Metal coiled material slitting device and using method thereof

A technology for metal coils and metal sheets, applied in shearing devices, accessories of shearing machines, coiling strips, etc. The effect of improving multi-applicability and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

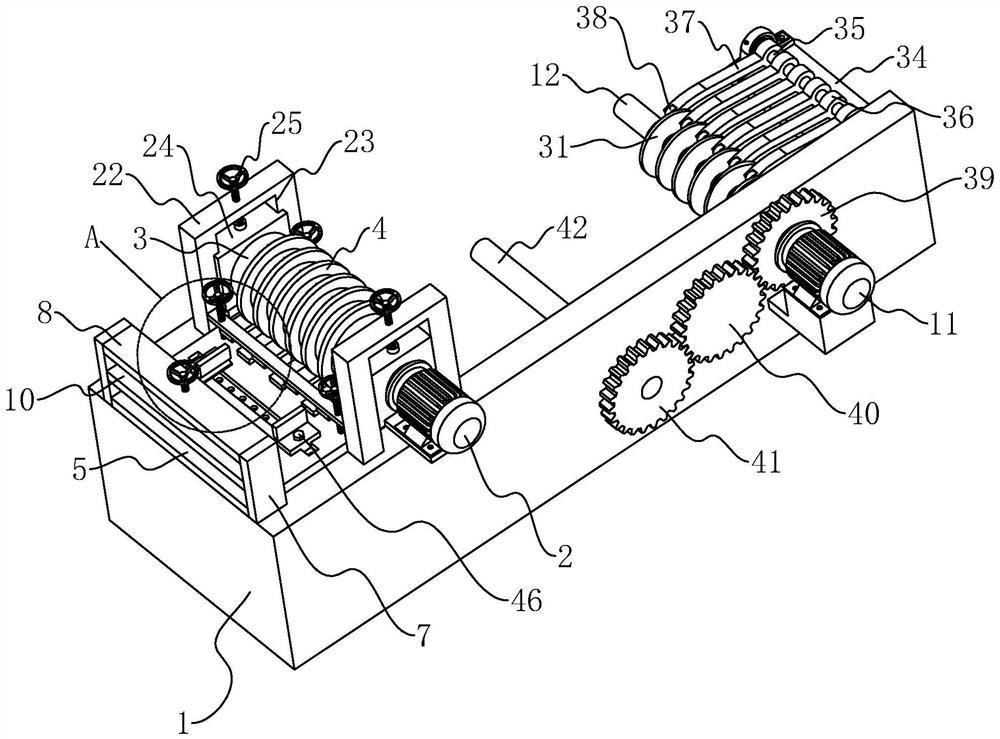

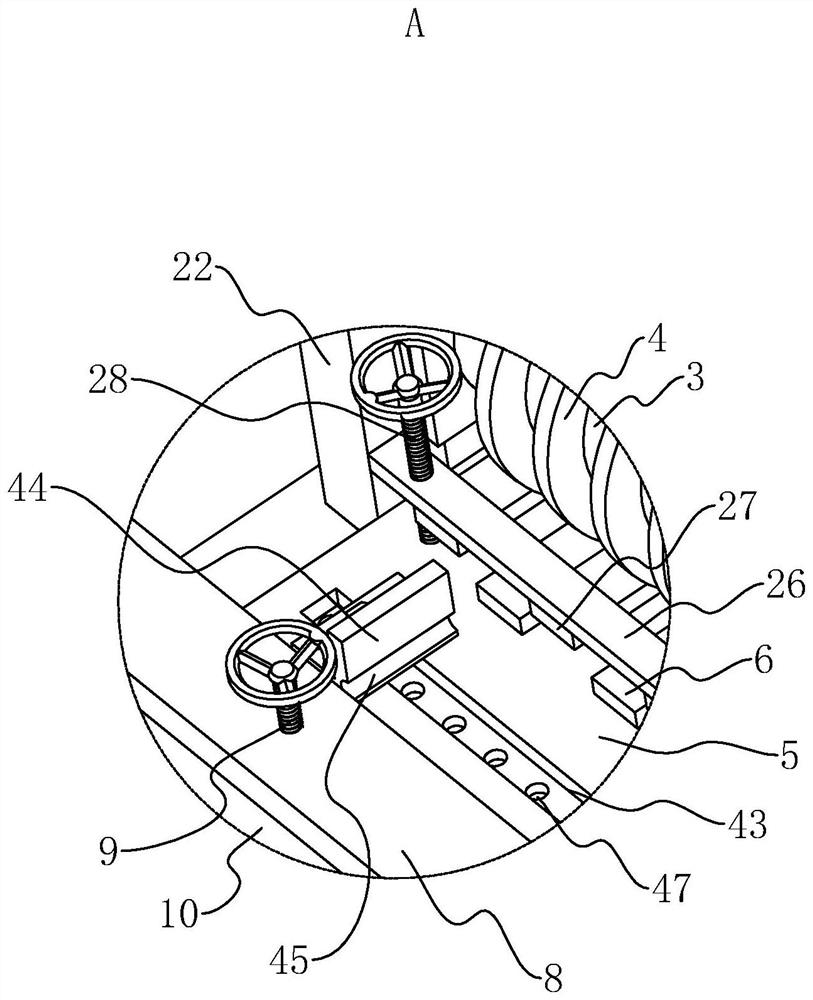

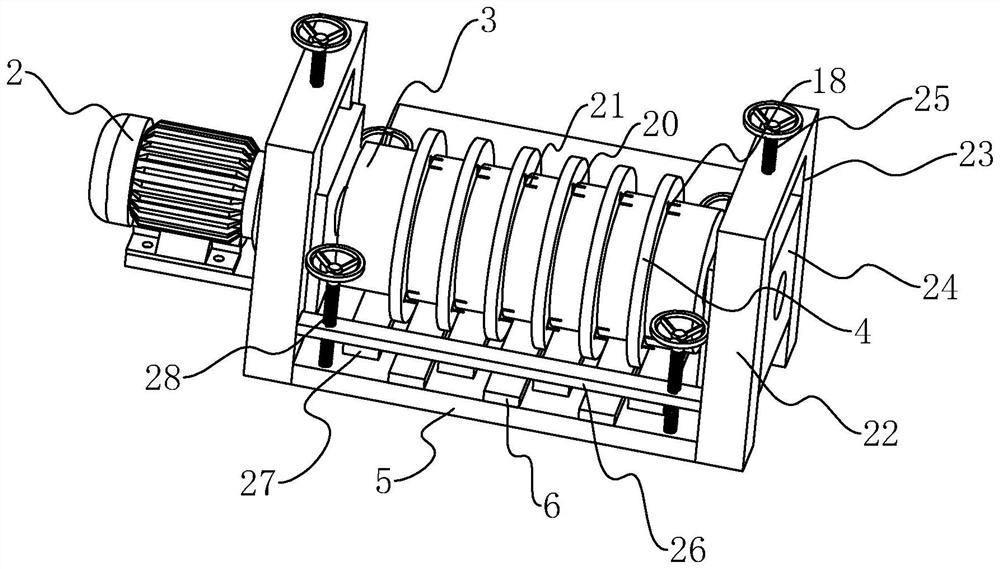

[0037] refer to figure 1 with figure 2, a metal coil cutting device, including a frame 1, the frame 1 is made of stainless steel, has a certain rigidity and load-bearing capacity. The frame 1 is fixed with a conveyor plate 5, and the frame 1 is fixed with columns 7 parallel to each other. A fixed plate 8 is fixedly connected between the two columns 7. The fixed plate 8 is threadedly connected with a first screw rod 9, and the first screw rod 9 passes through the The fixed plate 8 is rotatably connected with a pressing plate 10 , and there is a gap between the pressing plate 10 and the conveying plate 5 . When the metal coil cutting device is in use, the metal sheet is placed on the conveying plate 5 from the column 7, and the metal sheet is passed through the gap between the pressing plate 10 and the conveying plate 5. The pressing plate 10 ensures that the metal sheet is cut Keep it flat.

[0038] refer to figure 1 with figure 2 , the upper end of the first screw 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com