Runner plate structure

A flow channel plate and pipeline technology, applied in the valve shell structure, functional valve type, lift valve and other directions, can solve the problems of high cost of embedded check valve, leakage of embedded check valve, complicated structure of flow channel plate, etc. Achieve a wide range of applications and scenes, reduce weight, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

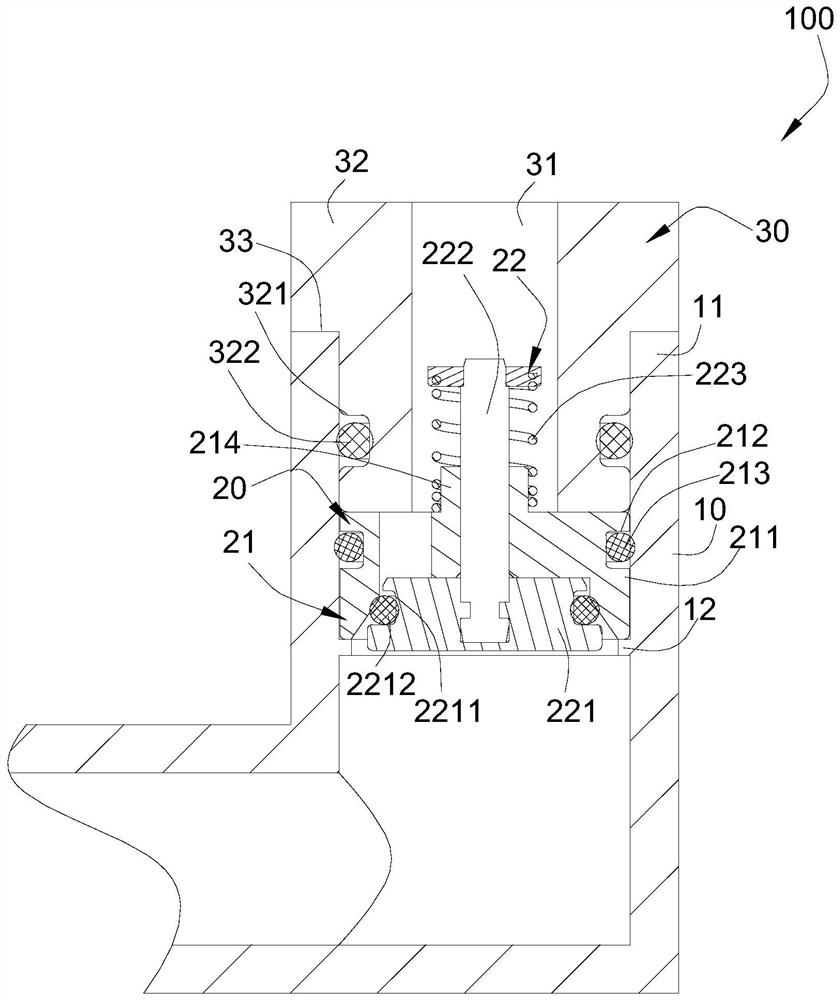

[0064] see figure 1 , one end of the installation body 211 abuts against the end of the sealing unit 30 away from the inlet, and the other end of the installation body 211 abuts against the resisting platform 12, so that no additional stoppers are required to fix the installation body 211, making the structure simple and stable, Space and cost are saved; at the same time, the valve body assembly 21 is firmly limited at a specified position through the limit on both sides of the installation body 211, preventing it from shifting and leaking, which affects the realization of device functions.

[0065] One end of the connection body 214 is connected to the installation body 211 , and the other end of the connection body 214 at least partially extends into the flow hole 31 , and both of them fix and limit the straight-through check valve 20 and the flow channel plate body 10 .

Embodiment 2

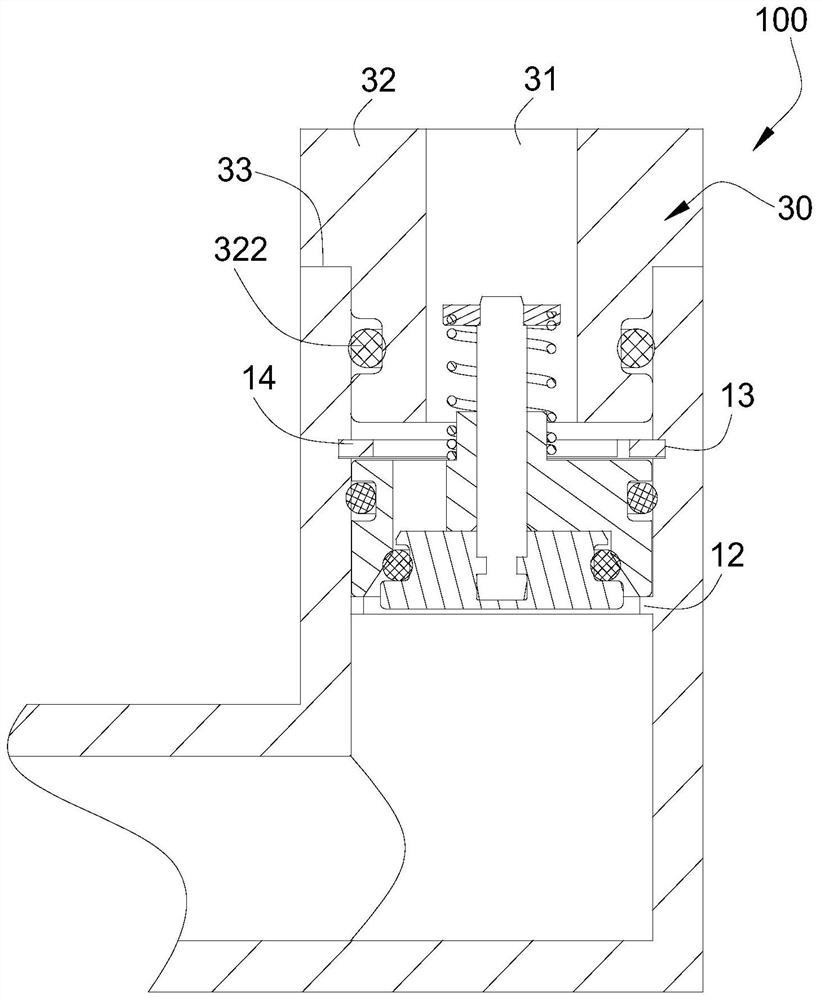

[0067] see figure 2 A groove 13 is formed on the inner wall of the flow channel plate body 10 in the circumferential direction, and the groove 13 is located between the sealing unit 30 and the mounting body 211 . The groove 13 is provided with a snap spring 14, and the snap spring 14 is sleeved outside the part of the connecting body 214. Through the circumferential clamping effect of the snap spring 14 on the mounting body 211, the position-limiting firmness of the mounting body 211 is further enhanced, thereby The overall structural stability of the valve body assembly 21 and even the straight-through check valve 20 is enhanced.

[0068] It can be understood that in other embodiments, other limiting parts can be provided between the runner plate body 10 and the installation body 211, as long as the installation body 211 and the runner plate body 10 can be fixed and limited. It is limited to the clip spring 14 described in this embodiment.

[0069] In this application, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com