Conveying roller for tempered glass production

A tempered glass and conveying roller technology, which is applied in glass transportation equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of glass and conveying roller slipping, difficult transportation, glass damage, etc., to increase frictional resistance, avoid slipping, The effect of increasing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

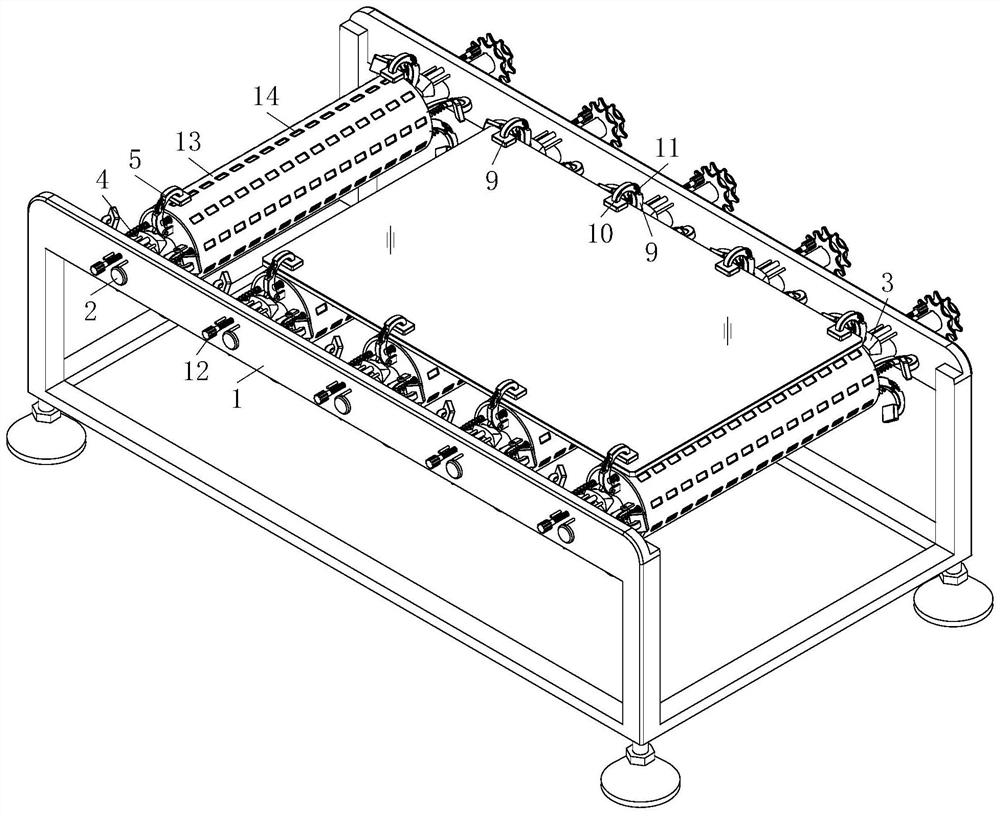

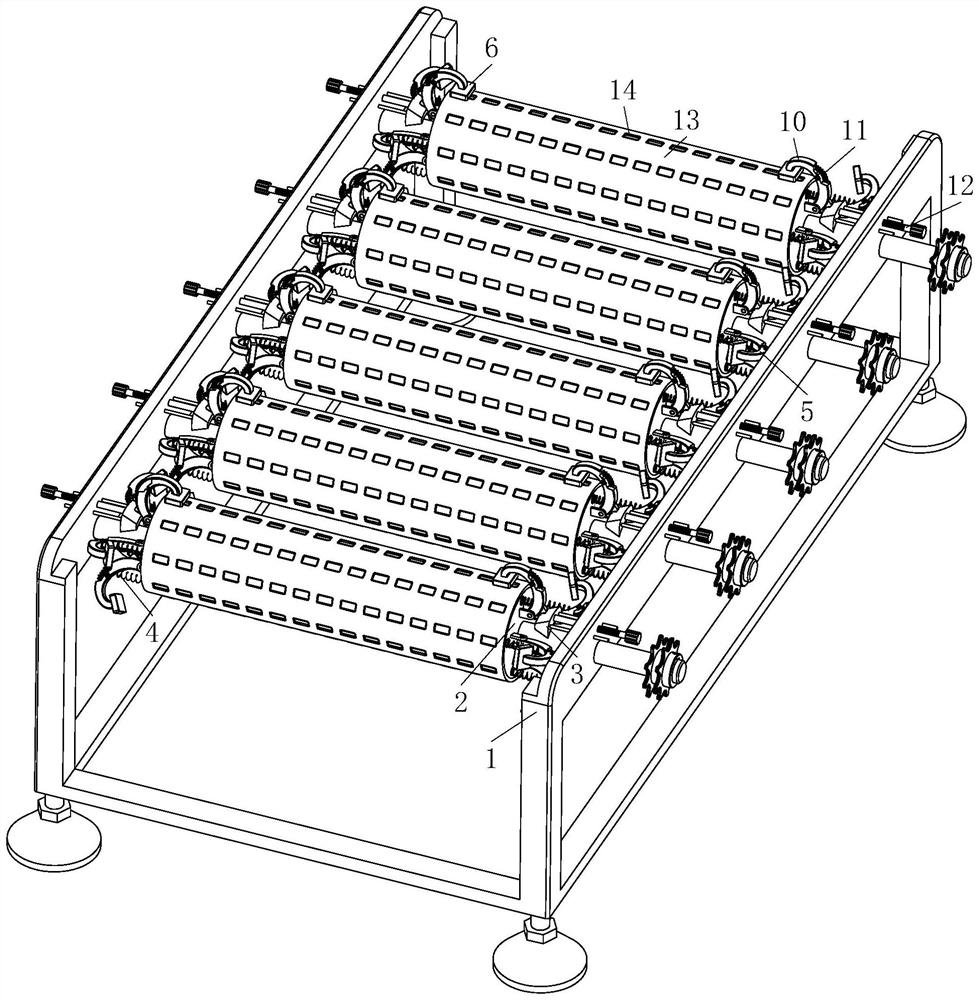

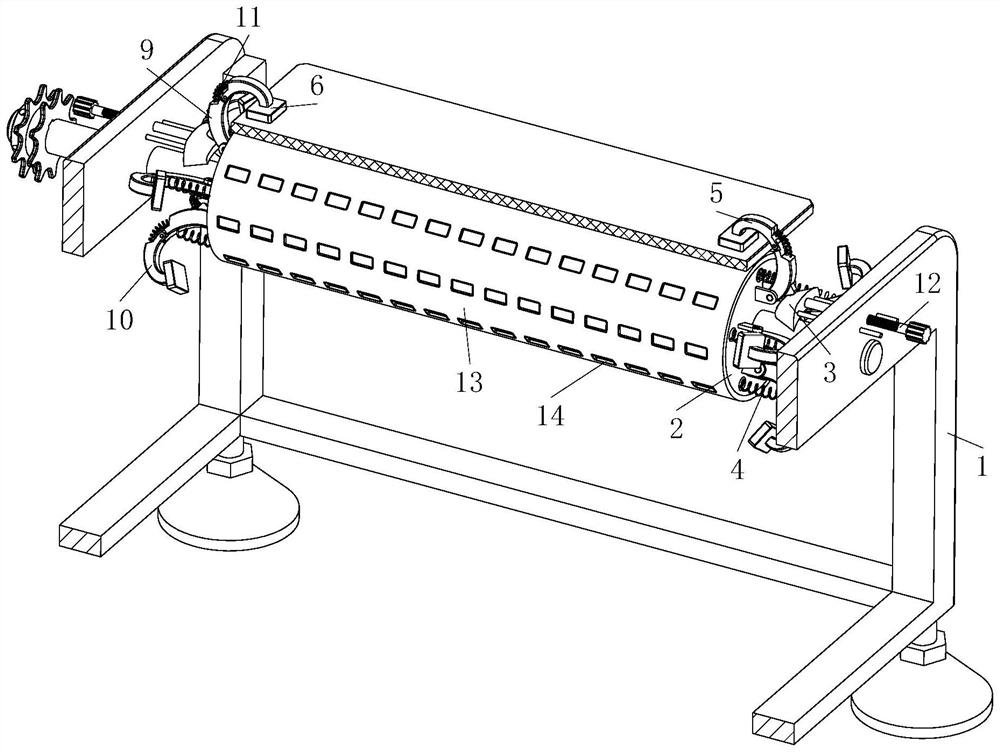

[0038] Such as Figures 1 to 10 Shown; a conveyor roller for tempered glass production, including a mounting frame 1, a rotating roller 2, a limit block 3, a No. 1 spring 4, a pressing frame 5 and a pressing block 6; the mounting frame 1 is evenly spaced There is a rotating roller 2; the rotating roller 2 is rotationally connected with the mounting frame 1; the two ends of the rotating roller 2 are evenly spaced along the circumferential direction with the pressing frame 5; one end of the pressing frame 5 Connected with the end of the rotating roller 2; one side of the pressing frame is provided with a No. 1 spring 4; one end of the No. 1 spring 4 is connected with the pressing frame 5; the other end of the No. 1 spring 4 It is fixedly connected ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap