Refrigeration type liquid cooling heat dissipation closed LCD (Liquid Crystal Display) projection ray machine

A liquid-cooled heat dissipation, projector light machine technology, applied in optics, instruments, projection devices, etc., can solve the problem of weak heat dissipation capacity of fully enclosed light machines, and achieve the effect of improving the scope of application, reducing operating noise, and avoiding excessive temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical solutions and advantages of the present invention clearer, the present invention and its beneficial effects will be further described in detail below in conjunction with specific embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

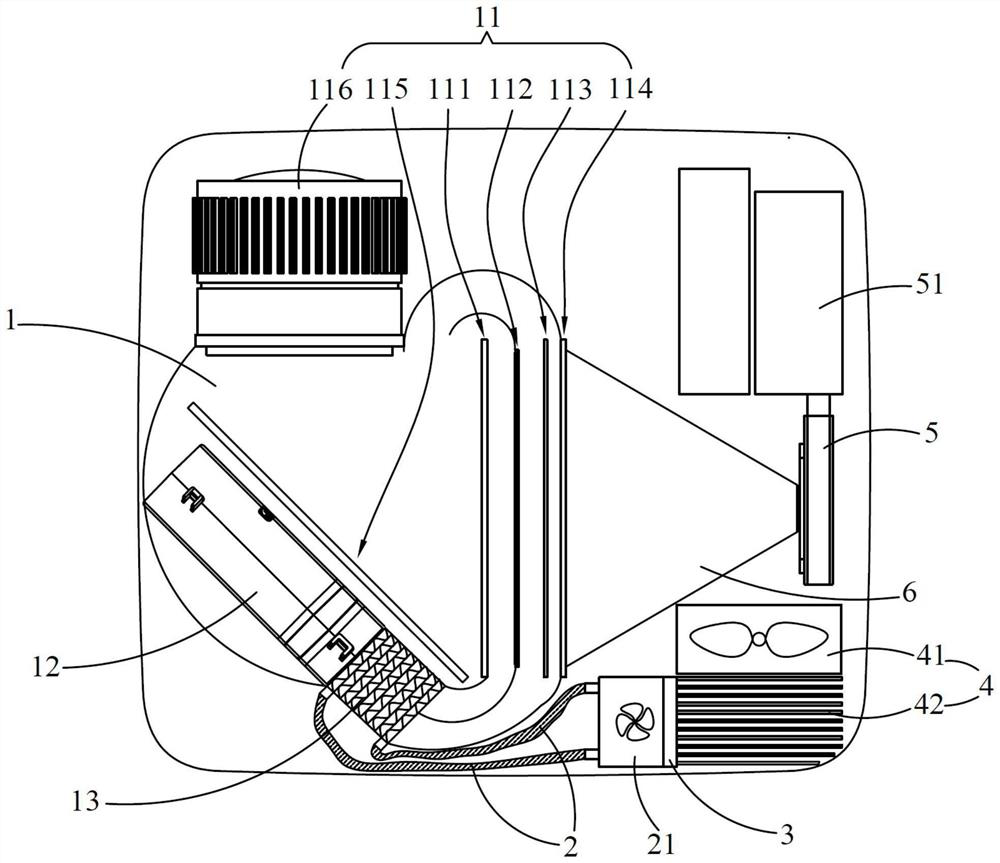

