Machining residue cleaning and transferring device for laser-induced forming machine tool

A technology of laser induction and transfer device, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as abnormal operation and use of equipment, distortion of sensitive positions of equipment, hidden dangers of waste transfer safety, etc., to avoid moving speed. Too fast, stable rotation effect, avoid overheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

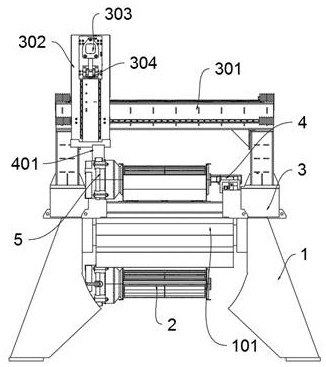

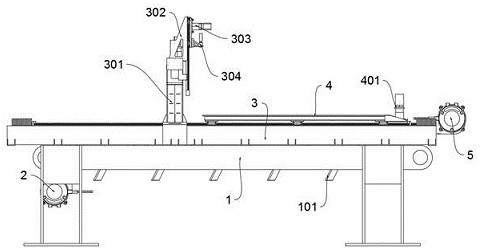

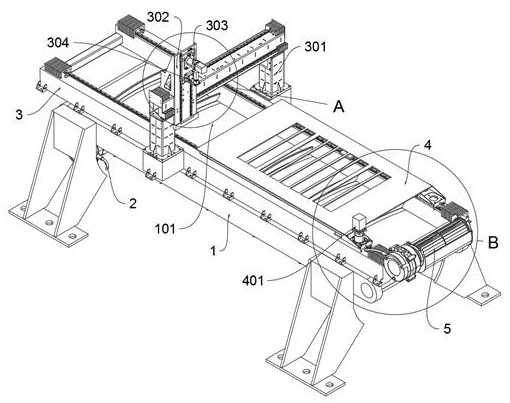

[0044]as attached figure 1 To attach Figure 8 Shown:

[0045] The present invention provides a laser-induced forming machine tool processing residue cleaning and transfer device, including: a frame body 1;

[0046] The four corners of the bottom of the frame body 1 are provided with supporting legs, and the front and rear ends of the frame body 1 are provided with rotating rods; the middle position of the two supporting legs at the rear end of the frame body 1 is fixedly connected with the driving part A2; the frame body 1 includes: a conveyor belt Circle 101, the outer end of the conveyor belt circle 101 is provided with twelve arc panels, the distance between each adjacent two arc panels is the same, and each arc panel is inclined, and the conveyor belt circle 101 passes through the rotation rod at both ends of the frame body 1. Cooperate and rotate to be connected at the upper end position of support body 1.

[0047] Wherein, a motor is arranged on the left side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com