Accident-resistant forged steel supporting roll

A back-up roll and forged steel technology, which is applied in the field of accident-resistant forged steel back-up rolls, can solve the problems of reducing the roll’s anti-accident ability, uneven wear of the roll surface, and abnormal hardness of the subsurface, so as to improve the solidification quality and reduce component segregation , reduce the effect of hardness drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention is described in further detail:

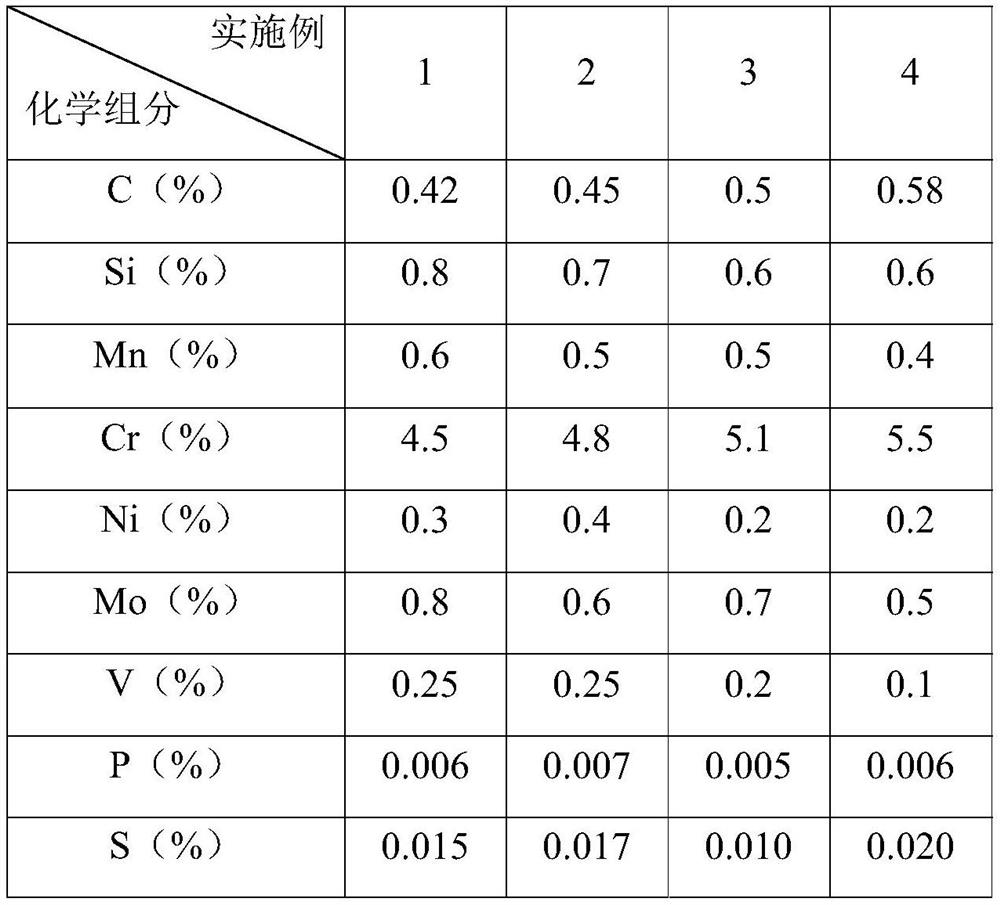

[0028] An anti-accident type forged steel support roll, the chemical composition and weight percentage of the material of the support roll are:

[0029] C: 0.40% to 0.60%, Si: 0.60% to 1.00%, Mn: 0.30% to 0.80%, Cr: 4.00% to 6.00%, Ni: 0.10% to 0.40%, Mo: 0.50% to 0.90%, V: 0.10~0.30%, P≤0.010%; S≤0.020%; the rest is Fe and impurities;

[0030] The working layer of the back-up roll is a tempered troostite structure with a surface hardness ≥ 60HSD.

[0031] The following process steps are used:

[0032] 1) Prepare steel raw materials according to the chemical composition and weight percentage in the newly designed material, and make steel ingots according to the production process of the smelting process;

[0033] 2) The steel ingot is made into a roll blank according to the production process of the forging process;

[0034] 3) Quenching and tempering the roll blank: the rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com