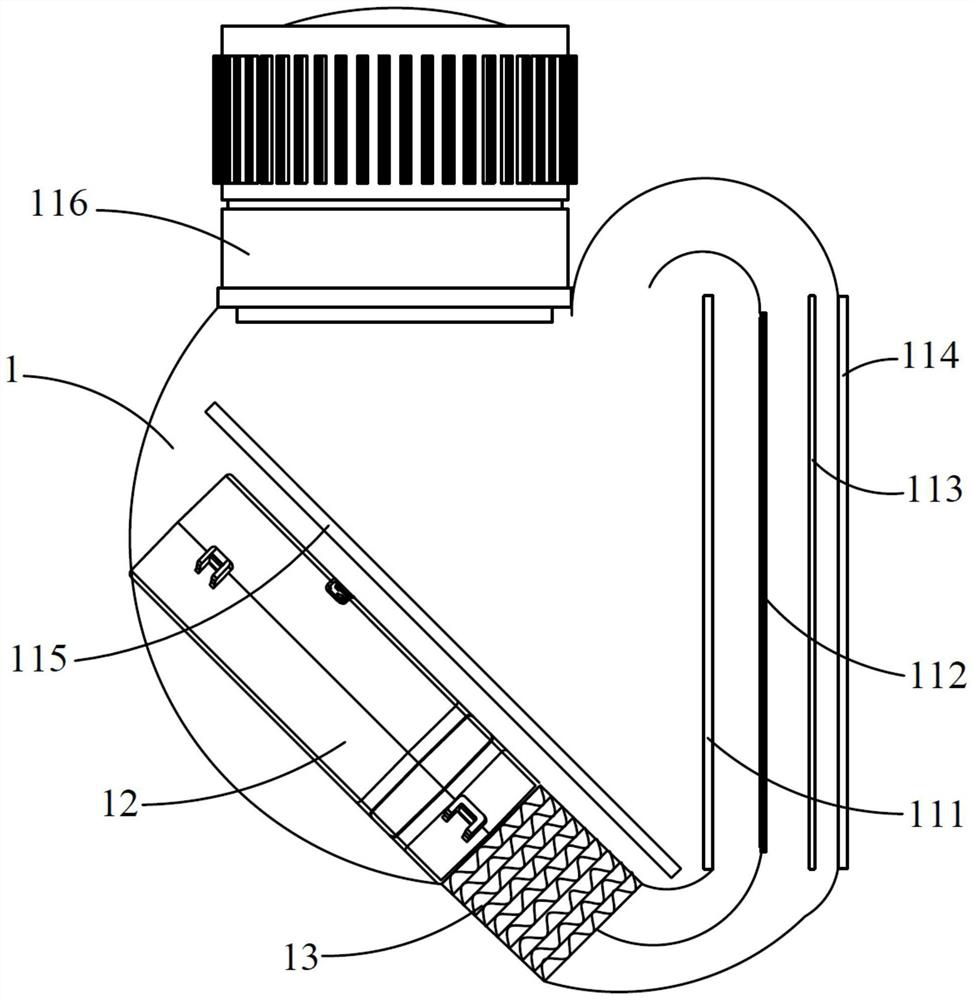

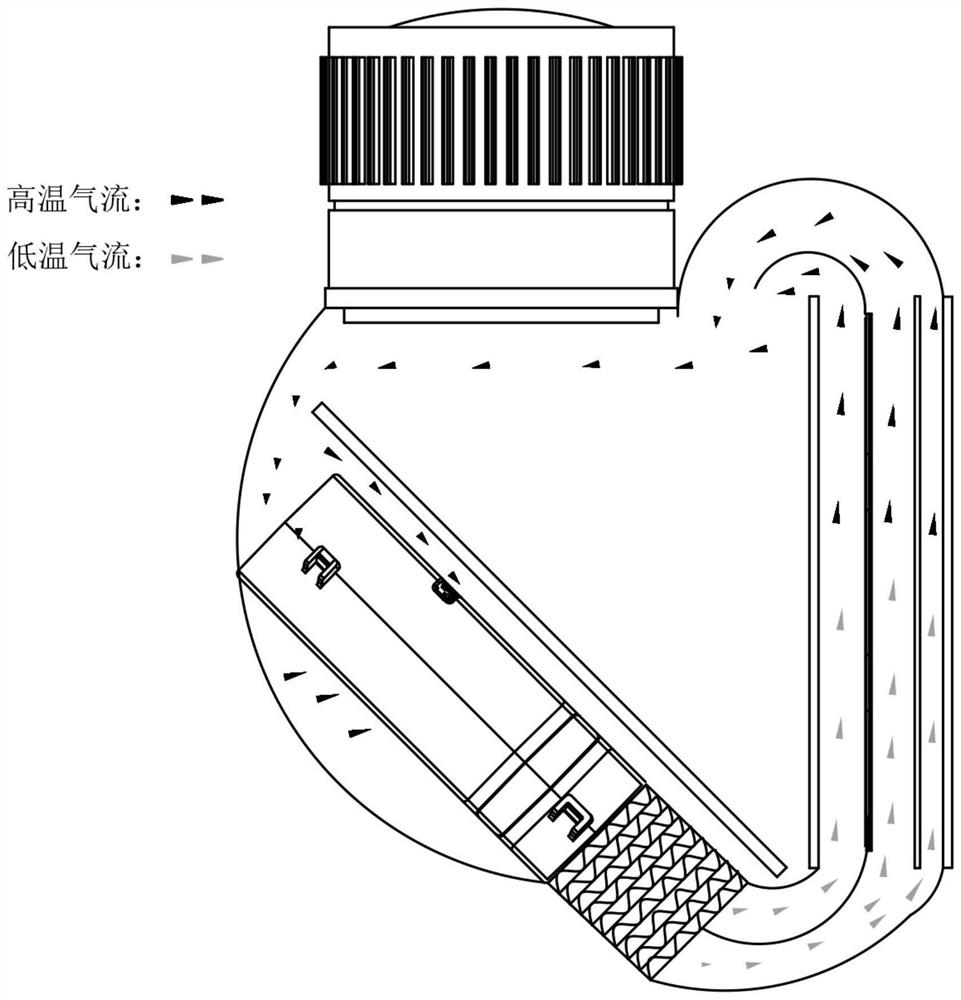

[0034] Such as Figure 1 to Figure 5 As shown, the airtight liquid-cooled and heat-dissipating LCD projector includes an internally sealed cavity 1, a heat dissipation pipe 2 outside the cavity, and a cooling plate 3. The cavity 1 is provided with an optical component 11, an intra-cavity circulating fan 12 and a cavity Inner heat exchanger 13, the optical assembly 11 includes an LCD liquid crystal screen 112, the heat dissipation pipe 2 outside the cavity and the cooling plate 3 are arranged outside the cavity 1, and the inner cavity heat exchanger 13 is arranged at the air outlet of the inner cavity circulating fan 12, and the inner cavity heat exchange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com