Rotary tillage seeder

The technology of a seeder and a rotary tiller is applied in the field of agricultural machinery, which can solve the problems of poor ventilation and light transmission of wheat plants, inability to put fertilizers evenly, and unfavorable fertilizer storage in the fields, so as to ensure ventilation and light transmission, good ventilation and light transmission, fertilizer layer constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

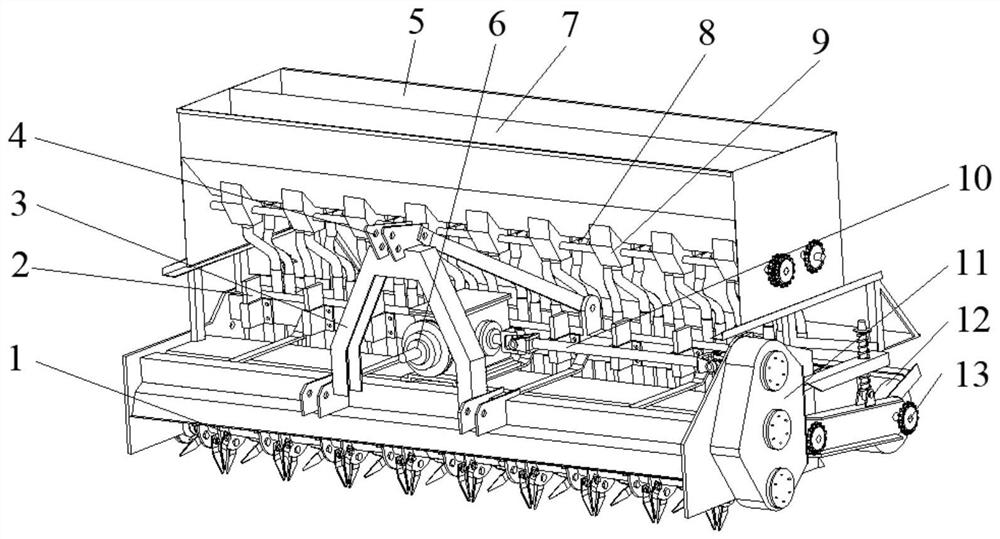

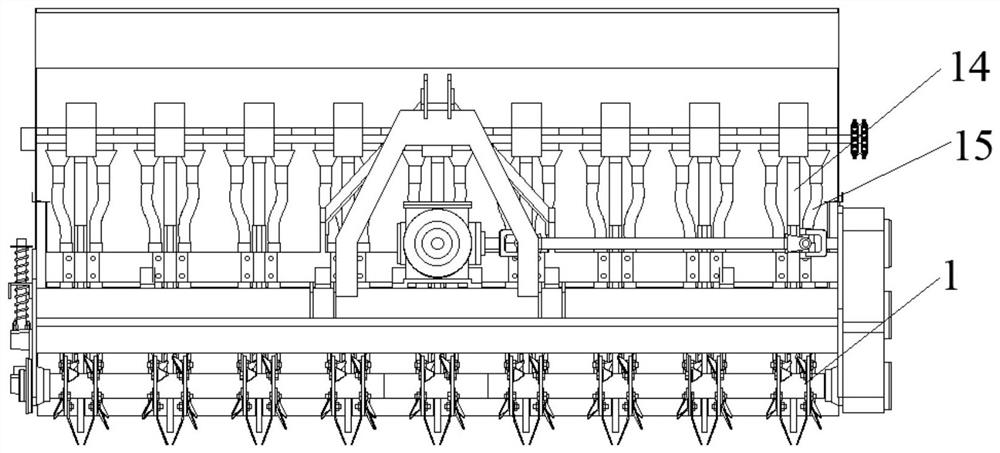

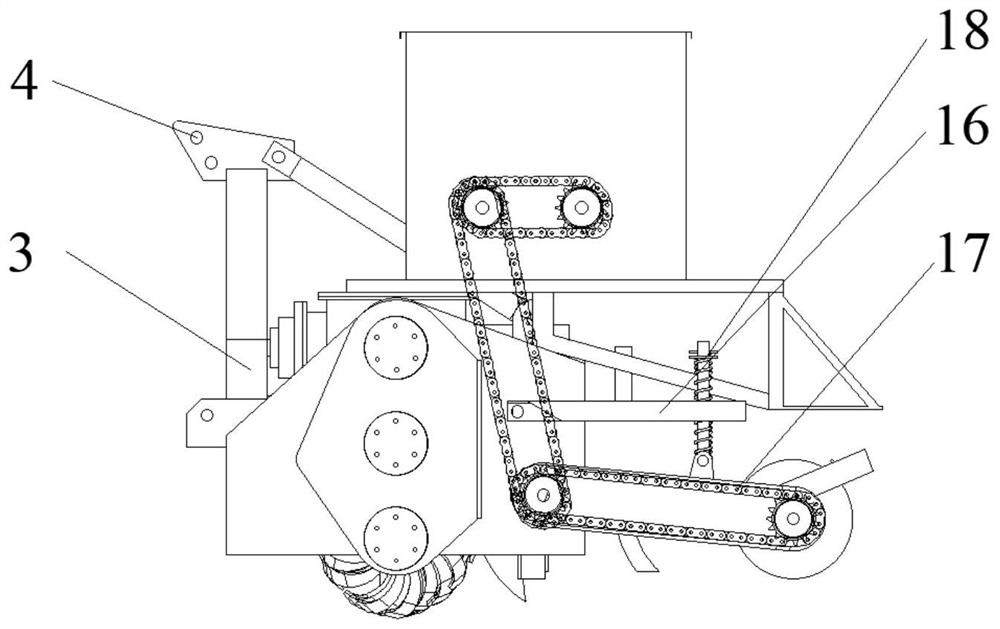

[0026] The accompanying drawings in the embodiments of the present invention will clearly and completely describe the technical solutions in the embodiments of the present invention below.

[0027] like figure 1 , figure 2 , image 3 as well as Figure 4 , the wide and narrow row protective tillage planter with side deep fertilization of the present embodiment mainly consists of a walking frame, a rotary blade shaft 1-1 and a pressing wheel 12 that are rotatably supported on the walking frame, and are connected to the rotary blade shaft 1-1. The rotary tiller 1-2 on the top and the transmission device fixed on the walking support, the seeding box 5, the fertilization box 7, the core share 2-3, and some rotary tiller 1-2 are arranged in pairs by the same group spacing. On the rotary blade shaft 1, the two rotary blades 1-2 in each group of blades are arranged symmetrically with the same blade spacing, and the group spacing is greater than the blade spacing, forming alternat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com