Machining process and machining device for double-end-face coated bearing

A processing technology, double-end face technology, applied in the direction of grinding workpiece support, grinding frame, grinding machine bed, etc., can solve the problems of machining surface error, large measurement accumulation error, difference not greater than 0.005mm, etc., to eliminate Positioning plane difference and machining plane error, meeting the requirements of parts matching, and the effect of scientific process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The processing technology of the double-end coated bearing of this embodiment includes the following steps:

[0032] 1) Fit the butt surface on the first bearing and the butt surface on the second bearing so that the first bearing and the second bearing are combined; use two clamping clips 1, and fit one of the clamping clips 1 Align and insert the positioning surface with the positioning groove on the first bearing, align and insert the positioning surface of the other clamping clip 1 with the positioning groove on the second bearing, so that the first bearing and the second bearing The relative position between them is fixed on the same reference plane, and the first coated surface of the first bearing and the first coated surface of the second bearing are ground using a grinding tool, so that the first coated surface of the first bearing and the second coated surface The first coated surface of the bearing is in the same plane;

[0033] 2) Turn the first bearing and...

Embodiment 2

[0041] The processing technology of the double-end coated bearing of this embodiment, on the basis of embodiment 1, it also includes the following steps:

[0042] 3) Measure the flatness, parallelism, and height difference of the double-end surfaces of the first bearing and the second bearing. After the measurement is completed, remove the first bearing and the second bearing from the reference plane; disassemble the first bearing The clamping clip 1 on the top and the clipping clip 1 on the second bearing complete the double-end coating of the first bearing and the second bearing.

Embodiment 3

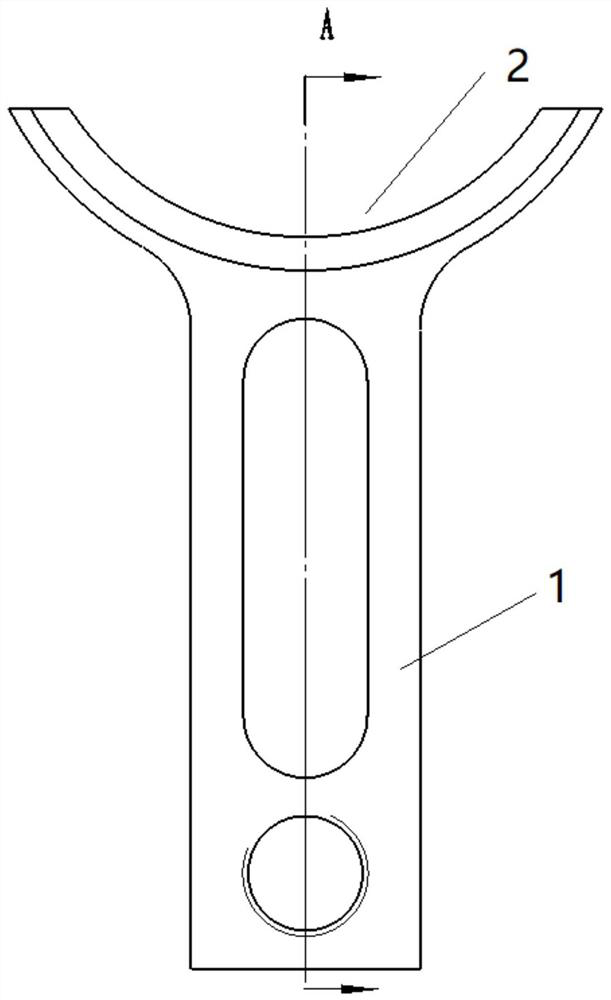

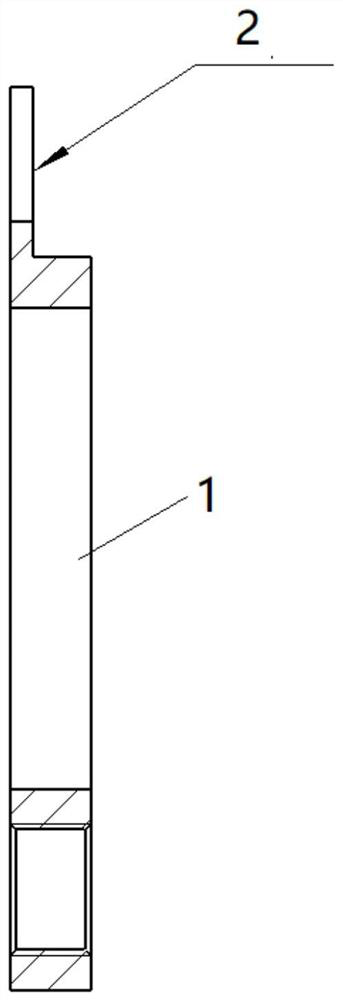

[0044] see Figure 1-Figure 3, the processing device of the double-end surface coated bearing in this embodiment, the processing device is formed based on the processing technology of embodiment 1 or embodiment 2, which includes clamping clip 1 and fixed base 3, clamping clip 1 includes a positioning part and a handle part, the handle part is a handle rod, the positioning part is an arc-shaped structure, and a positioning surface 2 is arranged on the inner side of the arc-shaped structure, and the positioning surface 2 is an L-shaped structure in cross section, and the positioning surface The shape of 2 coincides with the shape of the positioning groove on the first bearing / second bearing, and the handle part is fixedly connected to the outside of the arc-shaped structure and arranged along the radial direction of the arc-shaped structure.

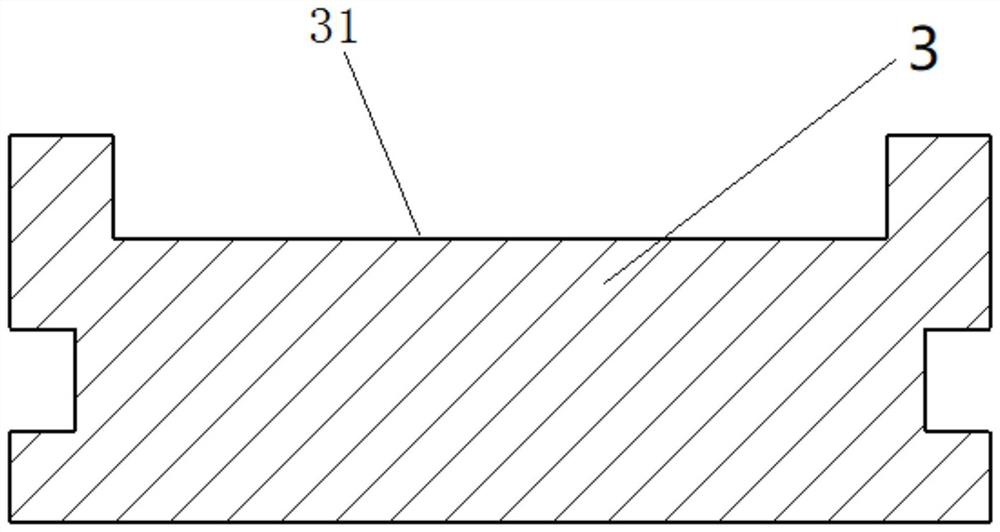

[0045] The top of the fixed base 3 is provided with a reference groove, and the bottom wall of the reference groove is a positioning refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com