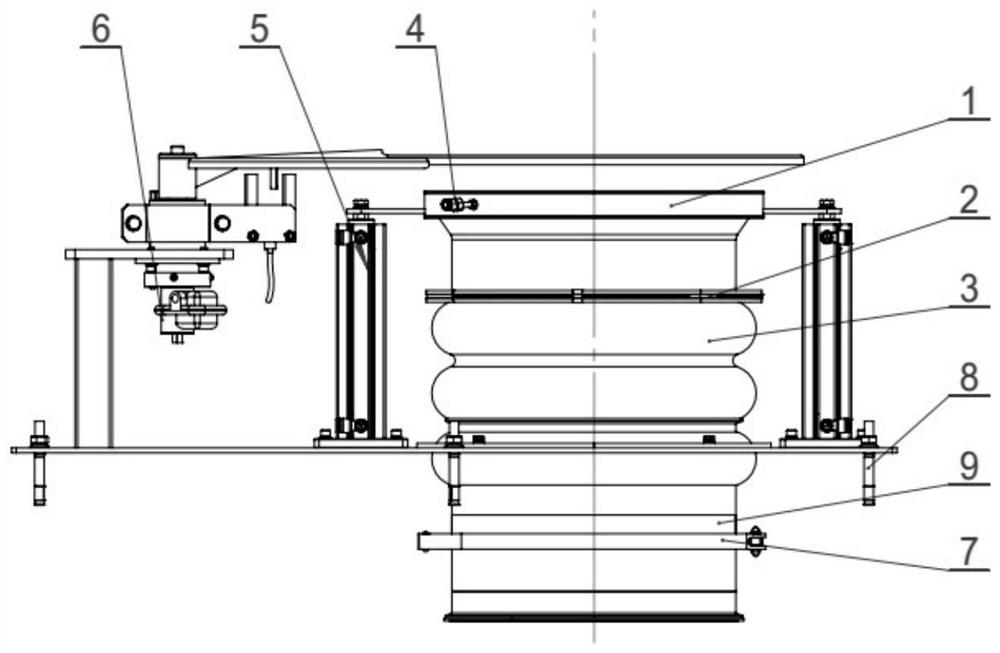

[0046] Such as Figure 6-Figure 10 As shown, a lifting type material transfer sealing automatic docking mechanism, the fixed bottom plate 13 is fixed on the top surface by the expansion bolt 8 and the docking mechanism is turned over, and the material is connected by docking the airbag mounting seat 1 with the material connection port.

[0047] When material needs to be received, after the material receiving port that needs to be docked moves or rotates to the designated position, the system controls the solenoid valve to control the rotation of the swing cylinder 6, and then the isolation material tray 12 is opened to a limited angle, and the lifting cylinder 5 begins to descend, and the sensor After sensing in place, the airbag 10 starts to inflate through the inflation and deflation nozzle 4, and the airbag 10 expands inwardly and seals with the outer wall of the material receiving port tube. After feeding back to the system, the material receiving starts. After receiving t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com