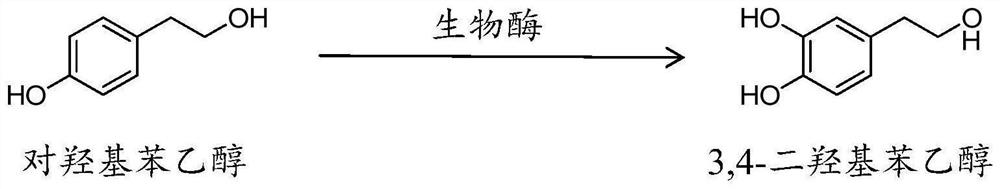

Method for preparing 3, 4-dihydroxyphenethyl alcohol through biological enzyme catalysis

A technology of dihydroxyphenylethanol and p-hydroxyphenylethanol, which is applied in the field of biological enzyme catalysis to prepare 3,4-dihydroxyphenylethanol, can solve the problems of low purity, low yield, and low output of hydroxyphenylethanol, and meet the needs of the market required, high catalytic efficiency, and low substrate residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Place the Escherichia coli MG1655 fermentation broth induced to produce enzymes in a centrifuge tube, centrifuge for 3 minutes in a centrifuge with a rotating speed of 2000rpm / min, remove the centrifuge supernatant, and collect the bacteria;

[0032] (2) Add 90ml PB buffer solution to the thalline to suspend the thalline, and the biomass of the thalline is 15g / m 3 , and then pour it into a four-necked flask, then put the four-necked flask into a magnetic stirring water bath with a rotating speed of 200rpm / min and a temperature of 25°C, and then feed oxygen into the bacterial suspension at an oxygen flow rate of 0.5L / min. And use ammonia water to adjust the pH value to 5.5 in real time;

