Writable screen

A screen and resin layer technology, applied in the field of writable screens, can solve the problems of reducing the projection function of hot spot effect and glare, and can not be said to be able to improve in a balanced manner, so as to prevent or reduce the hot spot effect and glare, improve rubbing the effect of elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

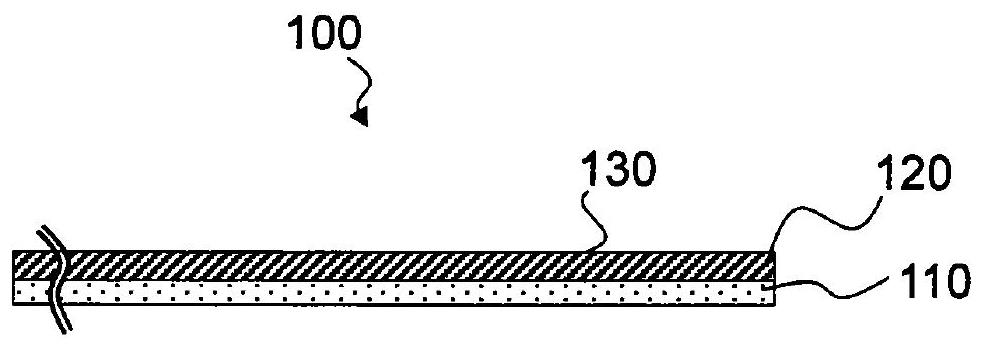

Image

Examples

Embodiment

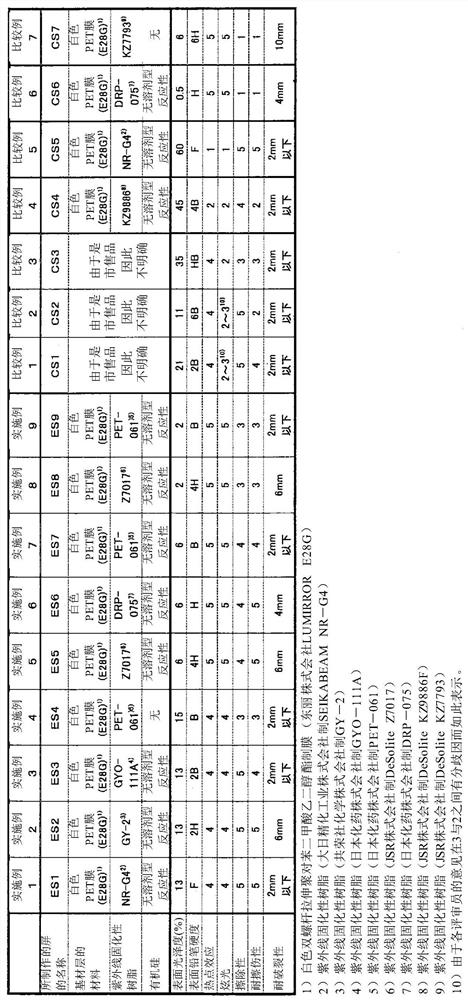

[0062] Hereinafter, although an Example is given and this invention is demonstrated in detail, this invention is not limited to these Examples.

[0063] (screen evaluation)

[0064] The following evaluation items were evaluated for the screens produced or obtained in the following Examples and Comparative Examples.

[0065] (1) Surface gloss

[0066] For the screens produced or obtained in Examples and Comparative Examples, the surface gloss (gloss, 60-degree specular gloss) of the outer surface of the resin layer was measured in accordance with JIS Z 8741 (1997).

[0067] (2) Surface pencil hardness

[0068] First, only the wooden shaft part of the pencil for a pencil hardness test (a set of 14 pencils of 6B to 6H with different hardnesses) was chipped off, and the core was exposed by 5 to 6 mm. Initially, the 6B pencil, which is the softest among them, was set in a pencil testing machine, and an angle of 45±1° was maintained under a state where a load of 750±10 g was appl...

reference example 1

[0100] (Reference example 1: Fabrication of sheet with texture for adjusting surface gloss)

[0101] The surface of 7 chrome-plated iron rollers is surface-finished by sandblasting to prepare 8 surface textures with a surface gloss of 0.5%, 2%, 6%, 13%, 15%, 45% or 60%. nip roller. These nip rolls were used to extrude the polypropylene resin into a sheet, thereby producing films with 0.5%, 2%, 6%, 13%, 15%, 45% % and 60% surface gloss for a textured sheet with a thickness of about 50 μm. In addition, the surface glossiness of the screens (ES1) to (ES9) of Examples 1 to 9 and the screens (CS4) to (CS7) of Comparative Examples 4 to 7 described later were compared with the respective textured sheets used. Surface gloss corresponds directly.

Embodiment 1

[0103] Add 1 part by weight of a solvent-free reactive silicone (X-22-174AS-X by Shin-Etsu Chemical Co., Ltd.) to 100 parts by weight of an ultraviolet curable resin (SEIKABEAM NR-G4 manufactured by Dainichi Seika Co., Ltd.) to obtain resin composition. Next, as a substrate layer, a white twin-screw stretched polyethylene terephthalate film (LUMIRROR E28G, manufactured by Toray Co., Ltd.) with a thickness of 125 μm and easy adhesion on both sides (anchor coating treatment) was used. This resin composition was coated on the top, and the sheet obtained in Reference Example 1 with a texture capable of providing a surface gloss of 13% was attached, pressurized with a pressure of 0.3 MPa, and irradiated with ultraviolet rays (irradiation conditions: 1700 mJ / cm 2 ), peeled the textured sheet, and produced a screen (ES1) in which a coating film (resin layer) with a thickness of 10 μm was formed on a white twin-screw stretched polyethylene terephthalate film. Table 1 shows the evalua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com