Modular ozone generator with contact cooling

An ozone generator and contact cooling technology, which is applied in the direction of ozone preparation, ozone preparation by discharge method, oxygen/ozone/oxide/hydroxide, etc., can solve the problems of low discharge efficiency, increase the amount of ozone, easy to observe and Monitor and accurately produce the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described below with reference to the drawings.

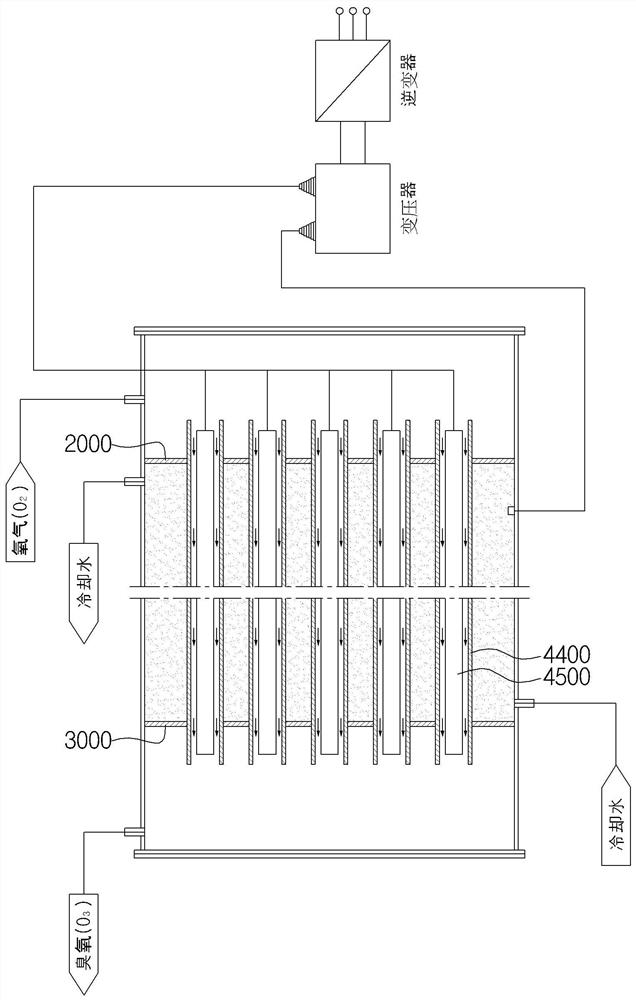

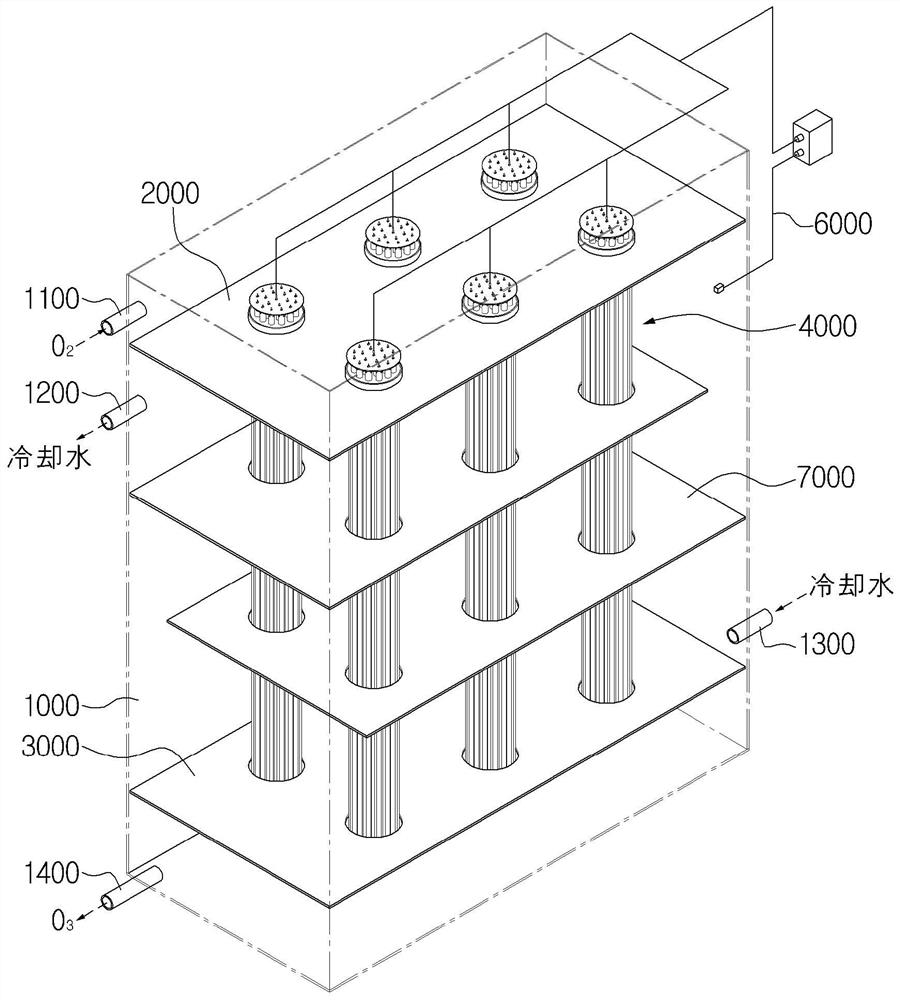

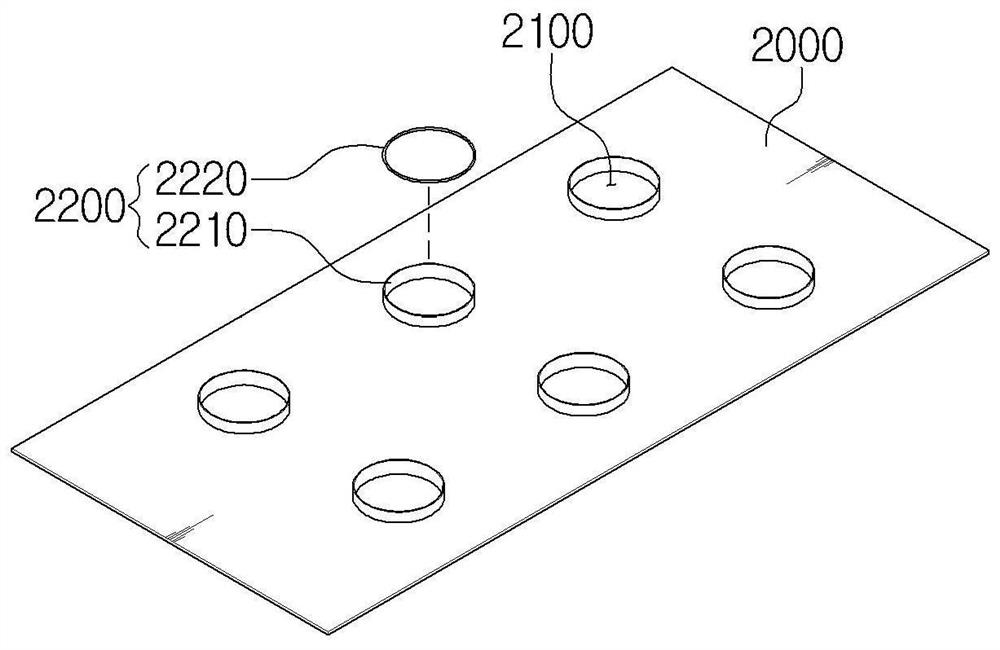

[0030] The modular ozone generator adopting contact cooling of the present invention includes: a main body 1000 of a predetermined shape, formed by a non-conductive material that does not flow current; an upper separation part 2000, which divides the interior of the main body 1000 into an upper region where oxygen flows; the lower part is separated The part 3000 divides the inside of the main body 1000 into the lower area for discharging ozone; the ozone generator 4000 penetrates the upper separation part 2000 and the lower separation part 3000 and is detachably fastened, and has a plurality of discharge electrodes 4500 installed inside. The thin tube 4400 receives oxygen from the upper end and discharges the generated ozone to the lower end; the cooling water 5000 is supplied between the upper separation part 2000 and the lower separation part 3000; Also, a cooling water baffle 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com