Working roll of temper mill and manufacturing method thereof

A manufacturing method and technology of work rolls, applied in the manufacture of tools, rolls, metal rolling, etc., can solve the problems of low production line efficiency, short machine time, etc., and achieve the effect of reducing manufacturing difficulty and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

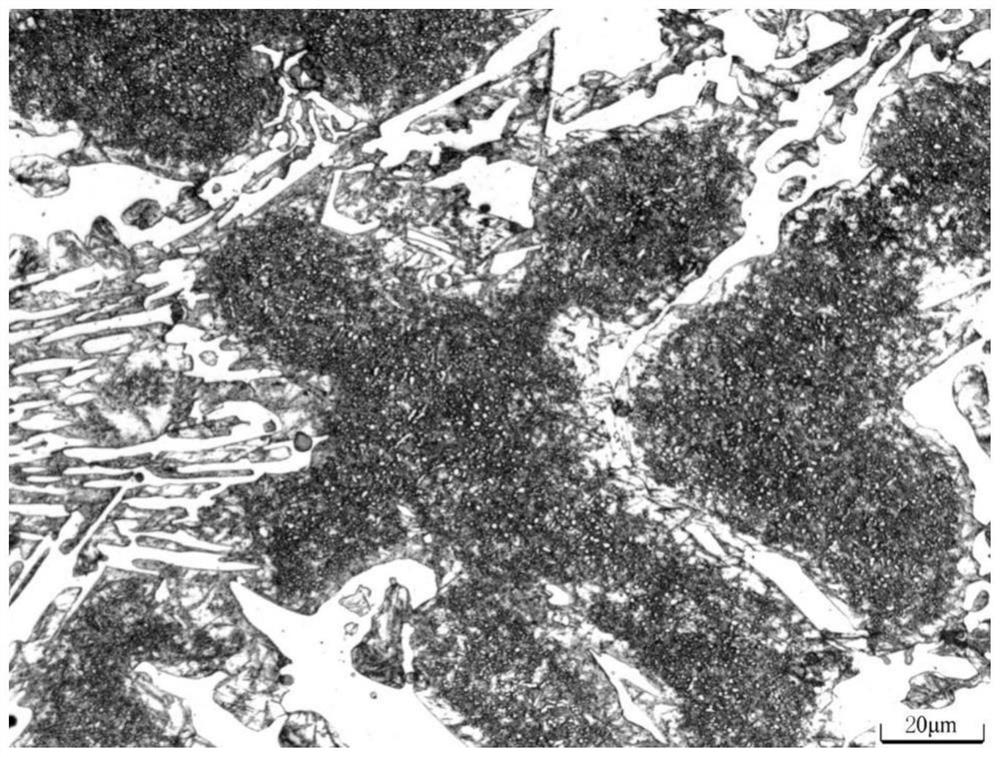

Image

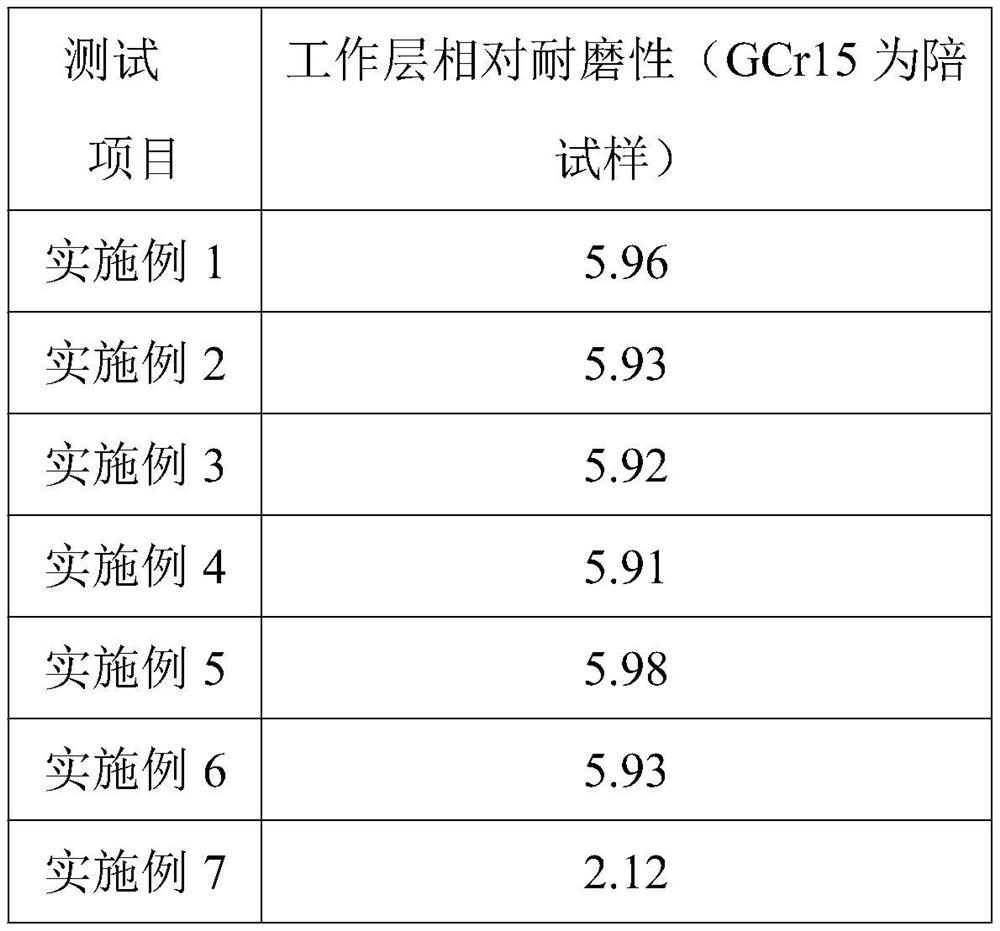

Examples

Embodiment 1

[0034] The roll sleeve of the work roll is made of steel scrap, ferronickel, ferrovanadium, ferrochromium, ferromolybdenum, and electrode powder, and is smelted in an intermediate frequency furnace to reach the design composition range: outer layer molten iron C2.33%, Si0.85%, Mn0 .9%, P0.05%, S0.06%, Cr20.56%, Ni0.98%, Mo0.85%, V1.01%, W0.5%, the balance is Fe; core molten iron C3.05% , Si1.36%, Mn0.95%, P0.06%, S0.07%, Cr0.03%, Ni0.12%, Mo0.3%, and the balance is Fe. The outer layer is smelted at a temperature of 1510°C. After the composition reaches the standard, the temperature is raised to 1530°C and then centrifugally poured. The molten steel melting temperature of the core is 1490°C, and the pouring temperature is 1510°C. The pouring water volume of the outer layer is 2.1t, and the pouring water volume of the core is 4.5t. 39 hours after pouring, open the box coldly, add 25mm in the axial direction and 12mm in the radial direction, heat at 980°C for 230min, cool in air ...

Embodiment 2

[0036] The roll sleeve of the work roll is made of steel scrap, ferronickel, ferrovanadium, ferrochromium, ferromolybdenum, and electrode powder, and is smelted in an intermediate frequency furnace to reach the design composition range: outer layer molten iron C2.33%, Si0.85%, Mn0 .9%, P0.05%, S0.06%, Cr20.56%, Ni0.98%, Mo0.85%, V1.01%, W0.5%, the balance is Fe; core molten iron C3.05% , Si1.36%, Mn0.95%, P0.06%, S0.07%, Cr0.03%, Ni0.12%, Mo0.3%, and the balance is Fe. The outer layer is smelted at a temperature of 1510°C. After the composition reaches the standard, the temperature is raised to 1530°C and then centrifugally poured. The molten steel melting temperature of the core is 1490°C, and the pouring temperature is 1510°C. The pouring water volume of the outer layer is 2.1t, and the pouring water volume of the core is 4.5t. 39 hours after pouring, open the box coldly, add 25mm in the axial direction and 12mm in the radial direction, heat at 980°C for 230min, cool in air ...

Embodiment 3

[0038]The roll sleeve of the work roll is made of steel scrap, ferronickel, ferrovanadium, ferrochromium, ferromolybdenum, and electrode powder, and is smelted in an intermediate frequency furnace to reach the design composition range: outer layer molten iron C2.81%, Si0.89%, Mn0 .92%, P0.06%, S0.07%, Cr22.36%, Ni1.32%, Mo0.99%, V1.03%, W0.45%, the balance is Fe; core molten iron C3.12% , Si1.31%, Mn0.91%, P0.05%, S0.06%, Cr0.01%, Ni0.11%, Mo0.2%, and the balance is Fe. The outer layer is smelted at a temperature of 1520°C. After the composition reaches the standard, the temperature is raised to 1535°C and then centrifugally poured out of the furnace. The molten steel melting temperature of the core is 1485°C, and the pouring temperature is 1505°C. The pouring water volume of the outer layer is 1.9t, and the pouring water volume of the core is 4.3t. 35 hours after pouring, open the box coldly, add 23mm in the axial direction and 11mm in the radial diameter direction, heat at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com