Automatic imitation copper wire drawing machine based on multiple machine heads

A multi-head and wire drawing machine technology, which is applied to the parts of grinding machine tools, grinding racks, grinding drive devices, etc., can solve the problems of choking paint, low work efficiency, and different wire drawing effects, etc. Achieve the effect of reducing labor intensity and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

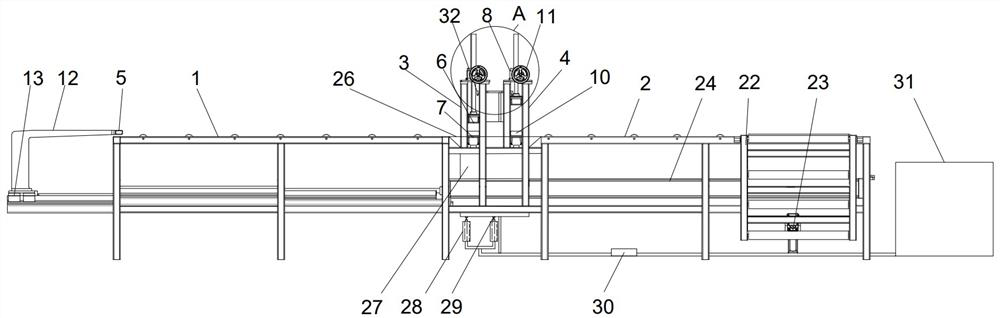

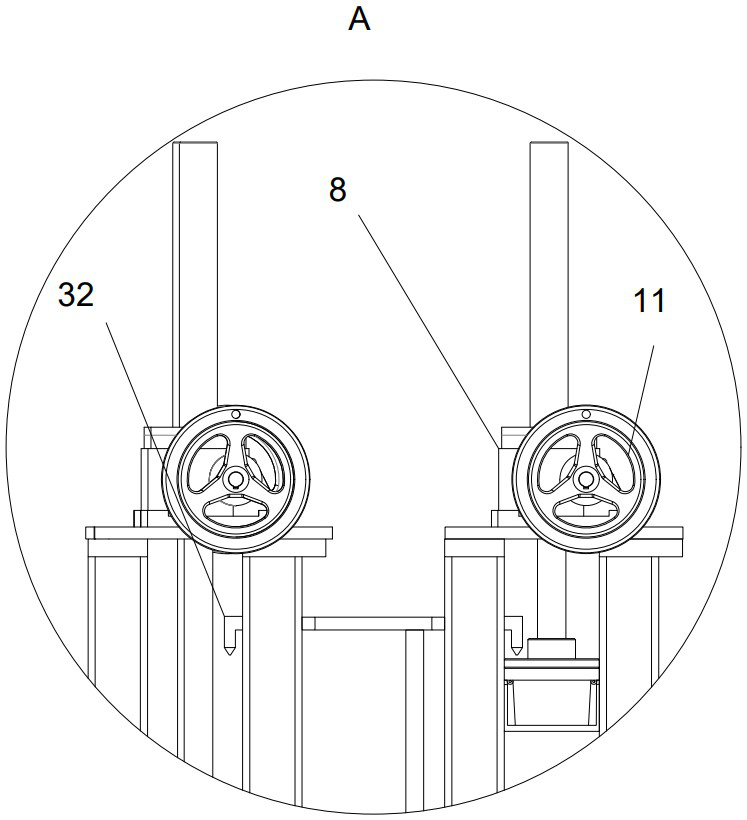

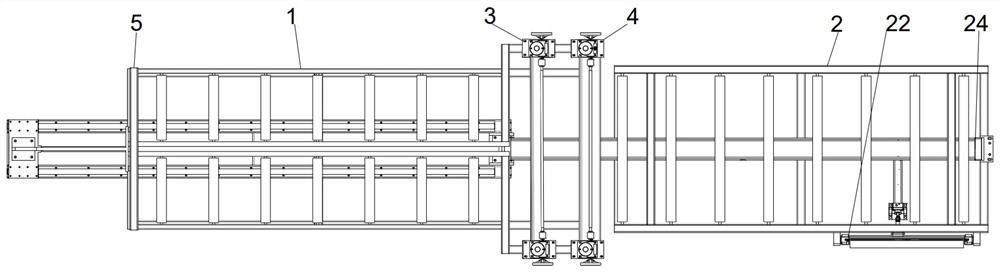

[0031] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 8 , the present embodiment provides a kind of automatic imitation copper wire drawing machine based on multi-head, comprising feeding rack 1, discharging rack 2 and scouring pad 25 for wire drawing, one end of the feeding port of the feeding rack 1 A push plate 5 that can move back and forth in the feed frame 1 to push the door panel is provided. A channel for the reciprocating movement of the push plate 5 is provided in the middle of the feed frame 1. The channel divides the feed frame 1 into two strokes symmetrically. The same door panel placement area, two wire drawing heads are arranged between the feed frame 1 and the discharge frame 2, respectively the first wire drawing head 3 and the second wire drawing head 4, the first wire drawing head 3 Connect with one end of the second wire drawing head 4 body, the other end of the first wire drawing head 3 and the second wire dr...

Embodiment 2

[0045] refer to Figure 7 , the difference from Example 1 is:

[0046] Described driving device comprises drive motor 14, connecting plate 12, belt 15 and two pulleys 16, and two pulleys 16 are respectively arranged on the crossbeam of feeding frame 1 feed inlet and discharge outlet, and described belt 15 is sleeved on On two belt pulleys 16, described driving motor 14 is arranged on the feeding mouth one end of feeding rack 1, and the rotating shaft of described driving motor 14 is connected with the belt pulley 16 of feeding mouth rotatably, and described feeding rack 1 is provided with Guide rail, a slide block 13 is arranged in the guide rail, one end of the connecting plate 12 is detachably mounted on the slide block 13 , and the push plate 5 is detachably mounted on the other end of the connecting plate 12 .

[0047] The driving motor 14 drives the belt pulley 16 to drive the belt 15 to rotate, so that the connecting plate 12 on the belt 15 drives the push plate 5 to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com