Multi-protein raw material drawing protein, artificial meat food and production process thereof

A technology of drawing protein and production technology, which is applied in the direction of plant protein processing and texturization treatment, to achieve the effect of complete shape, stable output, and reduced surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: Multi-protein raw material drawing protein Ⅰ

[0055] Raw material composition formula: soybean protein isolate 40%, rice protein 13%, pea protein 4%, peanut protein 7%, gluten 20%, soybean meal 10%, corn starch 5%, cysteine 0.10%, calcium carbonate 0.40%, soybean lecithin 0.50%, salt 1%.

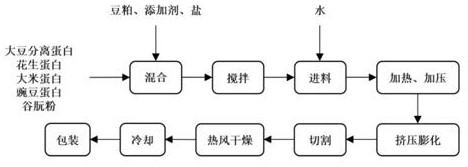

[0056] Such as figure 1 As shown, according to the above ratio, weigh soybean protein isolate, rice protein, pea protein, peanut protein, gluten powder and auxiliary materials, pour them into a mixing mixer, and fully stir for about 3 minutes.

[0057] A twin-screw extruder is used, and the temperature of each zone of the twin-screw extruder is adjusted, respectively, the temperature of the first zone is 44.5°C, the temperature of the second zone is 71.8°C, the temperature of the third zone is 133.1°C, the temperature of the fourth zone is 146.6°C, the temperature of the fifth zone is 151.0°C, and the temperature of the sixth zone is 151.0°C. The temperature in the di...

Embodiment 2

[0060] Example 2: Multi-protein raw material drawing protein II

[0061] Raw material composition formula: soybean protein isolate 38%, rice protein 13%, pea protein 3%, peanut protein 7%, gluten 22%, soybean meal 10%, corn starch 5%, cysteine 0.10%, calcium carbonate 0.40%, soybean lecithin 0.50%, salt 1%.

[0062] In this example, the same production process as in Example 1 was adopted according to the above raw material composition formula, the only difference being the adjustment of the following process parameters, and the multi-protein raw material drawn protein II was produced.

[0063] The temperature of each zone of the twin-screw extruder is 40°C for zone 1, 68°C for zone 2, 125°C for zone 3, 140°C for zone 4, 145°C for zone 5, 145°C for zone 6, 145°C for zone 7 and 8 Zone temperature 138°C. The feeding rate of the liquid feed port is 9.7L / h, and the screw speed is 25hz.

Embodiment 3

[0064] Example 3: multi-protein raw material drawing protein

[0065] Raw material composition formula: soybean protein isolate 40%, rice protein 13%, pea protein 4%, peanut protein 7%, gluten 20%, soybean meal 10%, corn starch 5%, cysteine 0.10%, calcium carbonate 0.40%, soybean lecithin 0.50%, salt 1%.

[0066] In this example, the same production process as in Example 1 was adopted according to the above raw material composition formula, and the only difference was the adjustment of the following process parameters, and the multi-protein raw material drawn protein III was produced.

[0067] The temperature of each zone of the twin-screw extruder is 47°C for zone 1, 74°C for zone 2, 135°C for zone 3, 150°C for zone 4, 155°C for zone 5, 155°C for zone 6, 155°C for zone 7 and 8 Zone temperature 145°C. The feeding speed of the liquid feed port is 10.2L / h, and the screw speed is 30hz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com