Outer sealing structure of hydraulic oil cylinder

A hydraulic oil cylinder and external sealing technology, applied in the field of oil cylinder sealing, can solve problems such as the influence of oil cylinder accuracy and quality, the aging of the sealing ring, and the weakening of the sealing performance, so as to improve the sealing effect, make up for the deterioration of the sealing, and reduce the effect of the influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

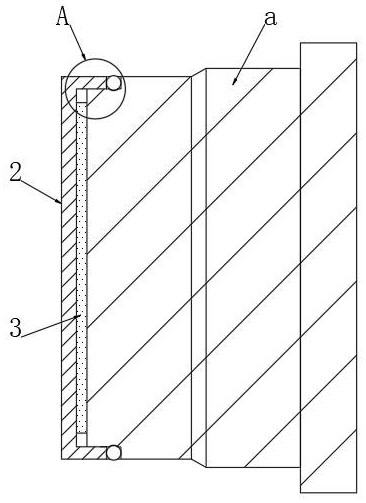

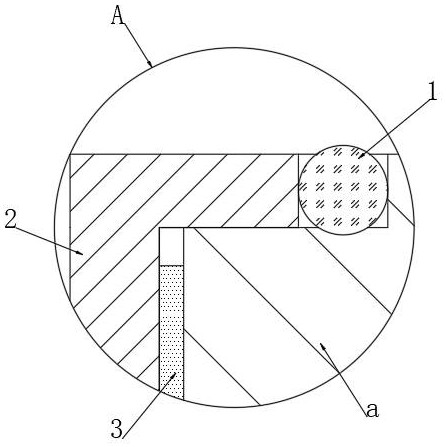

[0036] see Figure 1-Figure 2 , a in the figure represents the end cover, an external sealing structure of a hydraulic cylinder, including a ring body 1 sleeved on the end cover of the oil cylinder near the inner and outer ends of the oil cylinder and an auxiliary sealing cover 2 that cooperates with the end cover near the inner end of the oil cylinder. The cover 2 and the ring body 1 are in contact with each other, and a self-resetting connecting layer 3 is fixedly connected between the auxiliary sealing cover 2 and the end face of the oil cylinder end cover.

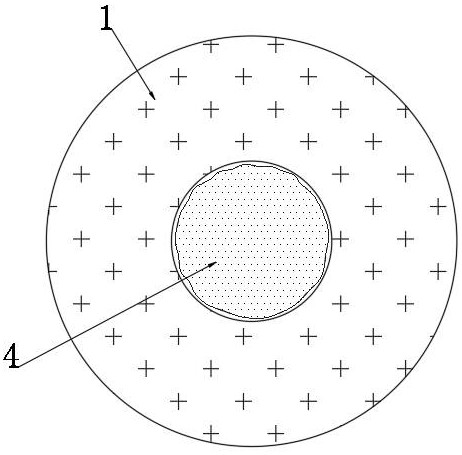

[0037] see Figure 3-Figure 4 , the ring body 1 is a hollow circular structure, and when it is hollow, it deforms faster and easier in the radial direction when it is stressed, so that the sealing performance is better. The inner flexible support ring 4 is placed in the hollow inner cavity of the ring body 1 , the inner flexible support ring 4 plays the role of flexible support for the ring body 1 in the hollow cavity...

Embodiment 2

[0045] Such as Figure 9 As shown: the edge section of the ring body 1 close to the inner wall of the oil cylinder is a double convex structure, and a U shape is formed between the double convex, and a sealing ring 6 is embedded in the U shape, and the outer surface of the sealing ring 6 is lower than the convex surface , and both surfaces are in contact with the inner wall of the oil cylinder. Under the action of the convex structure, the contact force between the sealing ring 6 and the inner wall of the oil cylinder is relatively small, making the aging speed slower than that of the ring body 1, so that the ring body 1 After aging, it can continue to play a sealing role, so as to prolong the service life of the ring body 1 and the sealing effect.

[0046] In this embodiment, due to the setting of the convex structure, the sealing contact between the ring body 1 and the inner wall of the oil cylinder is double-layered to achieve a double-layer sealing effect. The further inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com