Protection circuit for preventing atomization sheet and coupler from electrolyzing

A technology for protecting circuits and coupling circuits, applied to instruments, electrical components, and adjusting electrical variables, etc., can solve problems such as damage to atomizers and couplers, failure of atomizers, poor contact of couplers, etc., and achieve economical benefits. , prolong service life and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

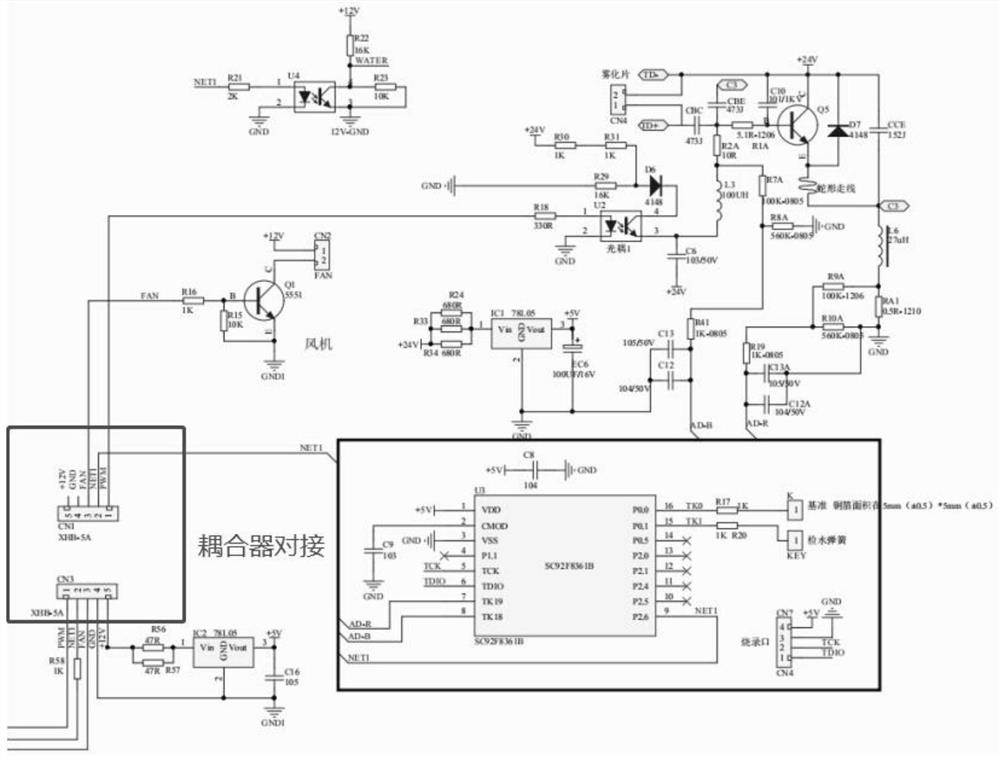

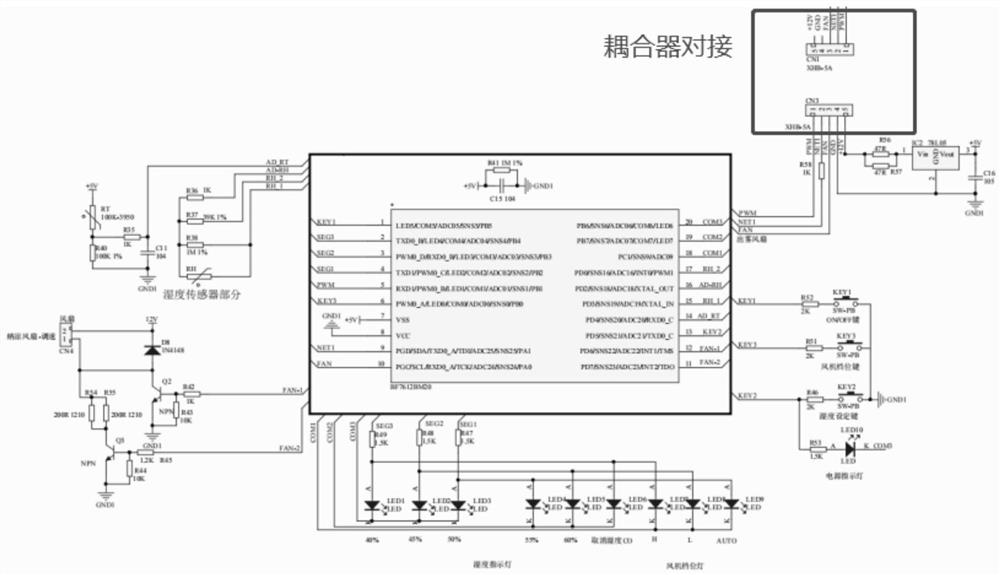

[0026] as attached figure 1 As shown, the present invention provides a technical solution: a protection circuit to prevent the electrolysis of the atomizing sheet and the coupler, including the control board 02 electrically connected to the fan 01 and the upper coupler 05, and one-to-one correspondence with the upper coupler 05 and coupling connection The lower coupler 04, the lower coupler 04 is connected with a large aluminum integrated board 06, the large aluminum integrated board 06 is connected with a fan 05 and a power line 07, and the power line 07 is connected with a power supply circuit, the The upper coupler 05 is provided with an upper coupling circuit, the lower coupler 04 is provided with a lower coupling circuit, the power supply circuit