Method for determining water inlet speed of cooling water through convective heat transfer

A technology of water inlet speed and convective heat transfer, applied in glass forming, glass rolling, glass manufacturing equipment, etc., can solve the problems of slow water inlet speed, glass cracks, glass sticking rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention can be further clearly understood through the examples given below, but they are not limitations of the present invention.

[0014] A method for determining the cooling water inlet velocity through convective heat exchange, comprising the following steps:

[0015] (1) Before starting the machine, use a vernier caliper to accurately measure the inner diameter r of the calender roll 0 180mm and calender roll length l 0 3250mm;

[0016] (2) Measure the inner diameter of the water inlet pipe, and calculate the cross-sectional area S of the water inlet according to the area formula to be 6000mm 2 ;

[0017] (3) After the start-up and preheating are stable, use a thermometer to measure the inlet temperature T of the cooling water 3 20°C, outlet water temperature T 4 60°C; use a thermocouple to measure the temperature T of the inner surface of the calender roll 2 80°C;

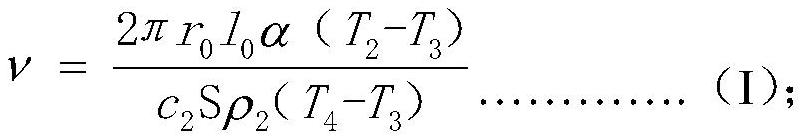

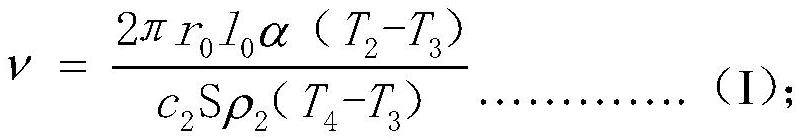

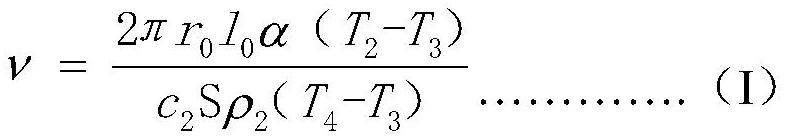

[0018] (4) Substituting the above-mentioned measured parameters into formula (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com