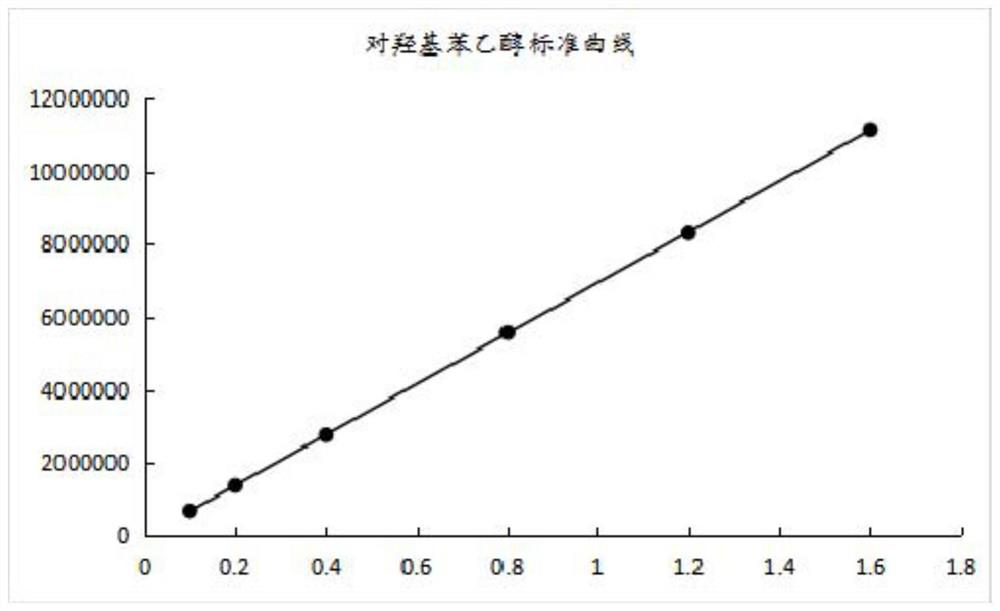

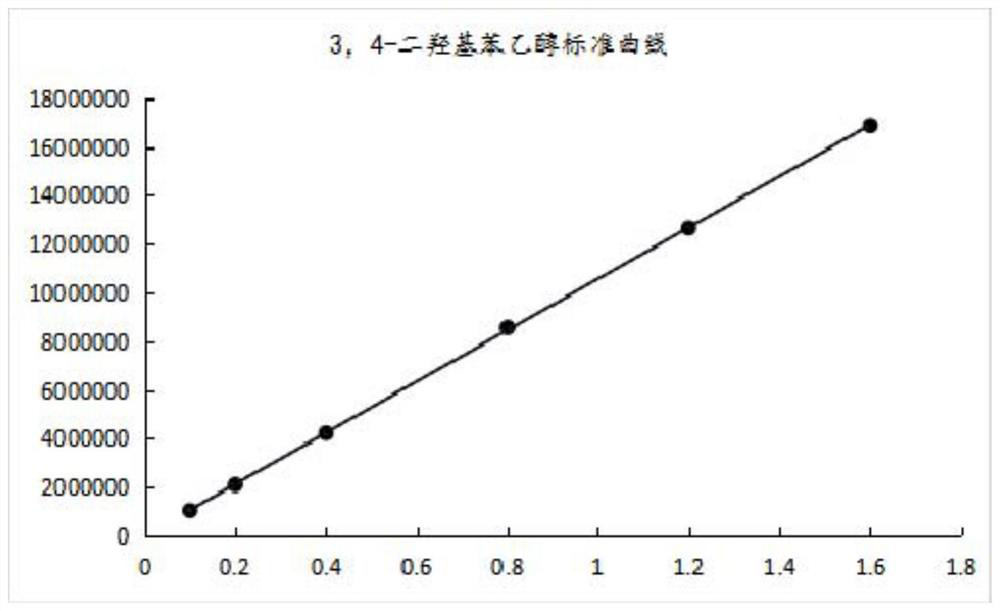

[0033] (3) Weigh 0.5g of p-hydroxyphenylethanol substrate, dissolve it in 10ml of PB buffer, after it is completely dissolved, add 0.5g / 30min dropwise into the four-neck flask once, and keep stirring for reaction, and then pass the liquid phase detection The p-hydroxyphenylethanol ...

Embodiment 2

[0035] (1) Place the Escherichia coli MG1655 fermentation broth induced to produce enzymes in a centrifuge tube, centrifuge for 3 minutes in a centrifuge with a rotating speed of 2000rpm / min, remove the centrifuge supernatant, and collect the bacteria;

[0036] (2) Add 40ml PB buffer solution to the thalline to suspend the thalline, and the biomass of the thalline is 42g / m 3 , and then pour it into a four-necked flask, then put the four-necked flask into a magnetic stirring water bath with a rotating speed of 200rpm / min and a temperature of 25°C, and then feed oxygen into the bacterial suspension at an oxygen flow rate of 0.5L / min. And use ammonia water to adjust the pH value to 5.5 in real time;

[0037](3) Weigh 0.5g of p-hydroxyphenylethanol substrate, dissolve it in 1.5ml PB buffer solution, completely dissolve and mix well, then add dropwise at 0.5g / 30min in a four-neck flask, and keep stirring for reaction, then Detect the p-hydroxyphenylethanol substrate in the reactio...

Embodiment 3

[0039] (1) Place the Escherichia coli MG1655 fermentation broth induced to produce enzymes in a centrifuge tube, centrifuge for 3 minutes in a centrifuge with a rotating speed of 2000rpm / min, remove the centrifuge supernatant, and collect the bacteria;

[0040] (2) Add 250ml PB buffer solution to the thalline to suspend the thalline, and the biomass of the thalline is 15g / m 3 , and then pour it into a four-necked flask, then put the four-necked flask into a magnetic stirring water bath with a rotating speed of 200rpm / min and a temperature of 25°C, and then feed oxygen into the bacterial suspension at an oxygen flow rate of 0.5L / min. And use ammonia water to adjust the pH value to 5.5 in real time;

[0041] (3) Weigh 3.25g of p-hydroxyphenylethanol substrate, dissolve in 20ml of PB buffer, completely dissolve and mix well, then add dropwise to the four-necked flask five times at 0.65g / 30min, and keep stirring for reaction, then Detect the p-hydroxyphenylethanol substrate in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com