Silicate microwave dielectric ceramic with low dielectric constant and preparation method thereof

A technology of microwave dielectric ceramics and low dielectric constant, applied in the field of microwave dielectric ceramics, can solve the problems of large negative temperature coefficient of resonant frequency, narrow sintering temperature range, difficult to form ceramics, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

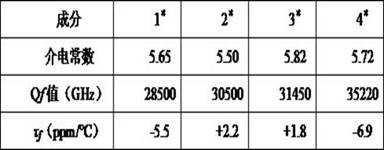

Embodiment 1

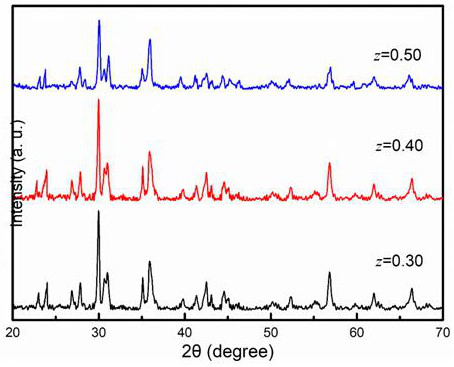

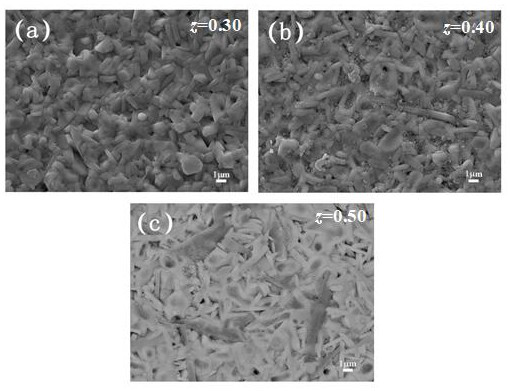

[0025] Step 1, Synthetic Ca 1-x-y / 2 A x Mg 1-y / 2 B y Si 3 o 9 Powder: with CaCO 3 、BaCO 3 , SrCO 3 , Mg(OH) 2 4MgCO 3 ·5H 2 O, ZnO, CoO, MnO, and SiO 2 The powder is the raw material, according to the chemical expression, it is Ca 1-x-y / 2 A x Mg 1-y / 2 B y Si 3 o 9 (A=Sr, Ba; B=Zn, Co, Mn; 0.02≤ x ≤0.10; 0.10≤ y ≤0.50) to form a mixed powder by weighing and batching, wet ball milling for 12 hours, dried and placed in an alumina crucible, and pre-fired in a high-temperature box-type electric furnace at 1050 ° C for 2 hours to obtain Ca 1-x-y / 2 A x Mg 1-y / 2 B y Si 3 o 9 Powder;

[0026] Step 2, synthesis of Ba 5 Si 8 o 21 Powder: with BaCO 3 and SiO 2 Powder is the raw material, according to the chemical expression Ba 5 Si 8 o 21 Weigh the ingredients to form a mixed powder, wet ball mill for 12 hours, put it in an alumina crucible after drying, and pre-fire it in a high-temperature box-type electric furnace at 1050 ° C for 3 hours to obtain Ba...

Embodiment 2

[0034] Step 1, Synthetic Ca 1-x-y / 2 A x Mg 1-y / 2 B y Si 3 o 9 Powder: with CaCO 3 、BaCO 3 , SrCO 3 , Mg(OH) 2 4MgCO 3 ·5H 2 O, ZnO, CoO, MnO, and SiO 2 The powder is the raw material, according to the chemical expression, it is Ca 1-x-y / 2 A x Mg 1-y / 2 B y Si 3 o 9 (A=Sr, Ba; B=Zn, Co, Mn; 0.02≤ x ≤0.10; 0.10≤ y ≤0.50) to form a mixed powder by weighing and batching, wet ball milling for 12 hours, dried and placed in an alumina crucible, and pre-fired in a high-temperature box-type electric furnace at 11150 ° C for 6 hours to obtain Ca 1-x-y / 2 A x Mg 1-y / 2 B y Si 3 o 9 Powder;

[0035] Step 2, synthesis of Ba 5 Si 8 o 21 Powder: with BaCO 3 and SiO 2 Powder is the raw material, according to the chemical expression Ba 5 Si 8 o 21 Weigh the ingredients to form a mixed powder, wet ball mill for 12 hours, put it in an alumina crucible after drying, and pre-fire it in a high-temperature box-type electric furnace at 1150 ° C for 5 hours to obtain Ba ...

Embodiment 3

[0043] Step 1, Synthetic Ca 1-x-y / 2 A x Mg 1-y / 2 B y Si 3 o 9 Powder: with CaCO 3 、BaCO 3 , SrCO 3 , Mg(OH) 2 4MgCO3 ·5H 2 O, ZnO, CoO, MnO, and SiO 2 The powder is the raw material, according to the chemical expression, it is Ca 1-x-y / 2 A x Mg 1-y / 2 B y Si 3 o 9 (A=Sr, Ba; B=Zn, Co, Mn; 0.02≤ x ≤0.10; 0.10≤ y ≤0.50) to form a mixed powder by weighing and batching, wet ball milling for 12 hours, dried and placed in an alumina crucible, and pre-fired in a high-temperature box-type electric furnace at 1100 ° C for 4 hours to obtain Ca 1-x-y / 2 A x Mg 1-y / 2 B y Si 3 o 9 Powder;

[0044] Step 2, synthesis of Ba 5 Si 8 o 21 Powder: with BaCO 3 and SiO 2 Powder is the raw material, according to the chemical expression Ba 5 Si 8 o 21 Weigh the ingredients to form a mixed powder, wet ball mill for 12 hours, put it in an alumina crucible after drying, and pre-fire it in a high-temperature box-type electric furnace at 110°C for 4 hours to obtain Ba 5 S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com