Metal-based ceramic glove mold and preparation method thereof

A metal-based, glove-based technology, applied in household appliances, other household appliances, household components, etc., to achieve the effect of cost reduction, low cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

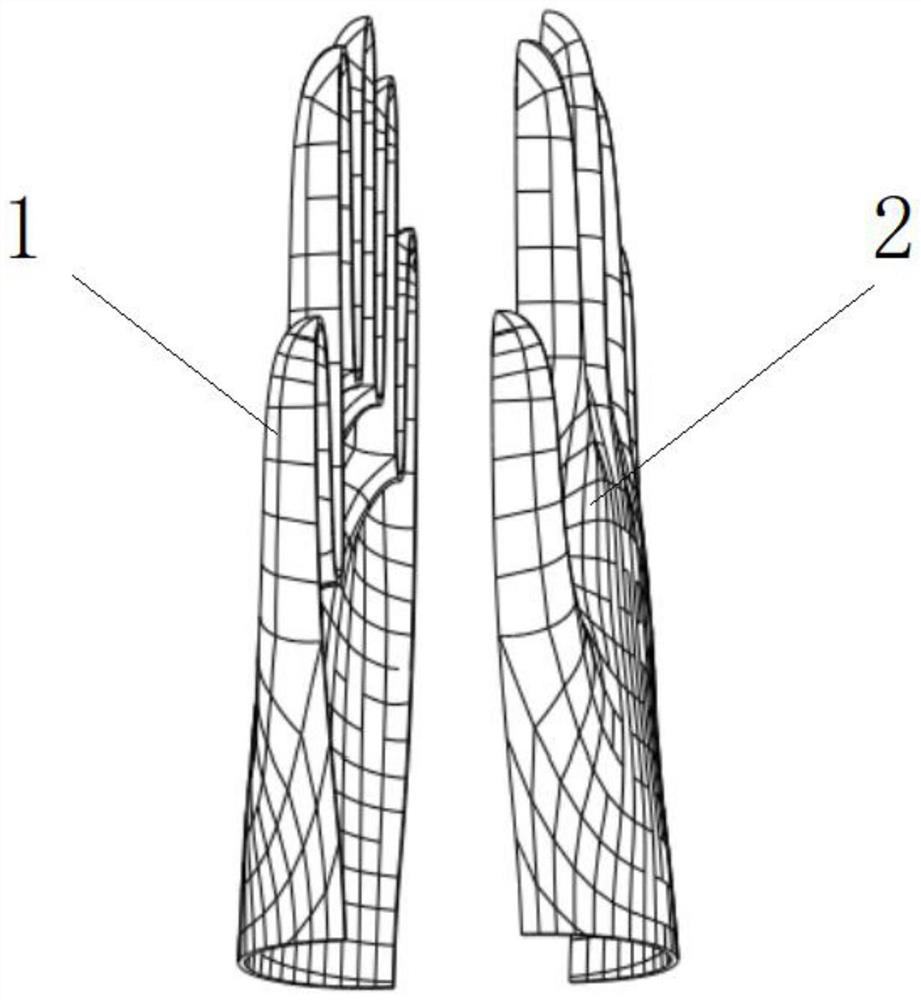

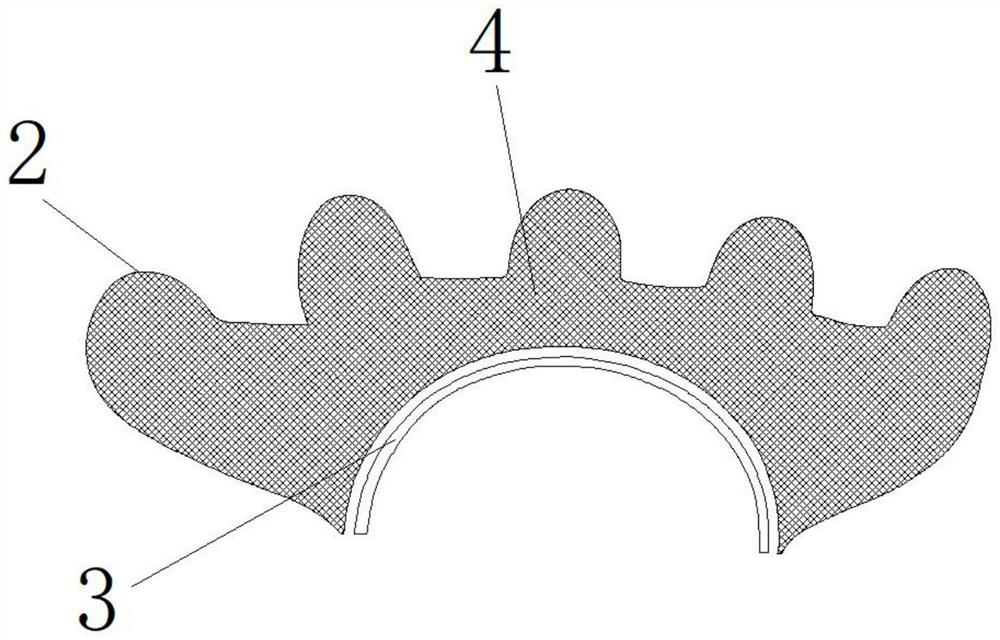

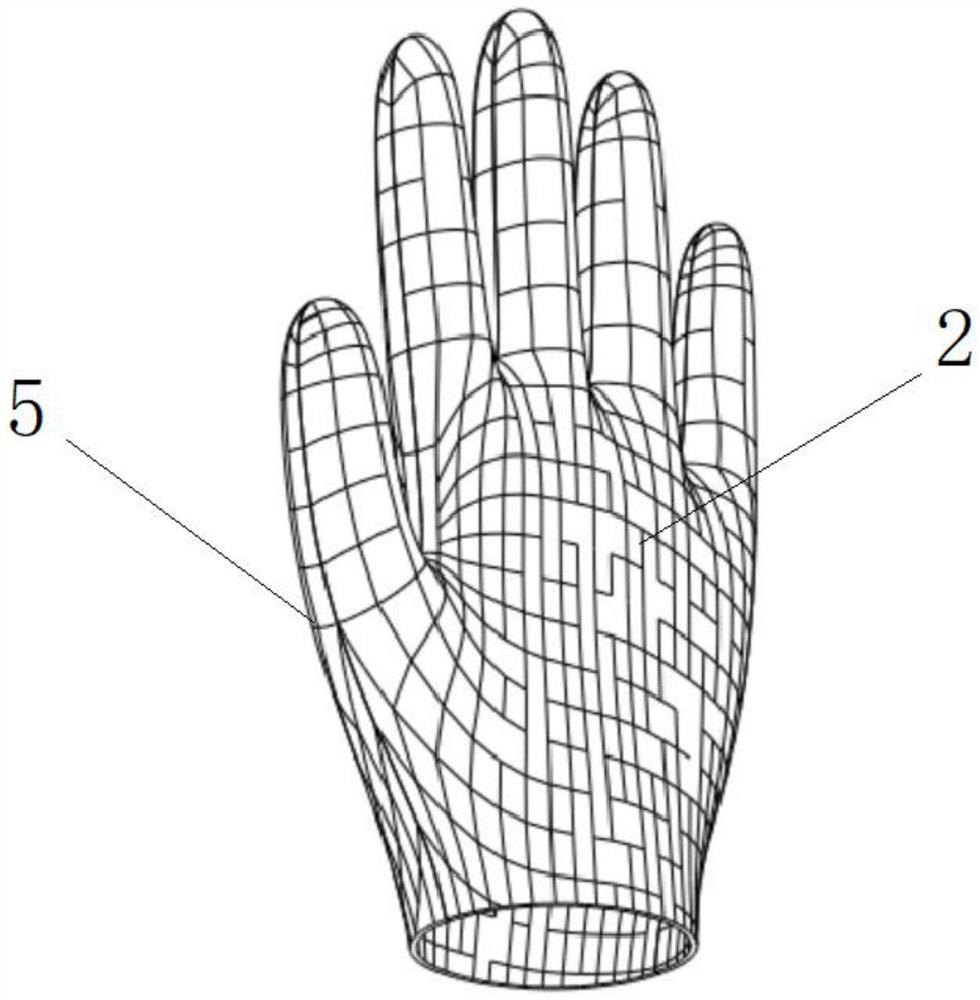

[0026] see Figure 1-4 , a metal-based ceramic glove mold, including an upper mold 1 and a lower mold 2, the upper mold 1 and the lower mold 2 include a metal plate 3 and an enamel layer 4, the metal plate 3 is made of aluminum alloy, the upper mold Die 1 and lower die 2 are fixed by brazing welding.

[0027] Wherein, the metal plate 3 is punched into a glove shape, and the thickness of the metal plate 3 is 1-5 mm.

[0028] Wherein, the enamel layer 4 is attached to the surface of the metal plate 3 by spraying, and the thickness of the enamel layer 4 is 2-5 mm.

[0029] A method for preparing a metal-based ceramic glove mold, comprising the following steps:

[0030] Step 1: Select the metal plate 3 and use a punching machine to stamp it into a glove shape, such as Figure 4 shown;

[0031] Step 2: Weld and fix the two half-face molds stamped and formed in Step 1 by vacuum brazing;

[0032] Step 3: Grind and polish the surface of the welded mold to form a complete metal han...

Embodiment 2

[0036] see Figure 1-4 , a metal-based ceramic glove mold, including an upper mold 1 and a lower mold 2, the upper mold 1 and the lower mold 2 include a metal plate 3 and an enamel layer 4, and the metal plate 3 is made of aluminum alloy Composite alloy material, the upper mold 1 and the lower mold 2 are fixed by brazing.

[0037] Wherein, the metal plate 3 is punched into a glove shape, and the thickness of the metal plate 3 is 1-5mm.

[0038] Wherein, the enamel layer 4 is attached to the surface of the metal plate 3 by spraying, and the thickness of the enamel layer 4 is 2-5mm.

[0039] A method for preparing a metal-based ceramic glove mold, comprising the following steps:

[0040] Step 1: Select the metal plate 3 and use a punching machine to stamp it into a glove shape, such as Figure 4 shown;

[0041] Step 2: Weld and fix the two half-face molds stamped and formed in Step 1 by vacuum brazing;

[0042] Step 3: Grind and polish the surface of the welded mold to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com