Multi-section continuous drum furnace

A drum furnace, multi-stage technology, applied in the field of heating furnace, can solve the problems of easy backlog of materials discharged from the heating furnace, difficult maintenance, etc., and achieve the effects of saving energy, improving service life, and facilitating discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

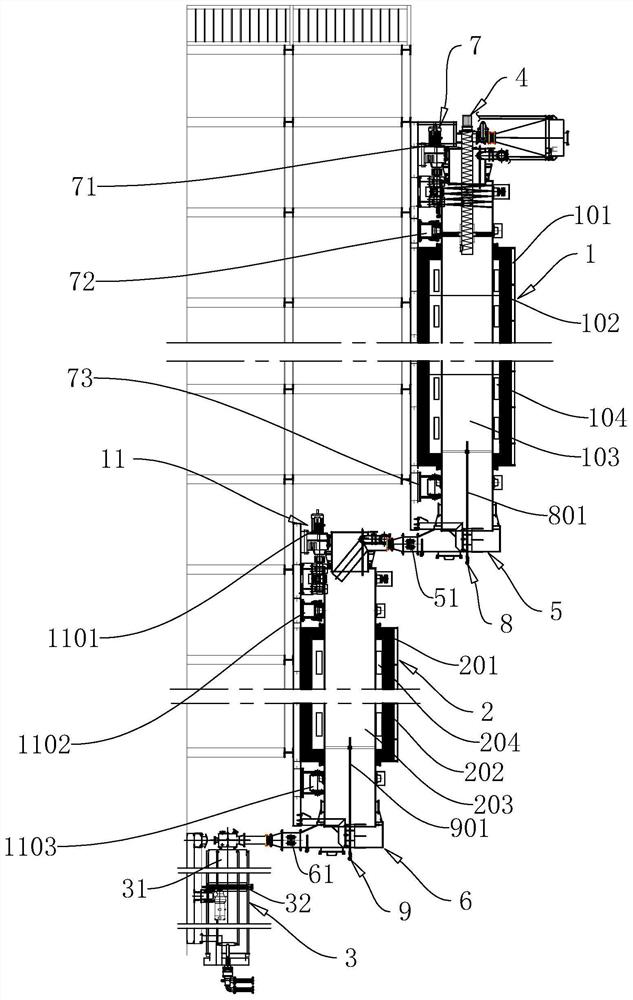

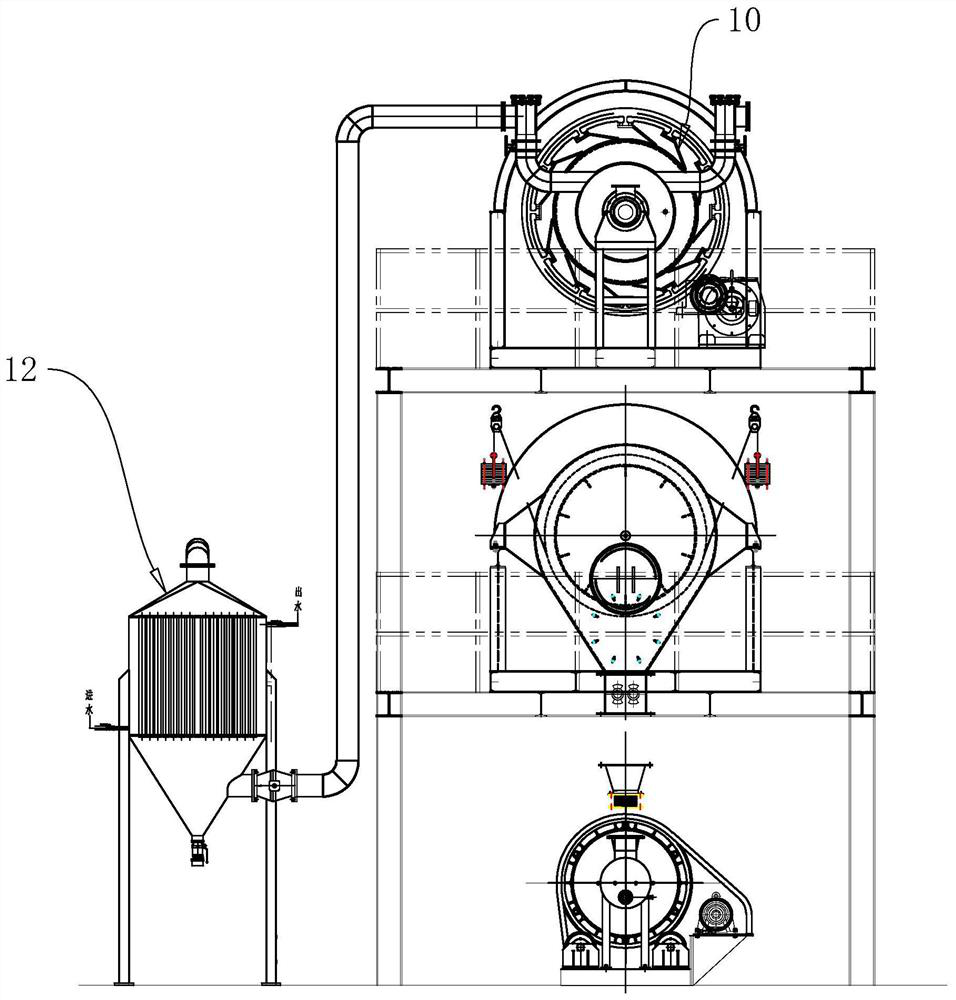

[0042] refer to figure 1 and figure 2 , This embodiment discloses a multi-stage continuous roller furnace. This embodiment adopts a three-stage continuous roller furnace, which includes a low-temperature section furnace body 1 , at least one high-temperature section furnace body 2 and a discharge cooling mechanism 3 . The furnace body 1 in the low-temperature section, the furnace body 2 in the high-temperature section, and the discharge cooling mechanism 3 are arranged in sequence along the length direction. The feed end of the furnace body 1 in the low temperature section is connected with a set of electric screw machine 4, and the electric screw machine 4 is connected with a feed bin for feeding into the furnace body 1 in the low temperature section. The discharge end of the furnace body 1 in the low temperature section is connected to the feed end of the furnace body 2 in the high temperature section through the first collection bin 5, and the discharge end of the furnace...

Embodiment 2

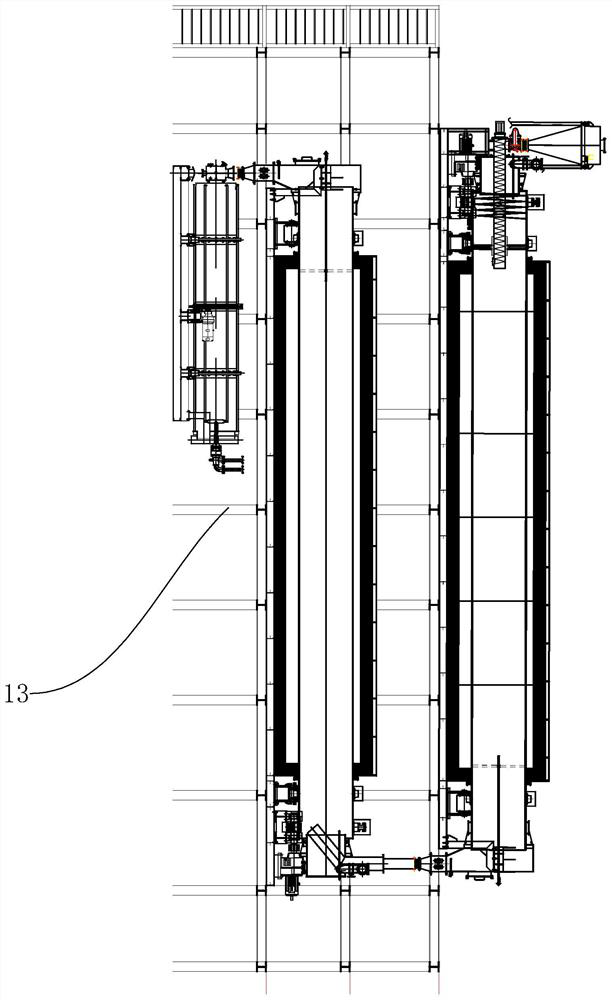

