Method for constructing three-dimensional model of overhead line system based on suspension points

A 3D model and construction method technology, applied in special data processing applications, geometric CAD, etc., can solve problems such as low fault tolerance rate and large underlying model volume, reduce the number of component models, increase the scope of application, and reduce hardware requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] To enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

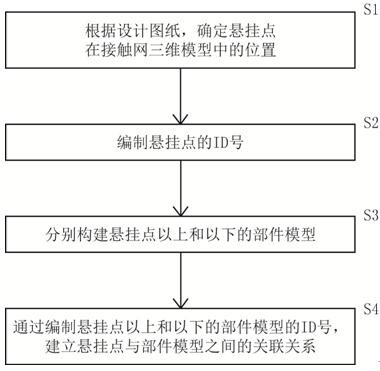

[0024] Embodiments of the present invention provides a three-dimensional model construction method based on a catenary based on a hanging point, such as Figure 1 shown, which includes the following steps:

[0025] S1: According to the design drawings, determine the position of the hanging point in the catenary 3D model.

[0026] S2: Compile the ID number of the suspension point, and the ID number of the hanging point includes the line, station area, line, kilometer mark, pillar / hanging column number and hanging point number in turn. Hanging point numbers are specified according to the design drawings in the order of traditional design methods.

[0027] S3: Construct the component model above the suspension point and below the suspension point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com