is electrically connected to the upper coupling circuit and the lower coupling circuit, and the upper coupling circuit is connected to the lower coupling circuit. There is no common ground between circuits.

Embodiment 2

[0028] The solution in Embodiment 1 will be further introduced in combination with specific working methods below, see the following description for details:

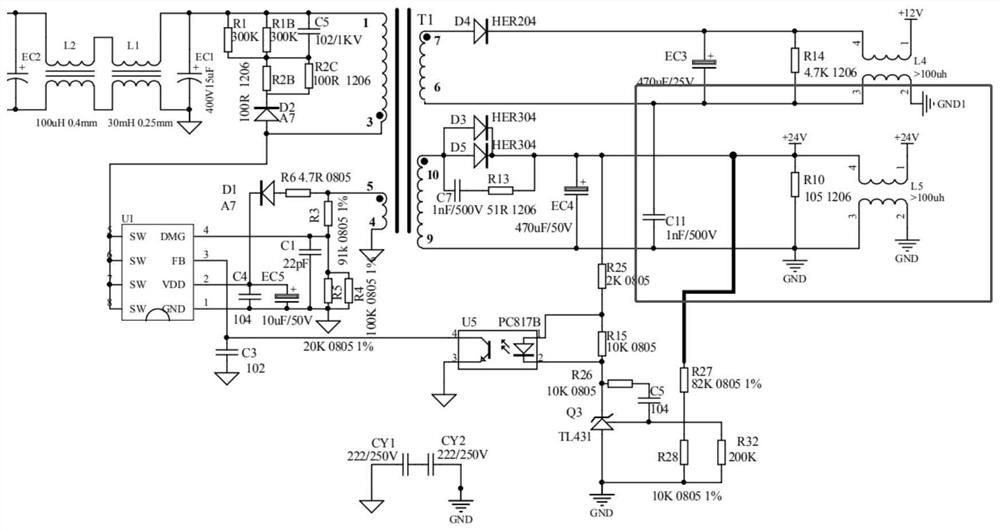

[0029] Such as figure 1 As shown, as a preferred embodiment, on the basis of the above method, further, the power supply circuit includes a power supply voltage U1, a capacitor C1 connected to the power supply voltage U1, a capacitor C4 and a capacitor C3, and a patch connected to the capacitor C4 Capacitor EC5 and diode D1, resistor R6 connected to diode D1, resistor R3 connected to resistor R6, resistor R4 and resistor R5, the power supply voltage U1 is also connected to diode D2, and diode D2 is connected to resistor R2B and resistor R2C , the resistor R2B is connected with a resistor R1, a resistor R1B and a capacitor C5, the supply voltage U1 is also connected with a transformer T1, and the transformer T1 is connected with a diode D3, a diode D4, a diode D5 and a capacitor C7, and the capacitor C7 is connected The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap