Robot breaking-off control method for liquid crystal glass substrate

A liquid crystal glass substrate and robot technology, applied in the field of automation, can solve problems such as equipment failure, low yield rate, easy breakage, etc., and achieve the effects of reducing jitter, improving stability and success rate, and ensuring flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] First, determine the reference coordinate system when the motion control program controls the robot movement;

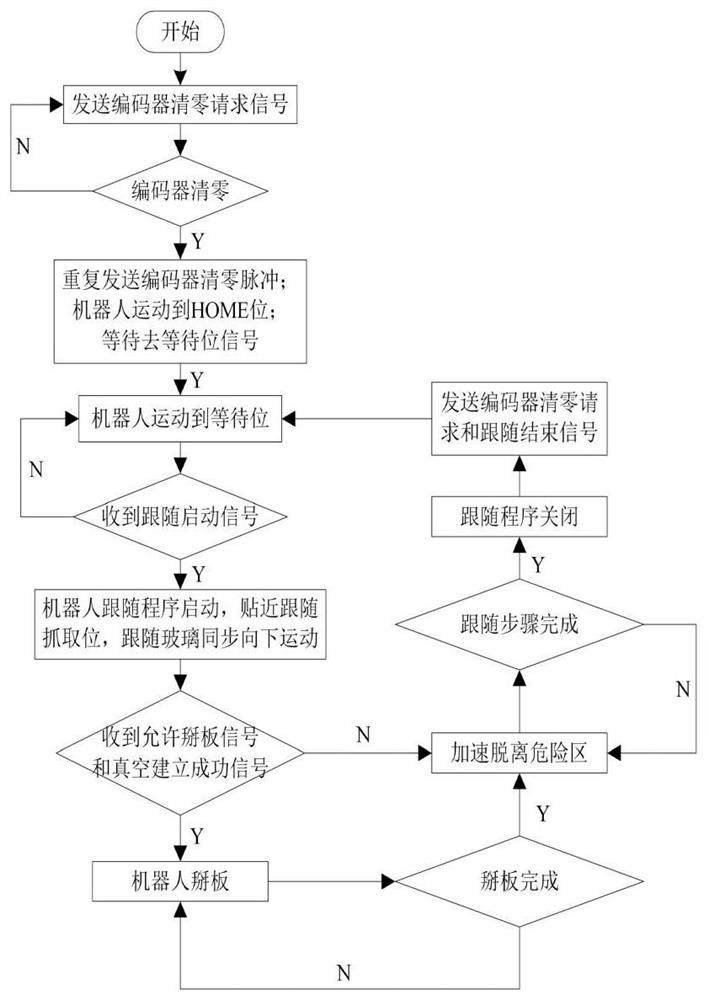

[0042] The board breaking robot enters the HOME position, continuously clears the position encoder, and waits for the input signal of the waiting position. The board breaking robot receives the signal to go to the waiting position and moves to the waiting position. After receiving the de-approach signal, the motion control program controls the robot's actions.

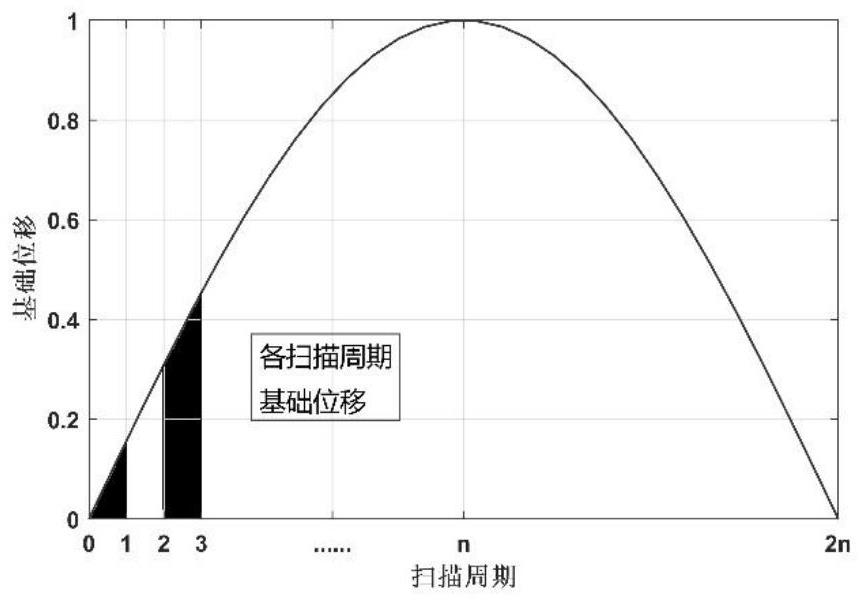

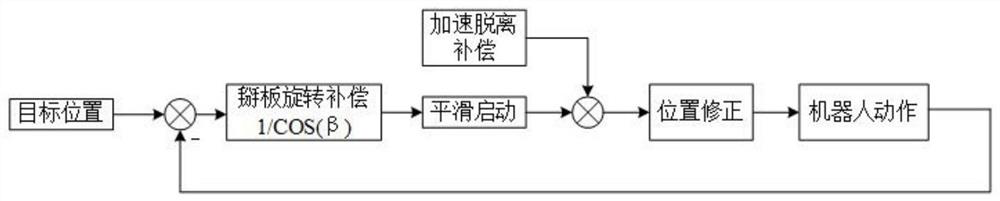

[0043] 1. The motion control program controls the breaker robot in the Z direction, and controls the movement of the breaker robot by a smooth motion control method with a fixed distance between the known initial position and the target position. The fixed displacement in each scan cycle is as figure 2 shown. Let the extension distance S between the waiting position and the approaching position in the positive direction of the Z axis. Using the smooth characteristic of the sinusoidal function curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com