High-stability micro-foaming quantum dot diffusion plate and preparation method and application thereof

A quantum dot and micro-foaming technology, which is applied in the field of highly stable micro-foaming quantum dot diffusion plate and its preparation, can solve the problems of brightness attenuation, warpage, low distribution uniformity, etc., and achieves fine foaming pore size, excellent The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~18

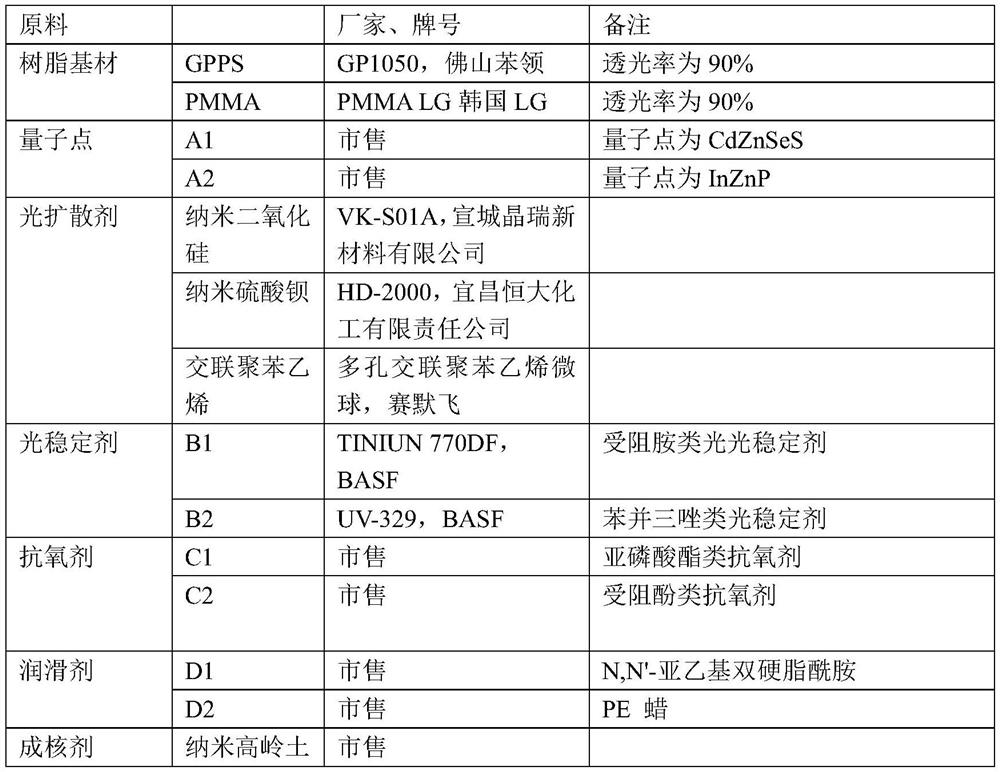

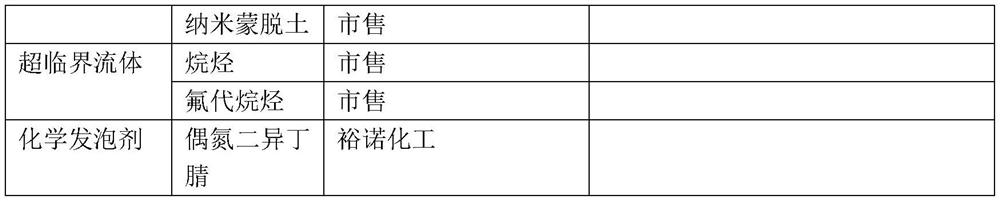

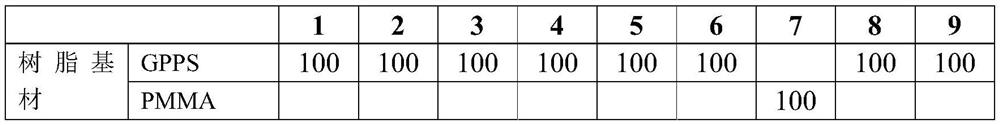

[0050] Embodiments 1 to 18 respectively provide a microfoamed quantum dot diffusion plate, the component contents are shown in Table 1, and the preparation method is as follows:

[0051]S1. Disperse the quantum dots in an organic solvent to obtain a quantum dot solution;

[0052] Wherein the quantum dot of embodiment 1 is CdZnSeS, the organic solvent is toluene, and the quantum dot concentration is 10wt.%; The quantum dot of embodiment 2 is CdZnSeS, and the organic solvent is toluene, and the quantum dot concentration is 30wt.%. The point is CdZnSeS, the organic solvent is toluene, and the quantum dot concentration is 5wt.%; the quantum dot of embodiment 4 is CdZnSeS, the organic solvent is toluene, and the quantum dot concentration is 40wt.%; the quantum dot of embodiment 5 is InZnP, and the organic solvent It is n-hexane, and the quantum dot concentration is 10wt.%. The quantum dot of embodiment 6 is CdZnSe, and the organic solvent is styrene, and the quantum dot concentrati...

Embodiment 1

[0059] Embodiments 19 to 22 respectively provide a microfoamed quantum dot diffusion plate, the component content is the same as that of Example 1, and the difference between the preparation method and Example 1 is that in step S3:

Embodiment 19

[0060] The pressure of the supercritical fluid of embodiment 19 is 20MPa, and feed rate is 30mL / min;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com