[0061] refer to image 3 , the rest of this embodiment is the same as that of Embodiment 1. The difference is that in order to reduce the requirements for the workshop in production, in this embodiment, a frame 13 is provided, and the frame 13 is a structure of upper and lower layers. In this embodiment, Among them, the furnace body 1 of the low temperature section is installed on the uppermost layer of the frame 13 , the furnace body 2 of the high temperature section is arranged on the middle layer of the frame 13 , and the discharge cooling mechanism 3 is installed on the bottom layer of the frame 13 .

Embodiment 3

[0063] refer to Figure 4 and Figure 5, the rest of this embodiment is the same as Embodiment 1 or Embodiment 2. The difference is that if the low-temperature heating part 104 between the low-temperature furnace shell 101 and the low-temperature drum 103 fails, in order to reduce the time for downtime maintenance, this embodiment Among them, the low temperature heating part 104 is set to the following structure:

[0064] The low-temperature heating part 104 includes a heating seat 1041 and an electric heating wire 1042 arranged on the heating seat 1041. The heating seat 1041 is an annular structure. The inner ring of the heating seat 1041 is also provided with a moving plate 1043, and the moving plate 1043 is coated with a high temperature resistant heat insulating material. Slots 1011 distributed along the axial direction of the low temperature furnace shell 101 are also provided on the low temperature furnace shell 101 ; and guide seats 1012 are provided on the low temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com