Blast furnace gas injection control system and control method

A control system and coke oven gas technology, applied in the field of blast furnace gas injection to achieve the effect of reducing carbon emissions and ensuring system safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

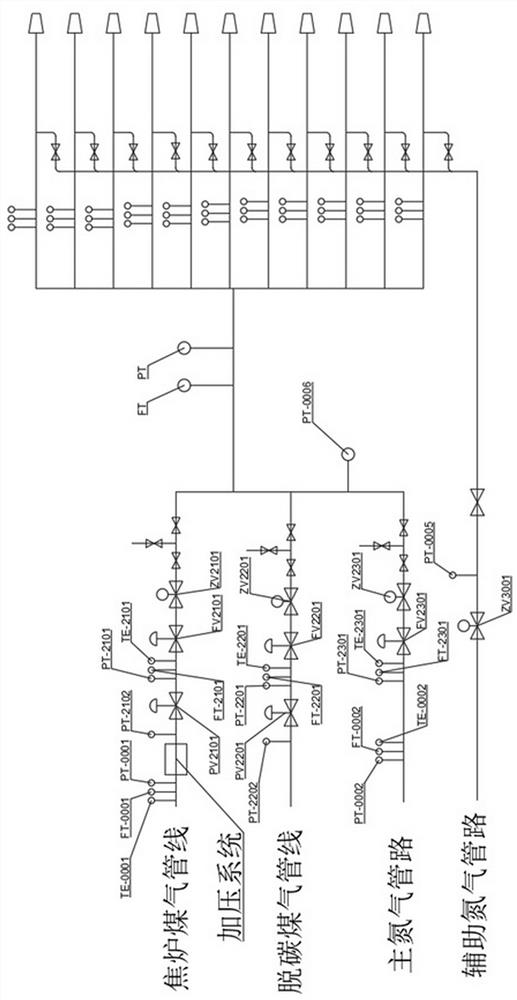

[0053] Such as figure 1 The blast furnace gas injection system includes a coke oven gas pipeline, a decarburization gas pipeline and a protective nitrogen pipeline.

[0054] The coke oven gas pipeline and the decarburization gas pipeline are connected to the same main gas pipeline, and the main gas pipeline is distributed to the nozzle of the blast furnace gas injection port, and the gas is injected into the blast furnace through the nozzle.

[0055]The protective nitrogen gas pipeline has two pipelines, one of which is connected to the same main gas pipeline as the coke oven gas pipeline and the decarbonized gas pipeline, and the protective nitrogen gas enters the main gas pipeline together with the coke oven gas and decarbonized gas, and is controlled by the main gas pipeline. The gas pipeline is distributed to the nozzle and sprayed into the blast furnace.

[0056] The protective nitrogen pipeline includes a main nitrogen pipeline directly connected to the main gas pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com