Agricultural robot for agricultural planting and sowing

A robot and seeding mechanism technology, applied in the field of agricultural robots, can solve the problems of affecting the harvest, single function, and inability to limit the number of seeds, and achieve the effects of consistent quantity, cost reduction, and increased practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

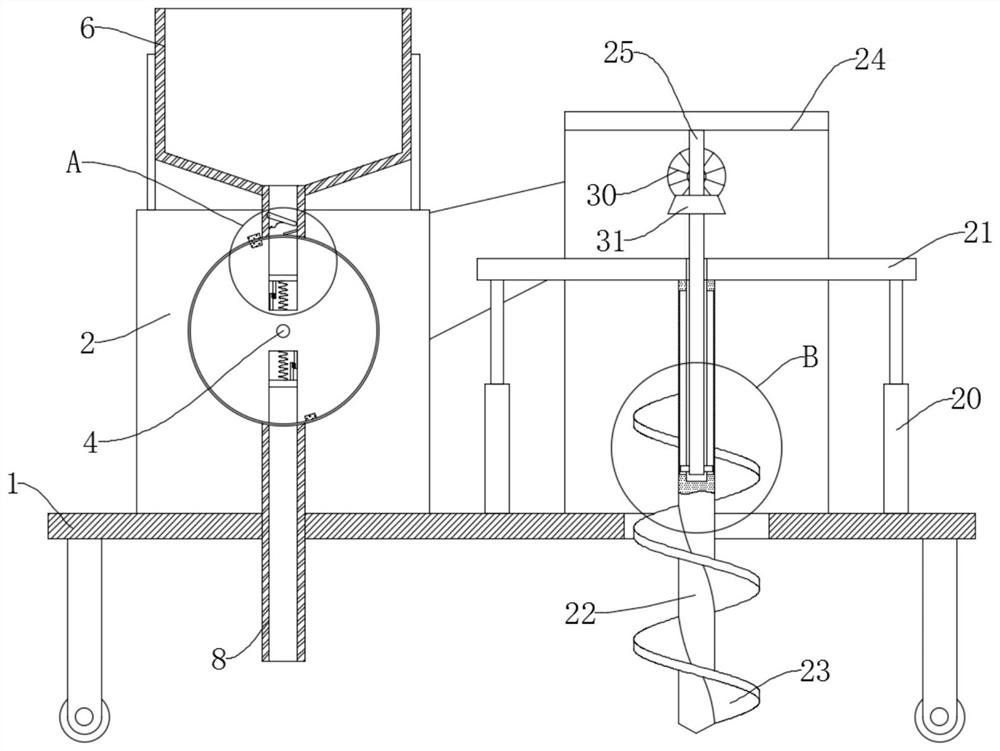

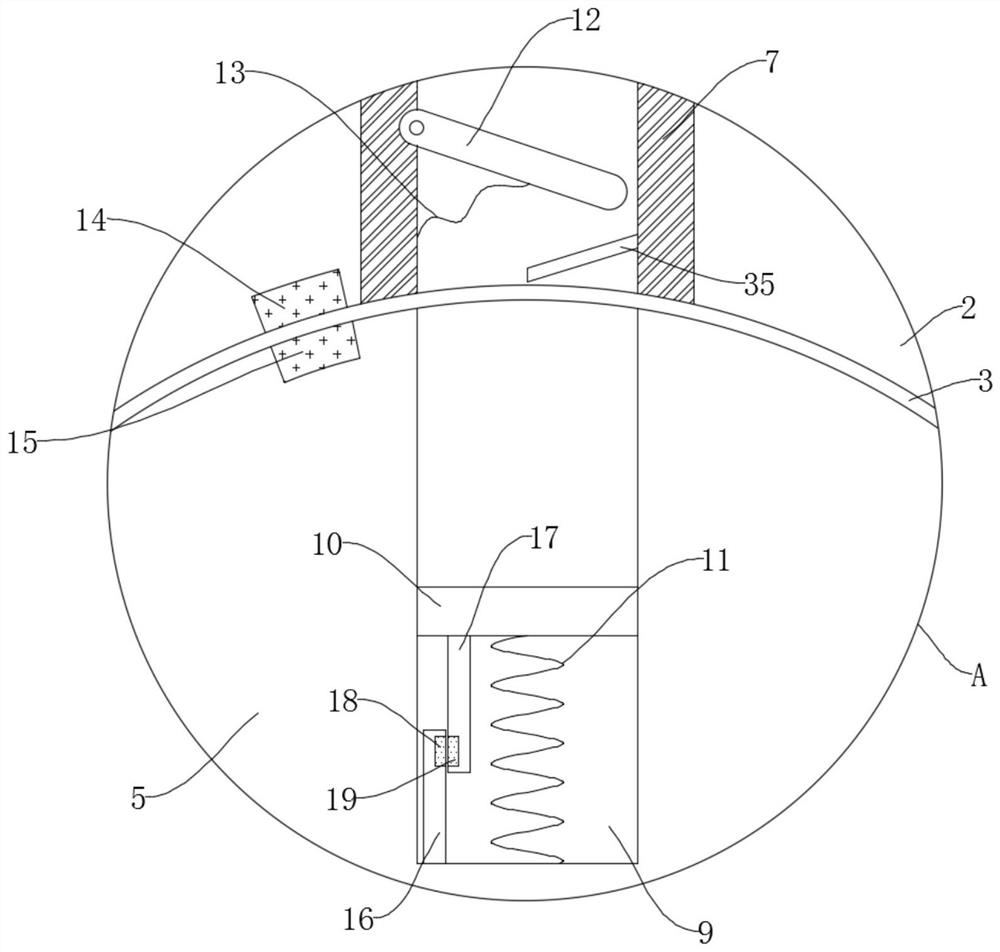

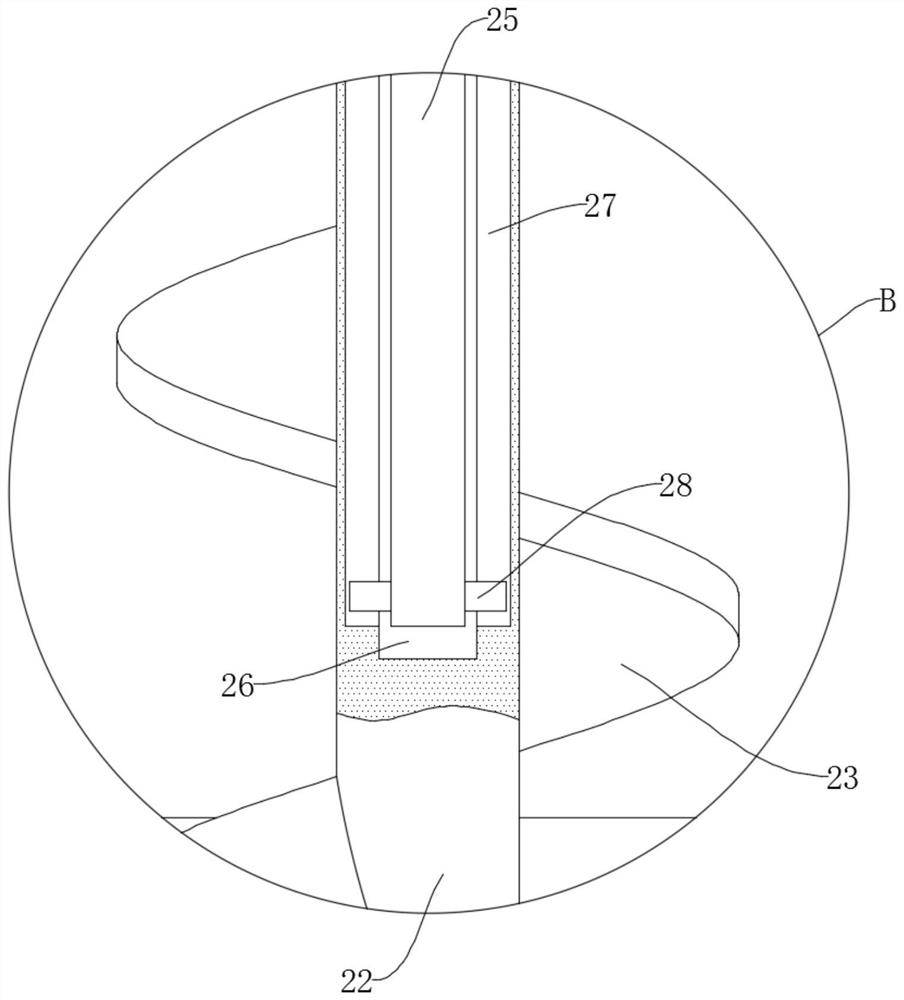

[0022] refer to Figure 1-4 , an agricultural robot for agricultural planting and sowing, comprising a base 1, the upper end of the base 1 is fixedly connected with a fixed plate 2, the fixed plate 2 is provided with a sowing mechanism, the sowing mechanism includes a circular cavity 3 opened in the fixed plate 2, a circular The inner wall of the cavity 3 is connected with the turntable 5 through the rotation of the first rod 4, the upper end of the fixed plate 2 is fixedly connected with the storage bin 6 through the connecting plate, the bottom of the storage bin 6 communicates with the top of the circular cavity 3 through the feed pipe 7, and the circular cavity 3. The bottom is fixedly connected with a discharge pipe 8.

[0023] Two grooves 9 are provided on the side wall directly above and directly below the turntable 5. The inner wall of the groove 9 is slidingly connected with a first plate 10. The side wall of the first plate 10 is elastically connected to the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com